A kind of isothermal extrusion processing method of square tube aluminum alloy profile

An aluminum alloy profile, isothermal extrusion technology, applied in the field of warm extrusion processing, can solve problems such as cracking, mold outlet temperature affecting profile size accuracy, structure and performance, distortion, etc., to achieve uniform distribution, stable strength and plasticity, and guarantee uniformity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

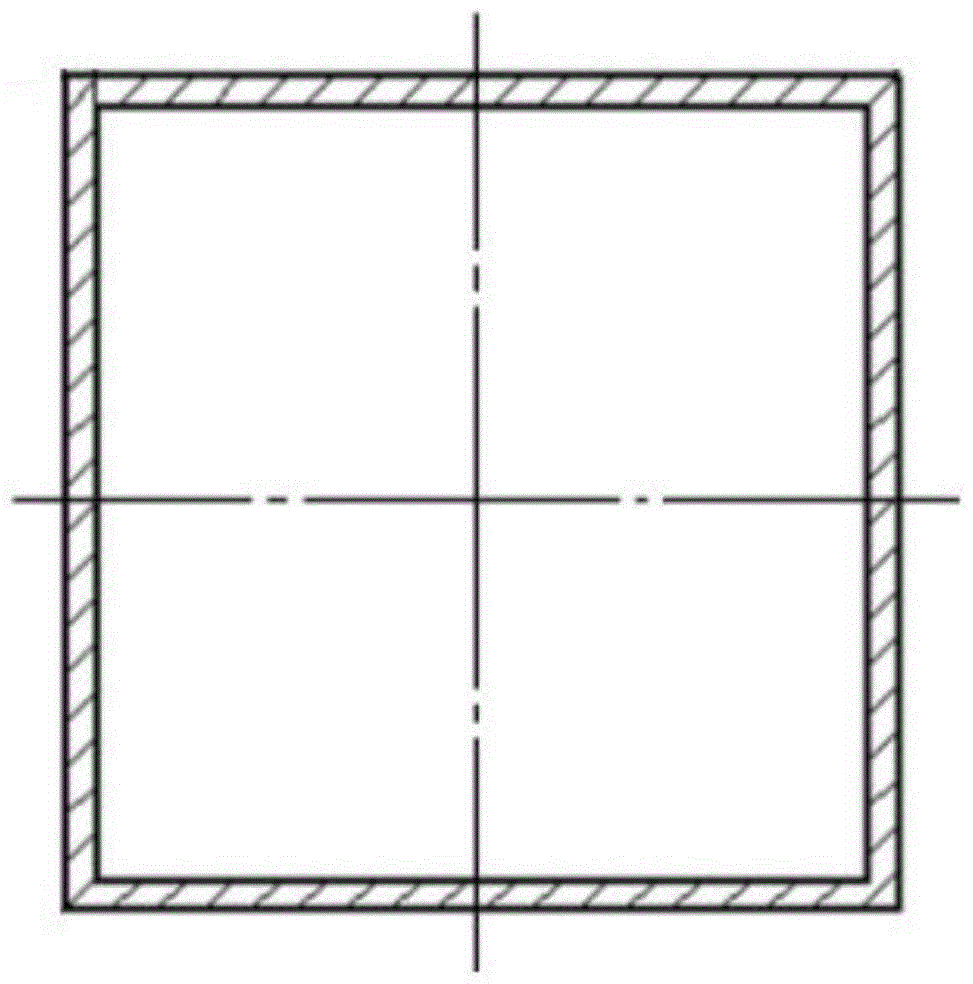

[0032] An isothermal extrusion processing method for a square tube aluminum alloy profile, comprising the following steps:

[0033] Step 1. According to the specifications of the square tube aluminum alloy profiles to be processed, the extrusion equipment is selected, and the size of the extrusion billet is calculated. The diameter of the extrusion billet is 200mm, and the length is 250mm.

[0034] Step 2. According to the extrusion production experience and data of the square tube aluminum alloy profile to be processed, determine that the heating temperature of the extrusion billet is 440°C, the temperature of the extrusion die is 430°C, the temperature of the extrusion pad is 420°C and The temperature of the extrusion barrel was 410°C.

