Mesoporous tricobalt tetroxide nanorod, preparation method thereof, supercapacitor electrode material and electrode

A technology of cobalt tetroxide and supercapacitor, applied in hybrid capacitor electrodes, cobalt oxide/cobalt hydroxide, nanotechnology, etc., can solve the problems of poor cyclability, small capacitance, application limitations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

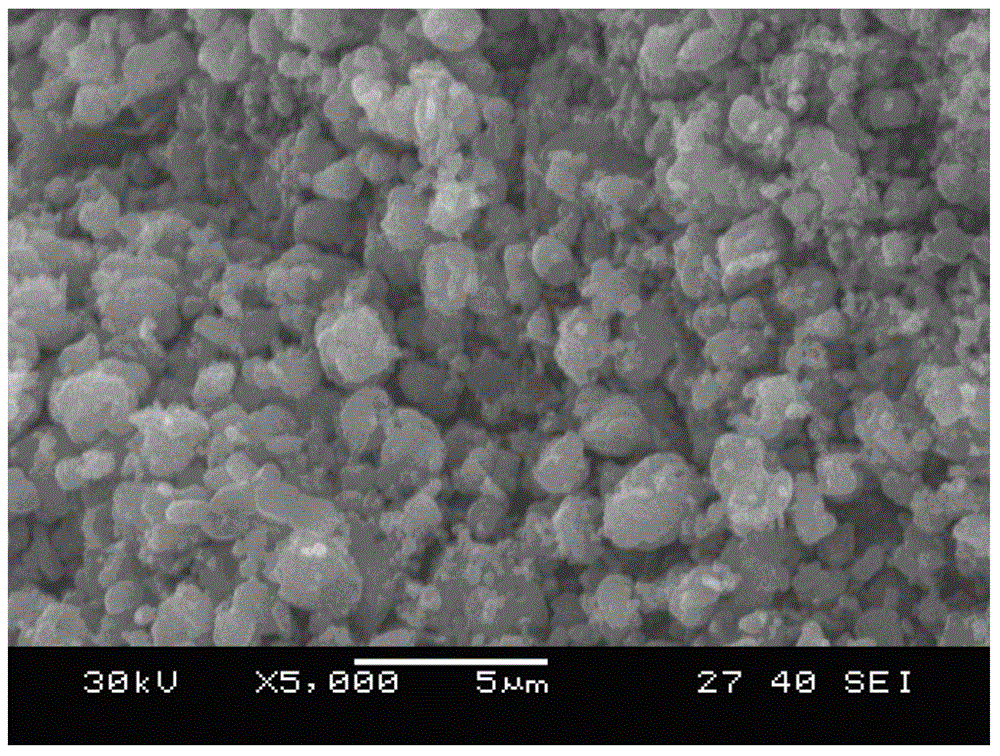

[0031] The invention provides a method for preparing mesoporous cobalt trioxide nanorods, the preparation method comprising:

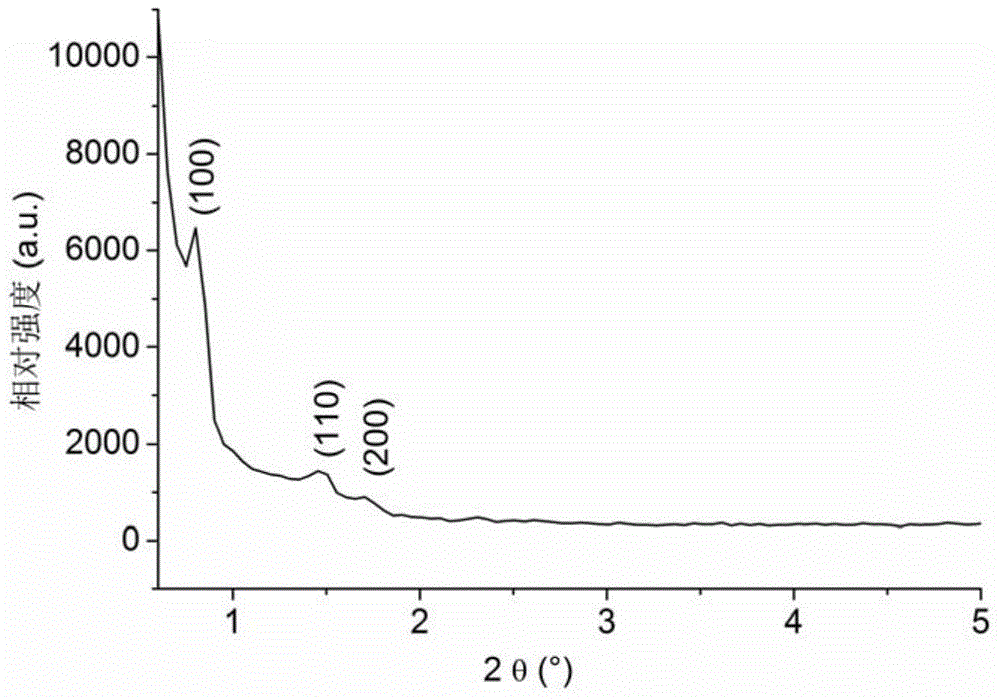

[0032] a, preparation of rod-shaped mesoporous silica;

