C5/C6 alkane low-temperature isomerization method

A low-temperature isomerization and isomerization technology, which is applied in the field of light hydrocarbon isomerization, can solve the problems of increasing coking tendency, reducing the isomerization rate of C5 hydrocarbons, and reducing the isomerization rate, so as to reduce heating and cooling energy consumption. , the effect of increasing the octane number of the product and increasing the isomerization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

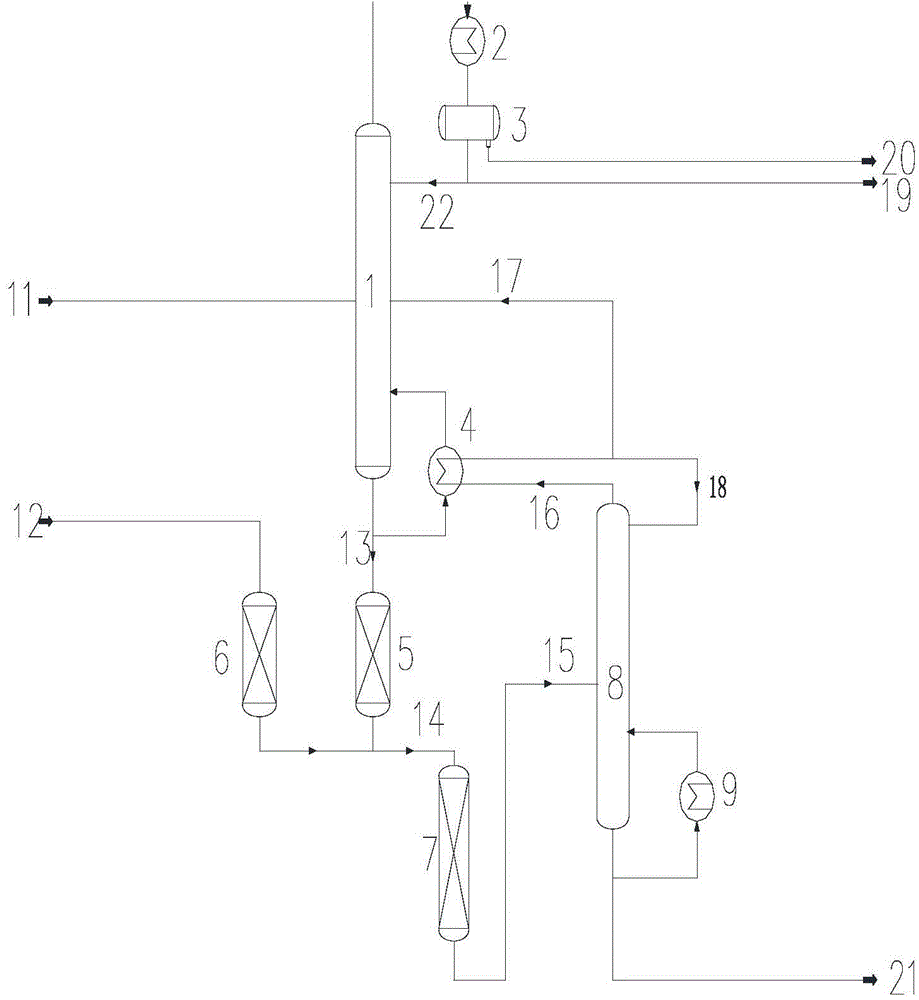

[0031] A C5 / C6 alkane low-temperature isomerization method, the process flow is as follows figure 1 Shown. Using a commercially available low-temperature isomerization catalyst to perform C5 / C6 alkane isomerization includes the following steps:

[0032] (1) The C5 / C6 raw material 11 from outside (see Table 1 for properties) first enters the isopentane tower 1, which is equipped with a top condenser 2 and a bottom reboiler 3. Water 20 is removed and separated into isopentane fraction 21 and deisopentane fraction 13. The isopentane fraction 19 goes to the downstream process. The removed water 20 goes to the subsequent treatment device, and the reflux 22 from the top of the isopentane tower is returned to the isopentane tower 1.

[0033] (2) The deisopentane fraction 13 enters the deisopentane fraction dryer 5 for drying, and the moisture content of the dried deisopentane fraction reaches the feed condition of the isomerization reactor 7.

[0034] (3) The hydrogen 12 from outside th...

Embodiment 2

[0048] A C5 / C6 alkane low-temperature isomerization method adopts the following steps:

[0049] 1) The raw material enters the isopentane tower to remove water and separate into isopentane fraction and isopentane fraction. The volume content of isopentane in the separated isopentane fraction reaches more than 75%, and the isopentane fraction is removed Downstream process, remove water to follow-up treatment device;

[0050] 2) The deisopentane fraction is dried by a dryer to control the moisture content to be less than 1ppm;

[0051] 3) The external hydrogen enters the dryer to dry, and the moisture content is controlled to be less than 1ppm;

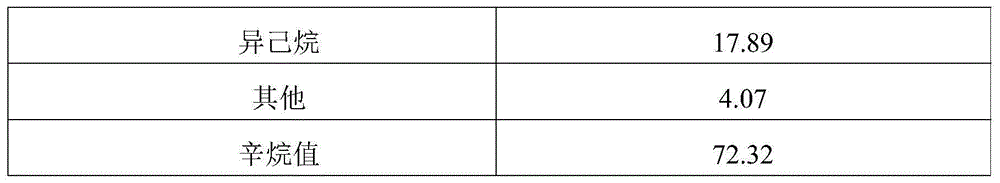

[0052] 4) After the dried deisopentane fraction is mixed with hydrogen, it enters the isomerization reactor, where the isomerization reaction is carried out under low temperature conditions. In this example, the reaction temperature is 150°C. The catalyst is supported by γ-Al 2 O 3 , The metal component Pt and halogen Cl, wherein the mass perc...

Embodiment 3

[0055] 1) The raw material enters the isopentane tower to remove water and separate into isopentane fraction and isopentane fraction. The volume content of isopentane in the separated isopentane fraction reaches more than 75%, and the isopentane fraction is removed Downstream process, remove water to follow-up treatment device;

[0056] 2) The deisopentane fraction is dried by a dryer to control the moisture content to be less than 1ppm;

[0057] 3) The external hydrogen enters the dryer to dry, and the moisture content is controlled to be less than 1ppm;

[0058] 4) After the dried deisopentane fraction is mixed with hydrogen, it enters the isomerization reactor, where the isomerization reaction is carried out under low temperature conditions. In this example, the reaction temperature is 180°C. The catalyst is supported by γ-Al 2 O 3 , The metal component Pt and halogen Cl composition, wherein the mass percentage of the metal component Pt is 1.5%, the mass percentage of the halogen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com