LED-UV photo-curing solder resist ink and preparation method thereof

A solder resist ink and photocuring technology, which is applied in inks, household utensils, applications, etc., can solve the problems of slow curing speed, poor anti-adhesion performance, and limited popularization and application, and achieve fast curing speed and good anti-adhesion performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

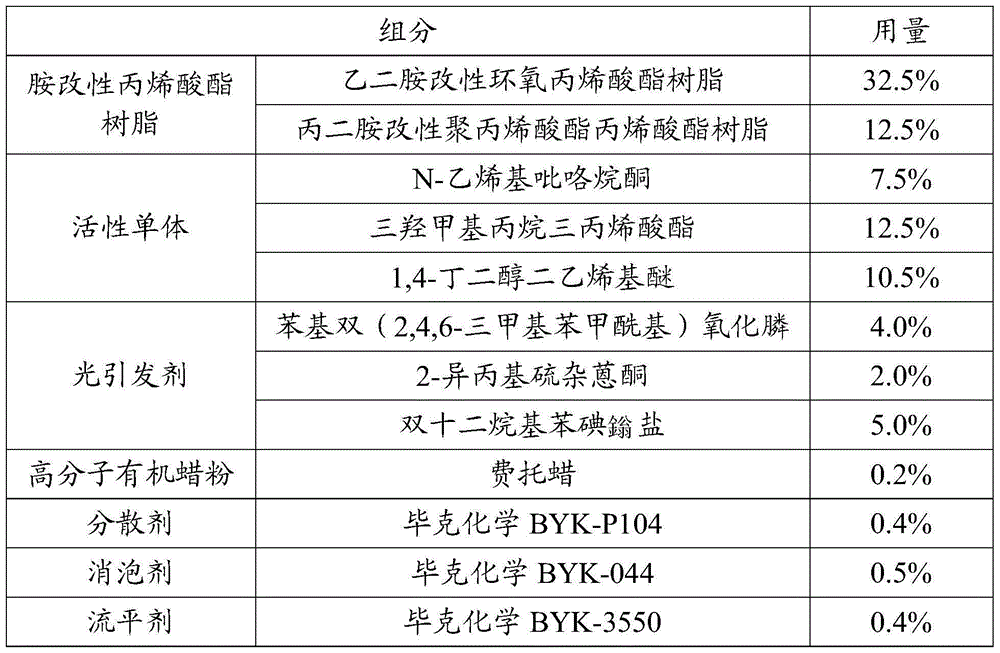

[0031] Embodiment 1: LED-UV photocurable solder resist ink of the present invention

[0032] Weigh each component according to the following proportions:

[0033]

[0034]

[0035] Wherein, the vinyl ether content in the ethylenediamine-modified epoxy acrylate resin is 0.8mmol / g, and the acrylate content is 2.5mmol / g; the vinyl ether content in the propylenediamine-modified polyacrylate acrylate resin It is 3 mmol / g, and the acrylate content is 1 mmol / g.

[0036] Put the amine-modified acrylate resin, active monomer, photoinitiator, polymer organic wax powder, dispersant, pigment and filler into the dispersion bucket in proportion, and disperse at a speed of 1000-1500rpm with a high-speed disperser for 1-2 Mix the raw materials evenly; use a three-roll mill to fully grind the dispersed raw materials to a fineness of 5-10 μm; add leveling agents, defoamers, and rheological additives to the ground raw materials. A high-speed disperser disperses for 1-2 hours at a rotatio...

Embodiment 2

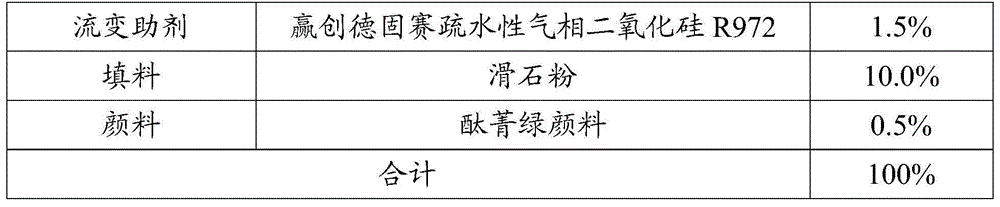

[0037] Embodiment 2: LED-UV photocurable solder resist ink of the present invention

[0038] Weigh each component according to the following proportions:

[0039]

[0040]

[0041] Wherein, the vinyl ether content in the ethylenediamine modified epoxy acrylate resin is 1.4mmol / g, the acrylate content is 2.2mmol / g; The vinyl ether content in the butanediamine modified polyurethane acrylate resin is 2.8 mmol / g, the acrylate content is 1.3mmol / g; the vinyl ether content in the butanediamine modified polyester acrylate resin is 0.8mmol / g, and the acrylate content is 2.5mmol / g.

