Laser Cladding of Ni-based Alloy+b on Q550 Steel 4 c enhanced phase method

A laser cladding and base alloy technology, which is applied in the coating process and coating of metal materials, can solve the problem of insufficient bonding between the reinforcement phase and the base alloy, the increase in the rate of cracked pores in the cladding layer, and the increase in the dilution rate of the cladding layer etc. to achieve the effects of reducing powder loss and increasing production costs, increasing service life of workpieces, and increasing wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

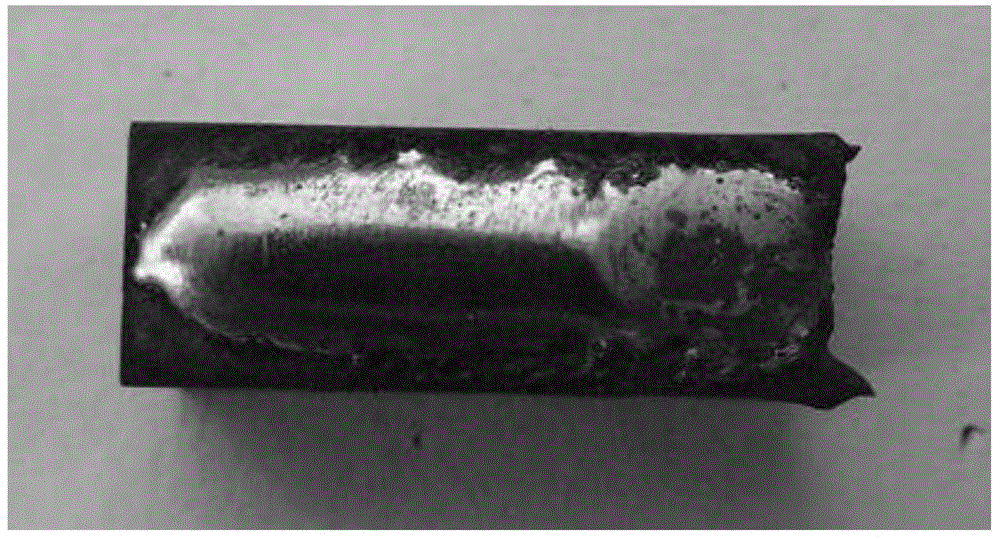

[0030] On a Q550 high-strength steel sample with a size of 10mm×10mm×25mm, laser cladding Ni-based alloy powder plus B 4 C enhanced phase.

[0031] The specific process steps are as follows:

[0032] 1) Grinding the surface of the Q550 steel sample to remove oil and rust;

[0033] 2) The Ni-based powder for cladding is a Ni60 series self-fluxing alloy with a particle size of 250 mesh. The mass percentage of each component of the Ni60 alloy powder is: C 0.85%, Si 0.45%, B 3.6%, Cr 16%, Fe 14%, The rest is Ni. B 4 C reinforcement phase has a purity of 99% and a particle size of 200 mesh. B 4 Add 5% of C reinforcement layer powder according to the mass fraction, the total amount of mixed powder is 100g, take 95g of Ni60 alloy powder and 5g of B 4 C powder was uniformly mixed in a powder mixer for 2 hours, then dried at 250°C for 30 minutes, and put into a powder feeder for use.

[0034] 3) Fix the sample on the workbench, perform laser cladding on the sample area of 10mm...

Embodiment 2

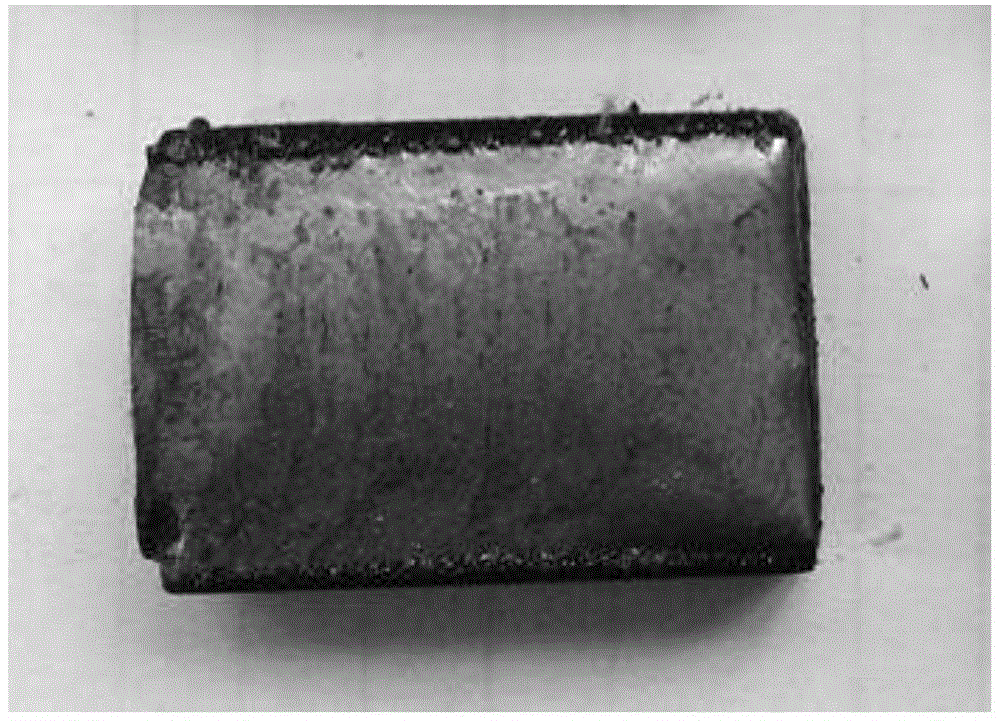

[0041] On a Q550 high-strength steel sample with a size of 10mm×20mm×30mm, laser cladding Ni-based alloy powder+B 4 C strengthening phase.

[0042] The specific process steps are as follows:

[0043] 1) Grinding the surface of Q550 steel sample 20×30mm before laser cladding to remove oil and rust;

[0044] 2) The Ni-based powder for cladding is a Ni60 series self-fluxing alloy with a particle size of 250 mesh. The mass percentage of each component of the Ni60 alloy powder is: C 0.85%, Si 0.45%, B 3.6%, Cr 16%, Fe 14%, The rest is Ni. B 4 C reinforcement phase has a purity of 99% and a particle size of 200 mesh. B 4 Add 8% of C reinforcement phase powder by mass fraction, and the total amount of mixed powder is 200g. Get 184g Ni60 alloy powder and 16g B 4 C powder was uniformly mixed in a powder mixer for 2 hours, then dried at 250°C for 30 minutes, and put into a powder feeder for use.

[0045] 3) Fix the sample on the workbench, perform laser cladding on the sample ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com