A kind of finishing process of moisture-absorbing and sweat-wicking aroma chemical fiber wig

A technology of moisture absorption and perspiration and chemical fiber filaments, which is applied in the field of textile fibers, can solve the problems of wigs, such as difficult odor, low application range, and poor air permeability, etc., achieve good moisture absorption and perspiration performance, solve the problem of sour odor, and enhance the finishing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

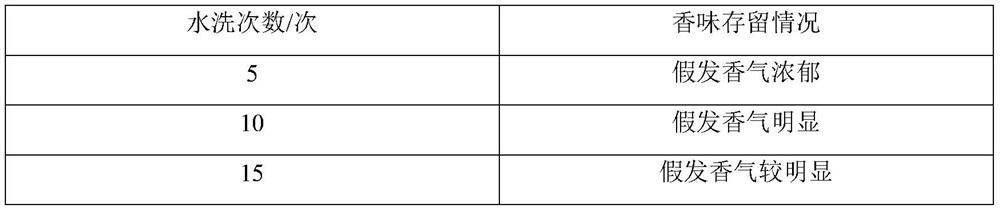

Examples

Embodiment 1

[0042] (1) Weigh 1g of polyester silk wig, wash it thoroughly with water, and let it dry naturally.

[0043] (2) Put the polyester silk wig treated in step (1) into 50ml of emulsifier MOA-7 solution (solution concentration is 5g / L) for further cleaning for 90min, after the end, fully wash with water and dry naturally.

[0044] (3) Hydrophilic finishing of polyester silk wigs with cutinase finishing solution: Soak polyester silk wigs in 100 mL of cutinase finishing solution with a concentration of 50 U / mL at 40 ° C and pH = 6, and add 200 mg of flat Add O and continue stirring for 1h.

[0045] (4) Use the dipping method to carry out moisture absorption and perspiration finishing on polyester silk wigs: at 60°C, dip the polyester silk wigs that have been hydrophilically treated in step (3) in 10g / L ZLJ-2 for 15min, and then dry them at 50°C Dry it for 30min.

[0046] (5) Add 0.2 g of rose essential oil, 1.5 g of gelatin and 0.5 g of emulsifier into a beaker, then add 50 mL of ...

Embodiment 2

[0052] (1) Weigh 2g of polyester silk wig, wash it thoroughly with water, and let it dry naturally.

[0053] (2) Put the polyester silk wig treated in step (1) into 80ml of emulsifier MOA-9 solution (concentration of solution is 3g / L) for further cleaning for 100min. After the end, fully wash with water and dry naturally.

[0054] (3) Hydrophilic finishing of polyester silk wigs with cutinase finishing solution: Soak polyester silk wigs in 100 mL of cutinase finishing solution with a concentration of 100 U / mL at 50 ° C and pH = 7, and add 200 mg of flat Add O and continue stirring for 1h.

[0055] (4) Use the dipping method to carry out moisture absorption and perspiration finishing on polyester silk wigs: at 70°C, dip the polyester silk wigs that have been hydrophilically treated in step (3) in 15g / L ZLJ-6 for 20min, and then dry them at 60°C Dry it for 20min.

[0056] (5) Add 0.4 g of rose essential oil, 1.6 g of gelatin and 0.55 g of emulsifier into a beaker, then add 80 ...

Embodiment 3

[0061] (1) Weigh 5g of polyester wig, wash it thoroughly with water, and let it dry naturally.

[0062] (2) Put the polyester silk wig treated in step (1) into 100ml of emulsifier MOA-15 solution (solution concentration is 8g / L) for further cleaning for 120min, after the end, fully wash with water and dry naturally.

[0063] (3) Hydrophilic finishing of polyester silk wigs with cutinase finishing solution: Soak polyester silk wigs in 100 mL of cutinase finishing solution with a concentration of 150 U / mL at 60 ° C and pH = 8, and add 200 mg of flat Add O and continue stirring for 1h.

[0064] (4) Use the dipping method to carry out moisture absorption and perspiration finishing on polyester silk wigs: at 80°C, immerse the polyester silk wigs that have been hydrophilically treated in step (3) in 20g / L ZLJ-9 for 25min, and then dry them at 70°C Dry it for 15 minutes.

[0065] (5) Add 0.6 g of rose essential oil, 1.7 g of gelatin and 0.6 g of emulsifier into a beaker, then add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com