Phase change composite material capable of simulating filter capsule function and production method and application thereof

A phase-change composite material and a technology of phase-change materials, which are applied in the field of composite materials and their preparations that use gel to simulate the function of traditional popping beads, can solve the problem of poor fragrance retention, poor persistence, and volatilization speed of flavor substances Faster and other issues, to achieve pricing and sales advantages, improve fragrance performance, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

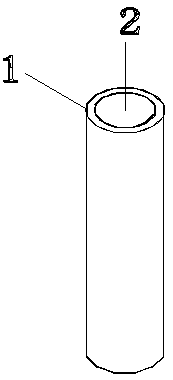

[0042] Such as figure 1 , 4 As shown in 5, this embodiment is a phase change composite material that simulates the function of bursting beads, which is composed of a food-grade PVC hollow hose (1) and a slow-release phase change material (2) wrapped in the hose (1), The overall length is 1 / 3 of the length of the ordinary filter rod, the outer diameter of the hose (1) is 3mm, the inner diameter is 2mm, the radial section of the hose (1) is circular, and there is no internal partition (6). ).

[0043] The preparation method of the phase change material (2) composite material with the function of simulating the bead explosion includes the following steps:

[0044] A. Preparation of phase change materials

[0045] Calculated in parts by weight, mix 80 parts of polyethylene glycol, 10 parts of stearic acid, 2 parts of β cyclodextrin, and 8 parts of propylene glycol, and then mix the above mixture with water in a weight ratio of 18:1 ,At 95 ℃, heat in a water bath for 0.5 hours to dissol...

Embodiment 2

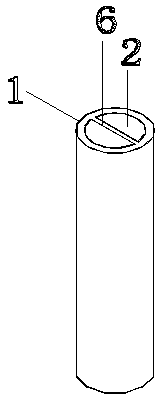

[0051] Such as figure 2 , 4 As shown in 5, this embodiment is a phase change composite material that simulates the function of bursting beads, which is composed of a food-grade PVC hollow hose (1) and a slow-release phase change material (2) wrapped in the hose (1), Its overall length is 2 / 3 of the length of an ordinary filter rod, the outer diameter of the hose (1) is 5mm, and the inner diameter is 3.5mm, the radial section of the hose (1) is circular, the hose (1) ) Internal partition members (6) running through its head and tail are arranged inside to divide the hose (1) into two equal independent spaces. The different spaces contain different phase change materials (2) to realize different phase change materials (2). ) The mixed volatilization automatically adjusts the fragrance.

[0052] The preparation method of the phase change material (2) composite material with the function of simulating the bead explosion includes the following steps:

[0053] A. Preparation of phase c...

Embodiment 3

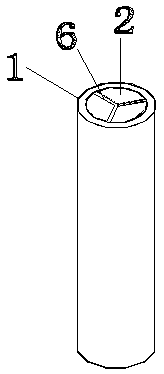

[0060] Such as image 3 , 4 As shown in 5, this embodiment is a phase change composite material that simulates the function of bursting beads, which is composed of a food-grade PVC hollow hose (1) and a slow-release phase change material (2) wrapped in the hose (1), Its overall length is 1 / 2 of the length of an ordinary filter rod, the outer diameter of the hose (1) is 6mm, and the inner diameter is 4mm, the radial section of the hose (1) is circular, the hose (1) Internal partition members (6) running through its head and tail are arranged inside to divide the hose (1) into three equal independent spaces, and different spaces accommodate different phase change materials (2) to realize different phase change materials (2) The mixture evaporates and automatically adjusts the fragrance.

[0061] The preparation method of the phase change material (2) composite material with the function of simulating the bead explosion includes the following steps:

[0062] A. Preparation of phase c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com