[0033] b. Mixing the rod-shaped mesoporous silica with a cobalt salt solution, and removing the solvent to obtain a cobalt salt-rod-shaped mesoporous silica load;

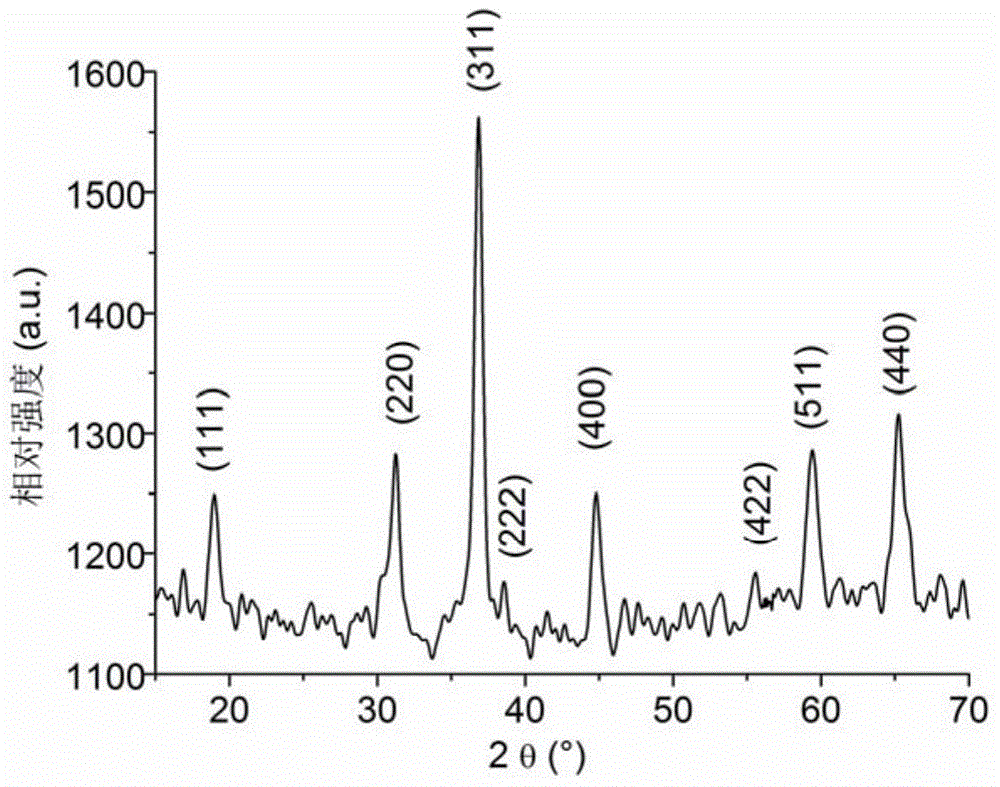

[0034] c. Decomposing the cobalt salt-rod-shaped mesoporous silica load to obtain a tricobalt tetroxide-rod-shaped mesoporous silica composite;

[0035] d. Carrying out metathesis reaction of the cobalt trioxide-rod-shaped mesoporous silicon dioxide composite with lye to prepare mesoporous cobalt trioxide nanorods.

[0036]In step b of the present invention, the specific amount of each substance can be selected within a wide range, but in order to load more cobalt salts in the mesoporous channels of rod-shaped mesoporous silica, preferably, in step b , relative to 1 mole part of rod-shaped mesoporous silica, the amount of cobalt sal...

Embodiment 1

[0063] a. Prepare rod-shaped mesoporous silica according to the method reported in "High-yield synthesis of periodic mesoporous silica rods and their replication to mesoporous carbon rods":

[0064] At 38°C, 1.6g (0.32mmol) of surfactant P123 and 2.2g (30mmol) of KCl were dissolved in 60g of hydrochloric acid solution with a concentration of 2mol L-1, stirred for 30min, and then added under vigorous stirring 4.2 g (20 mmol) of TEOS. Among them, P123, KCl, HCl, H 2 The mass ratio of O and TEOS is 0.02:1.5:6:166:1. After the mixture was vigorously stirred for 8 min, the stirring was stopped, and it was allowed to stand at 38°C for one day. Then, it was hydrothermally reacted at 130°C for 24 hours. Heating rate 1℃·min -1 ) under roasting for 4h to remove the organic matter and obtain rod-shaped mesoporous silica.

[0065] b. Preparation of cobalt salt-rod-shaped mesoporous silica load D1:

[0066] 0.5g rod-shaped mesoporous SiO 2 Disperse in 5mL with a concentration of 0.8m...

Embodiment 2

[0076] 0.4 g of mesoporous cobalt trioxide nanorods A2 were prepared according to the method of Example 1, except that the calcination temperature in step c was 180°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com