System and method for preparing microcapsules

A preparation system and microcapsule technology, applied in the field of materials, can solve the problems of the influence of material activity, the difficulty of encapsulating solid materials by emulsification method, and the complicated operation of self-assembly technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

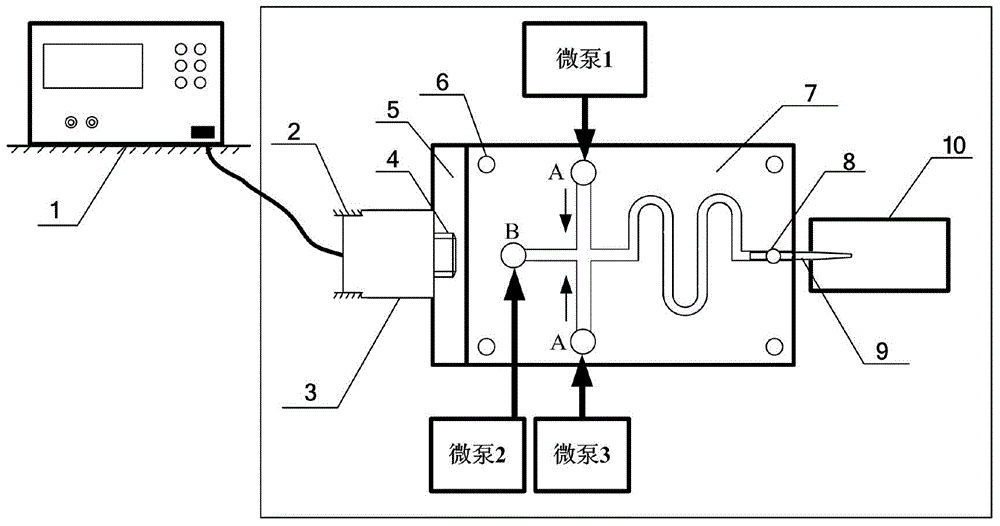

[0029] The preparation of embodiment 1 single-component microcapsules

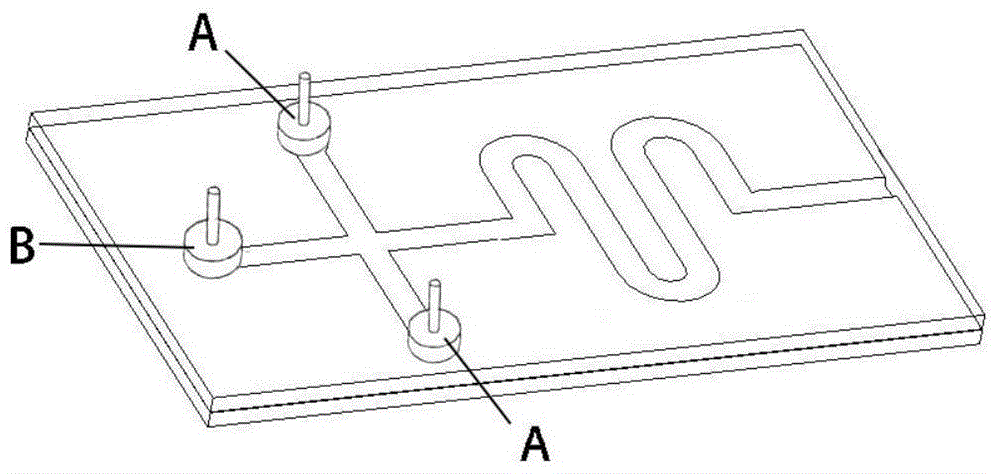

[0030] First prepare the single-component microfluidic chip 7, then insert the micro-spray head 9 into the micro-fluidic chip 7 for output, and fix the micro-spray head through the set screw 8 of the spray head, and seal the port with UV glue; The four corners of the microfluidic chip 7 are fixed on the plane of the chip mounting bracket 5 with four screws 6, and the tail of the mounting bracket 5 is connected with the piezoelectric ceramic 3 by connecting bolts, and the piezoelectric ceramic 3 is fixed on the fixing seat 2, and the piezoelectric ceramic Ceramic 3 is connected with driving power 1 . The single-component solution is pumped into the microfluidic chip 7 from the inlet B of the first core material solution on the chip through the micropump, and the sodium alginate solution of the wall material is pumped into the microfluidic chip 7 from the inlet A of the wall material solution through the mic...

