Polyurethane fiber

一种聚氨酯纤维、聚氨酯类的技术,应用在聚氨酯类纤维领域,能够解决香味嗜好性高、香料残留、尚无可得到具备香气持续性的布帛的报道等问题,达到耐久性优良、劣化的程度小的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

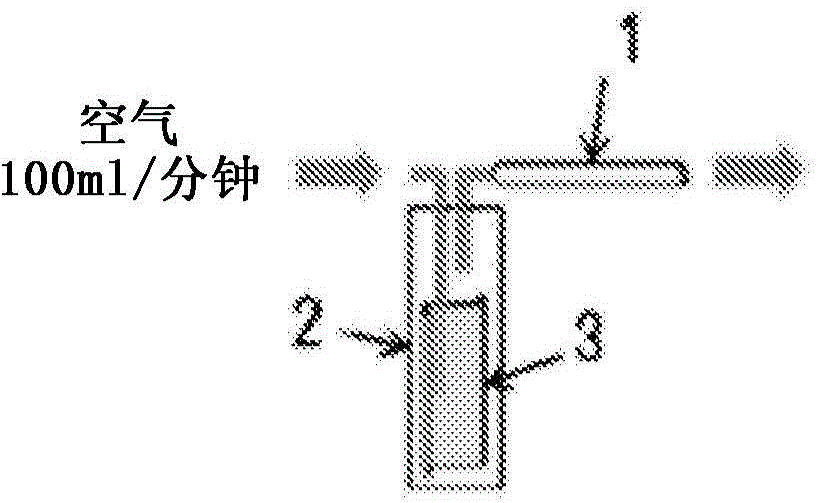

Method used

Image

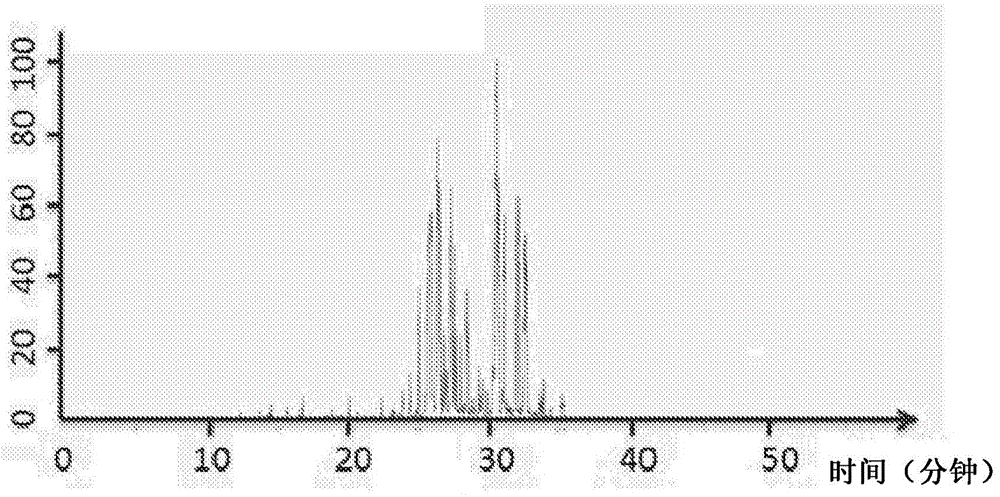

Examples

Embodiment 1

[0209] Put 2.06 moles of 4,4'-MDI into a container with respect to 1 mole of tetramethylene ether glycol with a molecular weight of 3500, use triethylamine as a catalyst, and react at 90°C, and the obtained reaction product is heated under N , N-dimethylacetamide (DMAc) was fully stirred to dissolve it to obtain a solution. Next, a DMAc solution containing ethylenediamine (abbreviated as EDA) as a chain extender is added to the solution in which the reaction product is dissolved, and then a DMAc solution containing diethylamine as an end-capping agent is added, and then, as a stabilizer with A solid content ratio of 1% was added by adding an addition polymer of divinylbenzene and p-cresol ("Metacrol" (registered trademark) 2390 manufactured by DuPont Co., Ltd.) to prepare a polyurethane urea solution PUU-A with a total solid content of 33% by weight. . The resulting solution had a viscosity of about 2800 poise at 40°C. The polymer had an intrinsic viscosity of 0.98 when meas...

