Beverage filling method and device

一种灌装装置、饮料的技术,应用在同步装置、清洁方法和用具、化学仪器和方法等方向,能够解决吹塑成型机设备复杂化、杀菌效果降低、难杀菌等问题,达到防止过度吸附过氧化氢、减少使用量和温度、减少照射剂量的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach 〉

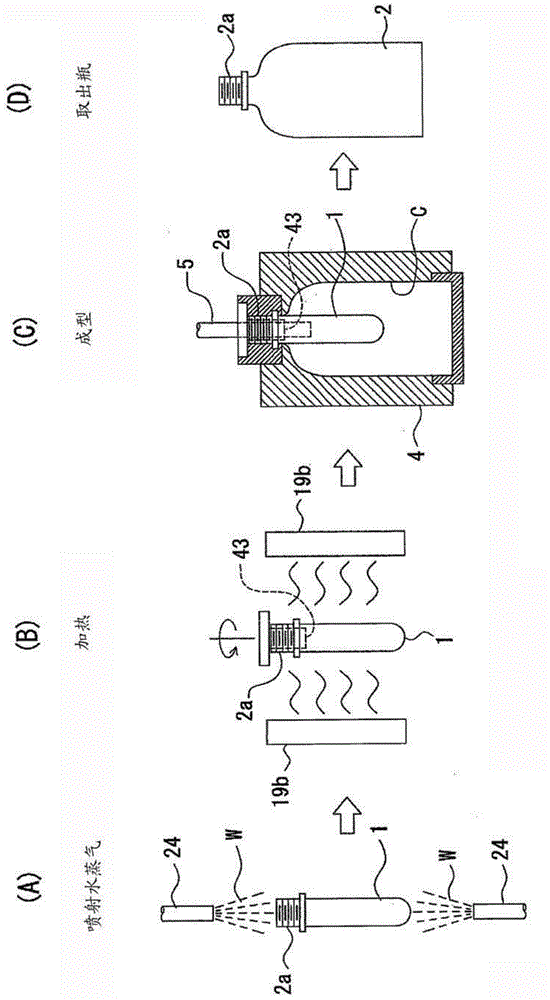

[0072] According to the online production system of the first embodiment, it is possible to manufacture figure 1 package shown.

[0073] Such as figure 1 As shown, the package has a bottle 2 as a container and a bottle cap 3 as a cap.

[0074] In this embodiment, the bottle 2 is manufactured using PET, but it is not limited to PET, and the bottle 2 may be manufactured using other resins such as polypropylene and polyethylene. The mouth 2a of the bottle 2 is formed with an external thread 2b.

[0075] The bottle cap 3 is formed by injection molding of resin such as polypropylene, and the internal thread 3a is formed simultaneously with the molding of the bottle cap 3 .

[0076] The bottle 2 is filled with the sterilized beverage a in a state where the inside of the bottle 2 has been sterilized in advance. After the beverage a is filled, the mouth 2a of the bottle 2 is covered with the bottle cap 3, and the mouth 2a of the bottle 2 is sealed by screwing the internal and exte...

no. 2 approach 〉

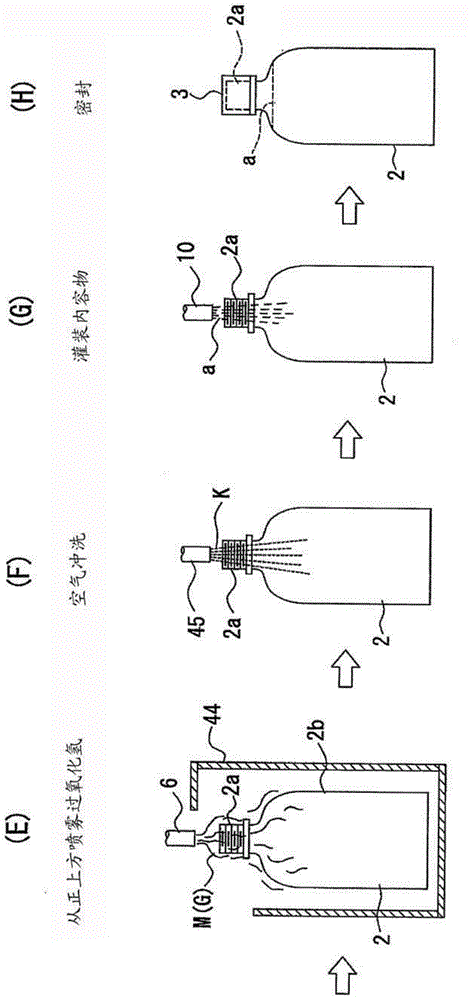

[0154] Such as Image 6 As shown in (E), in the second embodiment, as figure 2 The bottle 2 taken out from the mold 4 as shown in (D) is rinsed with sterile hot water H to perform main sterilization. exist Image 6 In (E), reference numeral 46 denotes a nozzle for hot water rinsing that sprays sterile hot water H. As shown in FIG. The temperature of the hot water H is maintained within a range such that the bottle 2 does not deform.

[0155] Bottle 2 is the same as the first embodiment, in figure 2 The stage of the preform 1 shown in (B) is sprayed with water vapor and then heated in a humid heat state to pre-sterilize almost all microorganisms except bacterial spores. Therefore, by this hot water rinsing, bacteria surviving in the molding stage of the above-mentioned bottle 2 are sterilized.

[0156] Such as Image 6 Shown in (F), beverage a is filled in bottle 2 after being rinsed by hot water, and as Image 6 Cap 3 on the bottle as shown in (G).

[0157] The filli...

no. 3 approach 〉

[0163] According to the online production system of the third embodiment, it is also possible to manufacture figure 1 package shown.

[0164] The above-mentioned bottle 2 forms a container in the same procedure as described in the first embodiment, and forms a package through beverage filling and sealing. However, in the first embodiment, as figure 2 As shown in (A), water vapor W is sprayed from the nozzle 24 to the preform 1. In contrast, in the third embodiment, as Figure 8 As shown in (A), hydrogen peroxide mist or gas L is sprayed from the nozzle 24 to the preform 1 .

[0165] From the hydrogen peroxide mist or gas L sprayed from this nozzle 24, utilize and Figure 4 Shown mist generator 7 is generated by the mist generator of the same structure.

[0166] By spraying hydrogen peroxide mist or gas L, the surface of the preform 1 is attached and formed at 0.0035 μL / cm 2 ~0.35μL / cm 2 Coagulation film of hydrogen peroxide in conversion of 35% by weight in the range. I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion amount | aaaaa | aaaaa |

| Adhesion amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com