[0042] Put the amine-modified acrylate resin, active monomer, photoinitiator, polymer organic wax powder, dispersant, pigment and filler into the dispersion bucket in proportion, and disperse at a speed of 1000-1500rpm with a high-speed disperser for 1-2 Mix the raw materials evenly; use a three-roll mill to fully grind the dispersed raw materials to a fineness of 5-10 μm; add leveling agents, defoa...

Embodiment 3

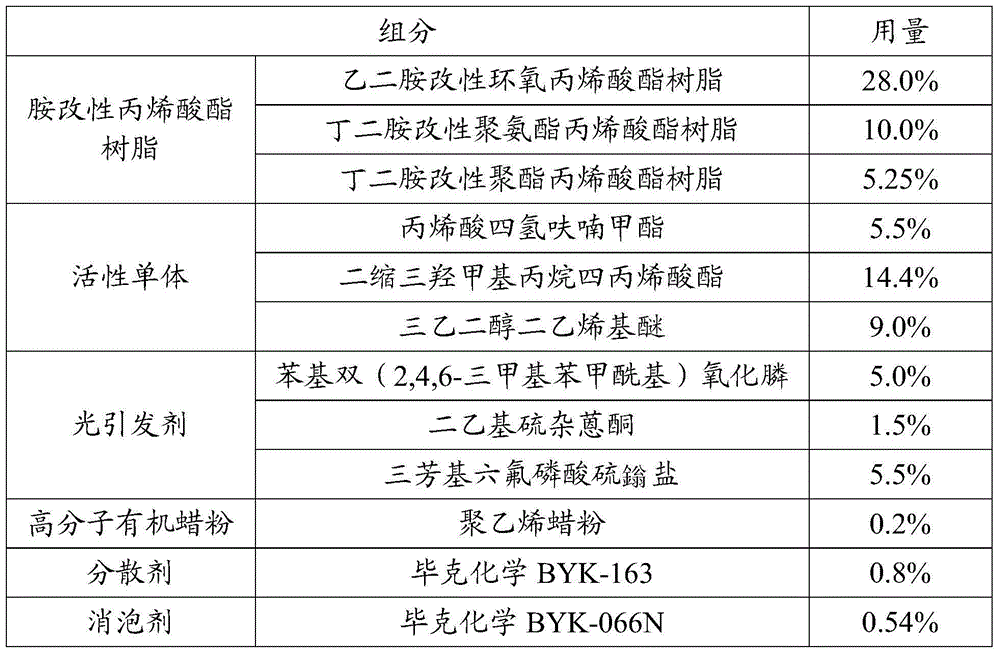

[0043] Embodiment 3: LED-UV photocurable solder resist ink of the present invention

[0044] Weigh each component according to the following proportions:

[0045]

[0046]

[0047] Wherein, the vinyl ether content in the propylenediamine-modified epoxy acrylate resin is 2.5 mmol / g, and the acrylate content is 3.0 mmol / g.

[0048] Put the amine-modified acrylate resin, active monomer, photoinitiator, polymer organic wax powder, dispersant, pigment and filler into the dispersion bucket in proportion, and disperse at a speed of 1000-1500rpm with a high-speed disperser for 1-2 Mix the raw materials evenly; use a three-roll mill to fully grind the dispersed raw materials to a fineness of 5-10 μm; add leveling agents, defoamers, and rheological additives to the ground raw materials. A high-speed disperser disperses for 1-2 hours at a rotational speed of 500-1000 rpm to uniformly mix the raw materials, and then filters to obtain the LED-UV photocurable solder resist ink of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com