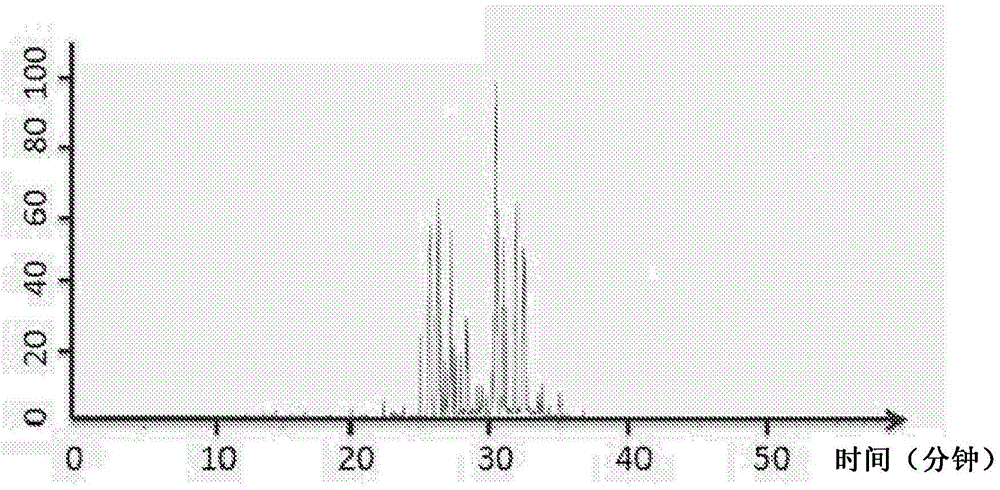

Embodiment 2

[0213] Add 1.70 moles of 4,4'-MDI to 1 mole of tetramethylene ether glycol with a molecular weight of 1800 in a container, react at 90°C, and place the resulting reaction product in N,N-dimethylacetamide (DMAc) was thoroughly stirred to dissolve it to obtain a solution. Next, a DMAc solution containing ethylenediamine (abbreviated as EDA) as a chain extender is added to the solution in which the reaction product is dissolved, and then a DMAc solution containing diethylamine as an end-capping agent is added, and then, as a stabilizer with A solid content ratio of 1% was added by adding an addition polymer of divinylbenzene and p-cresol ("Metacrol" (registered trademark) 2390 manufactured by DuPont Co., Ltd.) to prepare a polyurethane urea solution PUU-B with a total solid content of 30% by weight. . The resulting solution had a viscosity of about 3000 poise at 40°C. The polymer had an intrinsic viscosity of 1.05 when measured at a solution concentration of 0.5 g / 100 mL in DMA...

Embodiment 3

[0217]87.5 moles of tetrahydrofuran after dehydration and 12.5 moles of 3-methyltetrahydrofuran after dehydration are dropped into a reactor with a stirrer, under a blanket of nitrogen at a temperature of 10° C. Mixture) under the existence of carrying out 8 hours polyreaction, with sodium hydroxide aqueous solution, reaction end liquid is carried out neutralization, obtain the copolytetramethylene ether glycol (comprising 12.5 mol % from 3 - Structural unit (a)) of methyltetrahydrofuran, which is used as polyalkylene ether glycol. 4.9 moles of MDI were charged to 1 mole of the copolymerized tetramethylene ether glycol in a container, and reacted at 90° C., and the resulting reaction product was fully dissolved in N,N-dimethylacetamide (DMAc). dissolve. Next, a DMAc solution containing EDA as a chain extender was added to the solution in which the reaction product was dissolved, and then an addition polymer of divinylbenzene and p-cresol (DuPont Co., Ltd. "Metacrol" (registe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| linear density | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com