Method and system for recovering copper, zinc and cyanide in cyanidation gold extraction of high-copper gold mines

A cyanide and gold ore technology, applied in the direction of improving process efficiency, can solve problems such as environmental pollution, unsuitability for high copper-containing gold ore, etc., and achieve economic benefits, reduce the amount of cyanide, and reduce the amount of investment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

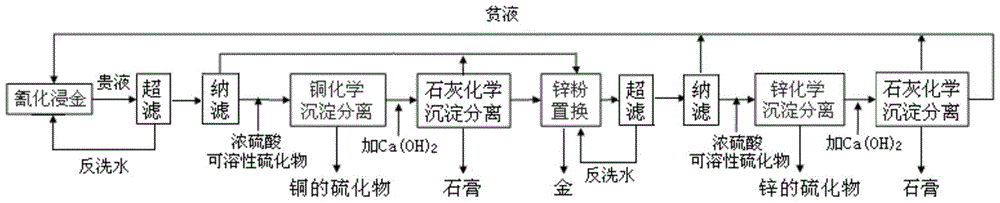

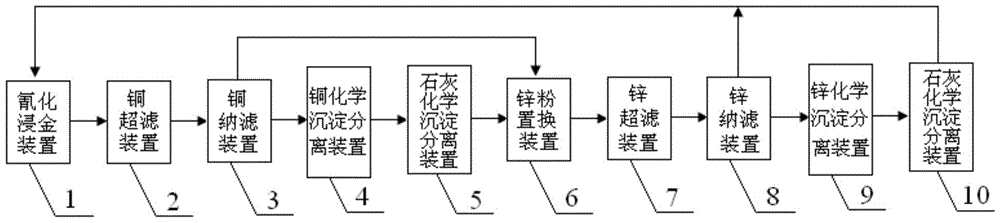

[0034] The process flow diagram of the method for reclaiming copper zinc and cyanide in the cyanidation gold extraction of high-copper gold ore of the present embodiment is as follows figure 1 As shown, the method includes steps performed in the following order.

[0035] 1. Gold leaching in cyanide

[0036] Wet grinding of gold placer (copper and gold symbiotic ore, copper content is about 16%), so that the ore particles below 200 mesh in the gold ore account for more than 90%, and then concentrated, and the concentration of the pulp is 45% About, add lime milk to the pulp as a protective base and maintain the pH of the pulp at about 12; under stirring conditions, use a sodium cyanide solution with a concentration of 0.3% and an oxygen content of 8 mg / L in the cyanide pool to The above pulp is leached, and after leaching for 48 hours, the formed leachate is filtered to produce gold-containing precious liquid.

[0037] 2. Ultrafiltration and Nanofiltration

[0038] The ultra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com