Embodiment 2

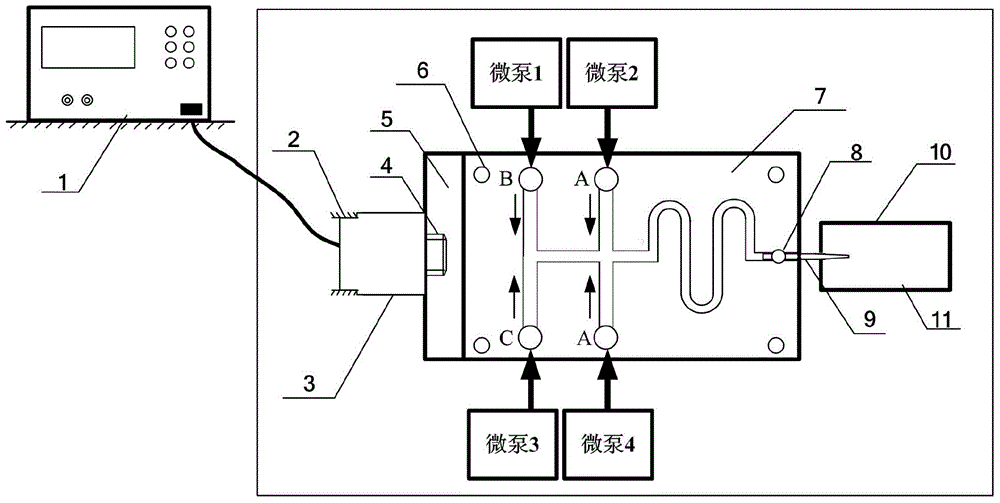

[0031] The preparation of embodiment 2 two-component microcapsules

[0032] First prepare the two-component microfluidic chip 7, then insert the micro-spray head 9 into the micro-fluidic chip 7 for output, and fix the micro-spray head through the set screw 8 of the print head, and seal the port with UV glue; The four corners of the microfluidic chip 7 are fixed on the plane of the chip mounting bracket 5 with four screws 6, and the tail of the mounting bracket 5 is connected with the piezoelectric ceramic 3 by connecting bolts, and the piezoelectric ceramic 3 is fixed on the fixing seat 2, and the piezoelectric ceramic Ceramic 3 is connected with driving power 1 . The two-component solution is pumped into the microfluidic chip 7 from the first core material solution inlet B and the second core material solution inlet C on the chip through the micropump, and the wall material sodium alginate solution is pumped from the wall material solution inlet A through the micropump. Inse...

Embodiment 3 3

[0033] The preparation of embodiment 3 three-component microcapsules

[0034]First prepare the two-component microfluidic chip 7, then insert the micro-spray head 9 into the micro-fluidic chip 7 for output, and fix the micro-spray head through the set screw 8 of the print head, and seal the port with UV glue; The four corners of the microfluidic chip 7 are fixed on the plane of the chip mounting bracket 5 with four screws 6, and the tail of the mounting bracket 5 is connected with the piezoelectric ceramic 3 by connecting bolts, and the piezoelectric ceramic 3 is fixed on the fixing seat 2, and the piezoelectric ceramic Ceramic 3 is connected with driving power 1 . The three-component solutions are pumped into the microfluidic chip 7 from the first core material solution inlet B, the second core material solution inlet C, and the third core material solution inlet D on the chip through the micropump, and the wall material sodium alginate solution is passed through the microflu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com