Plasma processing device and electrostatic chuck thereof and manufacturing method of electrostatic chuck

A processing device and plasma technology, applied in semiconductor/solid-state device manufacturing, circuits, discharge tubes, etc., can solve the problem of uneven temperature distribution of electrostatic chucks, difficult electrostatic chuck temperature uniformity, and uneven heating of electrostatic chucks And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

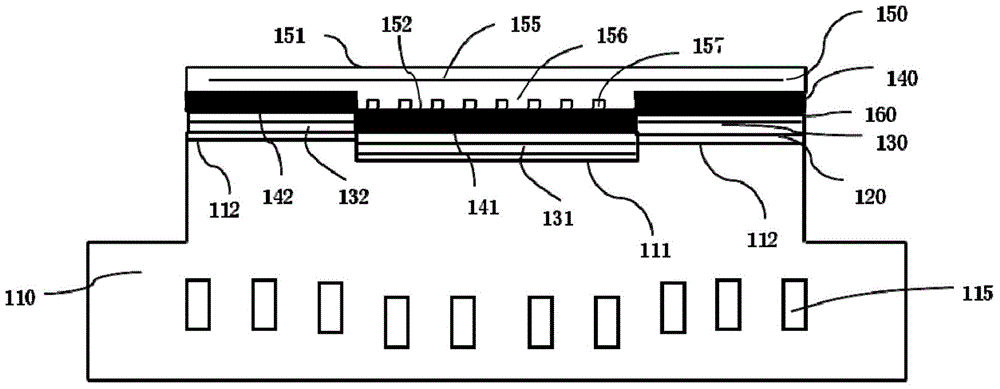

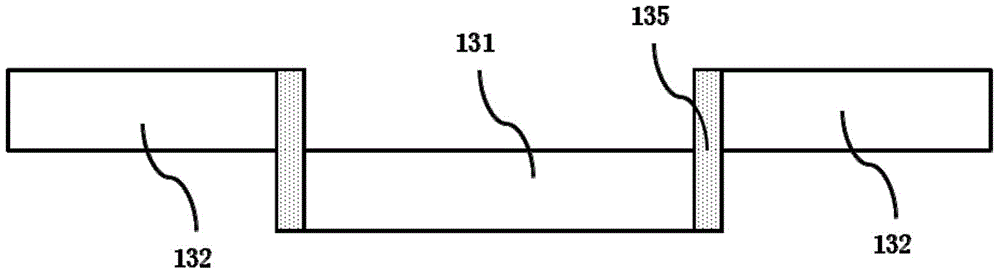

[0039] The specific embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings.

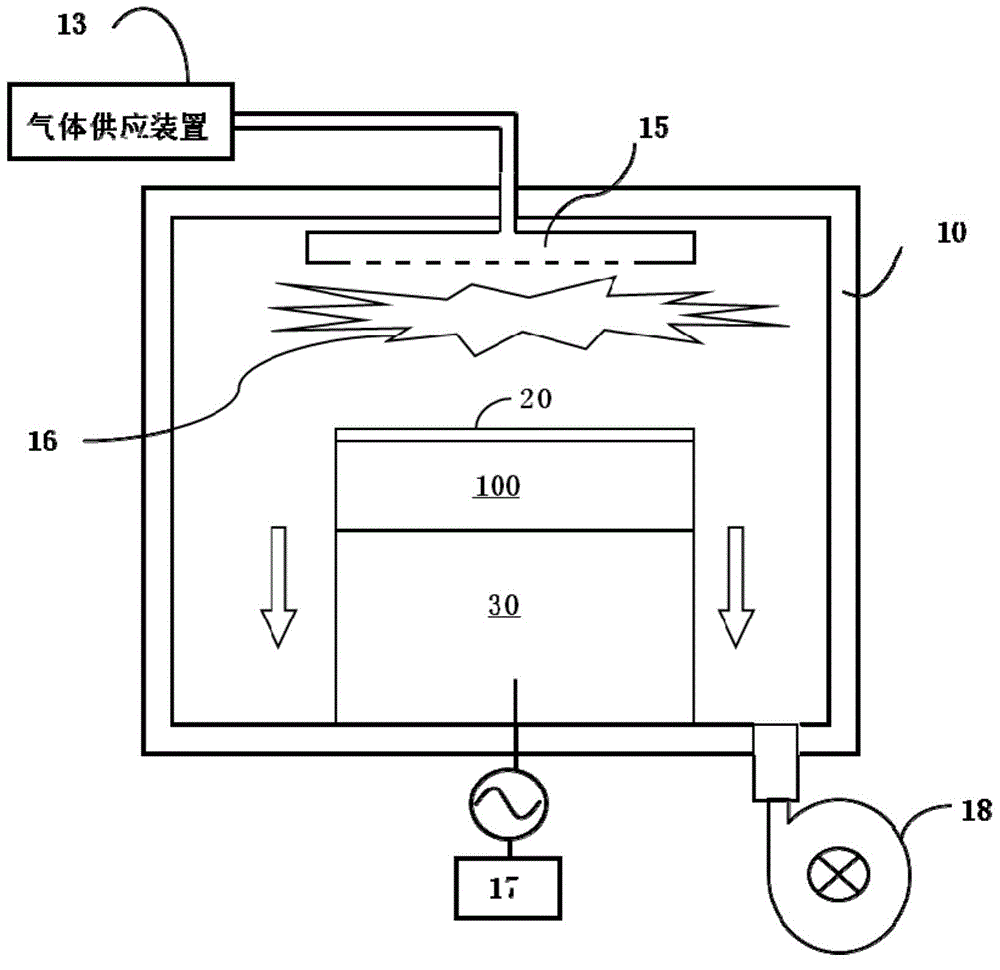

[0040] The technical scheme described in the invention is applicable to capacitively coupled plasma reaction chambers or inductively coupled plasma reaction chambers, as well as other plasma reaction chambers that use electrostatic chucks to support substrates to be processed. Exemplary, figure 1A schematic diagram of the structure of the plasma reaction chamber of the present invention is shown; the plasma reaction chamber is a capacitively coupled plasma reaction chamber, and any deformations made by those skilled in the art through the technical solutions disclosed in the present invention without creative labor belong to protection scope of the present invention.

[0041] figure 1 A schematic diagram of the structure of a plasma reaction chamber is shown, including a roughly cylindrical reaction chamber 10, and upper and lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com