Technology and device for treating organic waste gas with activated carbon by means of nitrogen heating and vacuum desorption

A technology of organic waste gas and activated carbon, which is used in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of high economic operation cost, difficult waste water treatment, large steam consumption, etc., to reduce treatment costs and achieve no waste water. The effect of simple pollution and treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

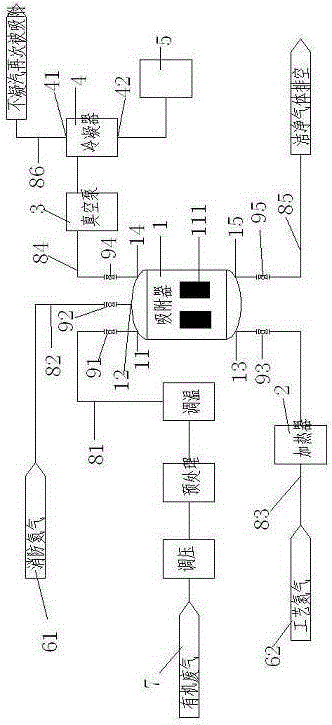

[0036] A nitrogen heating vacuum desorption activated carbon organic waste gas treatment process based on the above-mentioned device is characterized in that it includes a pretreatment stage, an adsorption stage, a desorption stage and a recovery stage. The pretreatment stage is: taking into account the absorber's bearing Capacity and process requirements, before the organic waste gas enters the adsorber, it is necessary to adjust the pressure, pretreatment and temperature adjustment of the organic waste gas. The throttling and pressure reducing valve throttles and discharges, and enters the buffer tank to buffer and reduce pressure until it reaches 9kpa. The organic waste gas after pressure regulation still contains more solid particles, which need to be filtered through a filter to filter out solid particles, and then The temperature is adjusted through the heat exchanger. In order to improve the adsorbability of organic waste gas, the temperature needs to be adjusted to 45°C...

Embodiment 2

[0042] Based on the above-mentioned activated carbon organic waste gas treatment process of nitrogen heating vacuum desorption, it is characterized in that it includes a pretreatment stage, an adsorption stage, a desorption stage and a recovery stage. The pretreatment stage is: first, the organic waste gas discharged from industrial production Exhaust gas pressure regulation, pressurized by a pressurized fan, or throttled by a throttle and pressure reducing valve into a buffer tank for buffering and decompression, until the pressure of the organic waste gas reaches 8kpa, and the organic waste gas after the pressure adjustment also contains more Solid particles need to be filtered through a filter to remove solid particles, and then the temperature is adjusted through a heat exchanger. In order to improve the adsorbability of organic waste gas, its temperature needs to be adjusted to 855°C;

[0043] The adsorption stage is: the organic waste gas that has undergone pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com