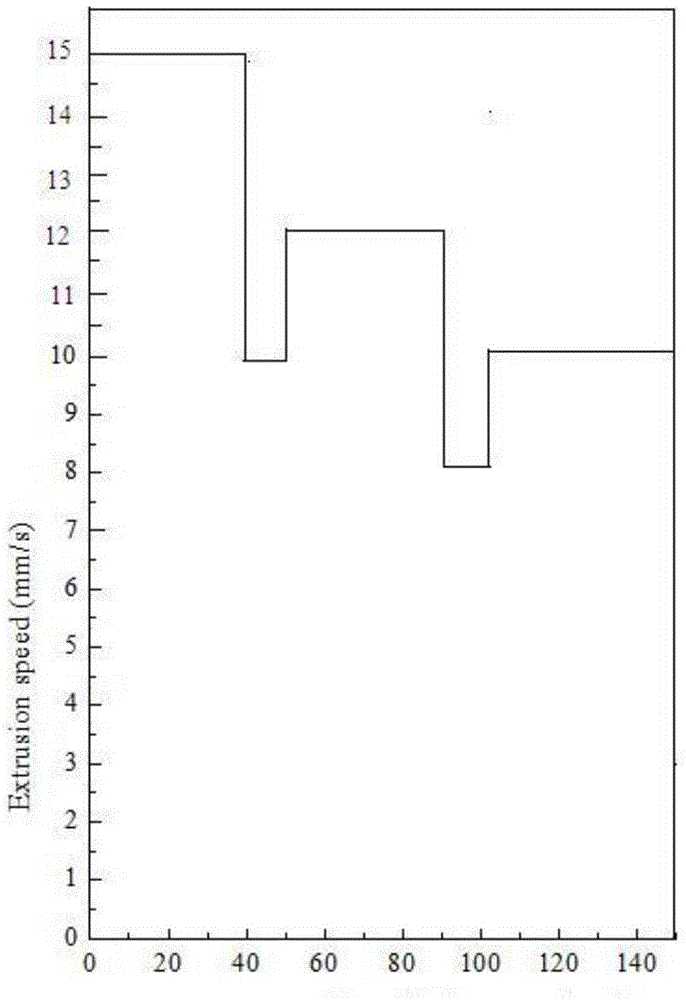

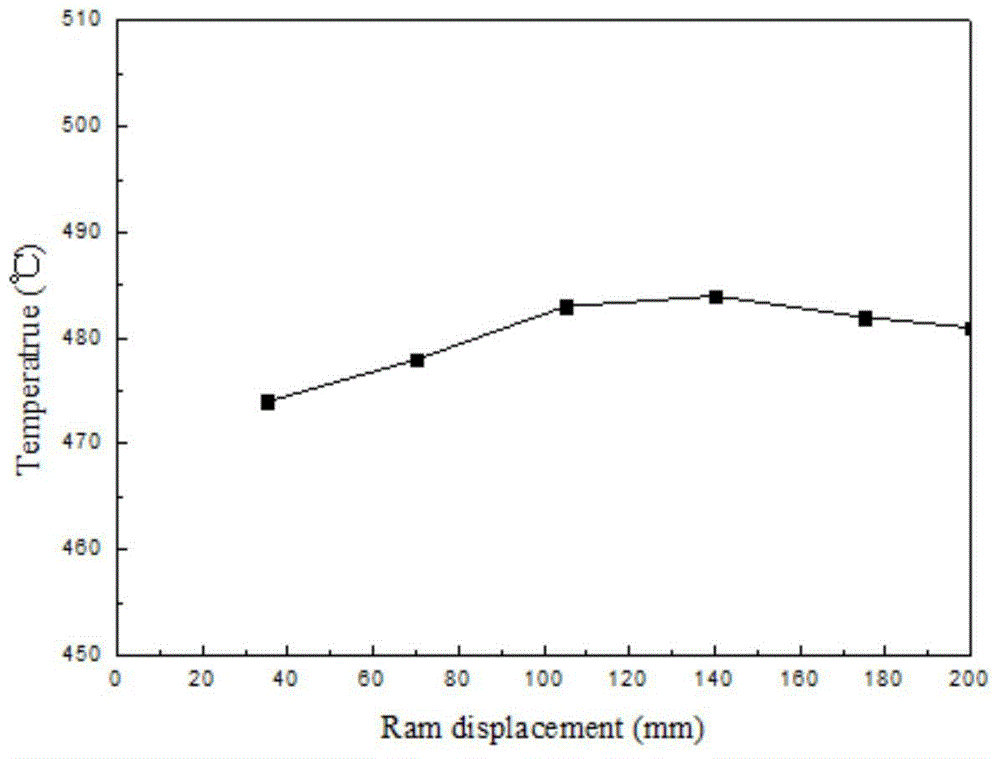

[0035] Step 3. Set the segmented speed change model of the extrusion rod in the control system of the extrusion equipment, and divide the total extrusion stroke of 150mm into 5 sections. When the extrusion stroke is 0-40mm, the extrusion spe...

Embodiment 2

[0038] An isothermal extrusion processing method for a square tube aluminum alloy profile, comprising the following steps:

[0039] Step 1. According to the specifications of the square tube aluminum alloy profiles to be processed, the extrusion equipment is selected, and the size of the extruded billet is calculated. The diameter of the extruded billet is 190 mm, and the length is 240 mm.

[0040] Step 2. According to the extrusion production experience and data of the square tube aluminum alloy profiles to be processed, determine that the heating temperature of the extrusion billet is 435°C, the temperature of the extrusion die is 425°C, the temperature of the extrusion pad is 415°C and The temperature of the extrusion barrel was 405°C.

[0041]Step 3. Set the segmented speed change model of the extrusion rod in the control system of the extrusion equipment, and divide the total extrusion stroke of 150mm into 5 sections. When the extrusion stroke is 0-40mm, the extrusion spe...

Embodiment 3

[0044] An isothermal extrusion processing method for a square tube aluminum alloy profile, comprising the following steps:

[0045] Step 1. According to the specifications of the square tube aluminum alloy profiles to be processed, the extrusion equipment is selected, and the size of the extrusion billet is calculated. The diameter of the extrusion billet is 210mm, and the length is 260mm.

[0046] Step 2. According to the extrusion production experience and data of the square tube aluminum alloy profile to be processed, it is determined that the heating temperature of the extrusion billet is 445°C, the temperature of the extrusion die is 435°C, and the temperature of the extrusion pad is 425°C and extrusion barrel temperature was 415°C.

[0047] Step 3. Set the segmented speed change model of the extrusion rod in the control system of the extrusion equipment, and divide the total extrusion stroke of 150mm into 5 sections. When the extrusion stroke is 0-40mm, the extrusion spe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com