Quenching method of die and manufacture method of die

A mold and mold heating technology, applied in the direction of manufacturing tools, heat treatment equipment, furnaces, etc., can solve problems such as easy cracks, achieve the effect of suppressing cracks and maintaining toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] Experimental points

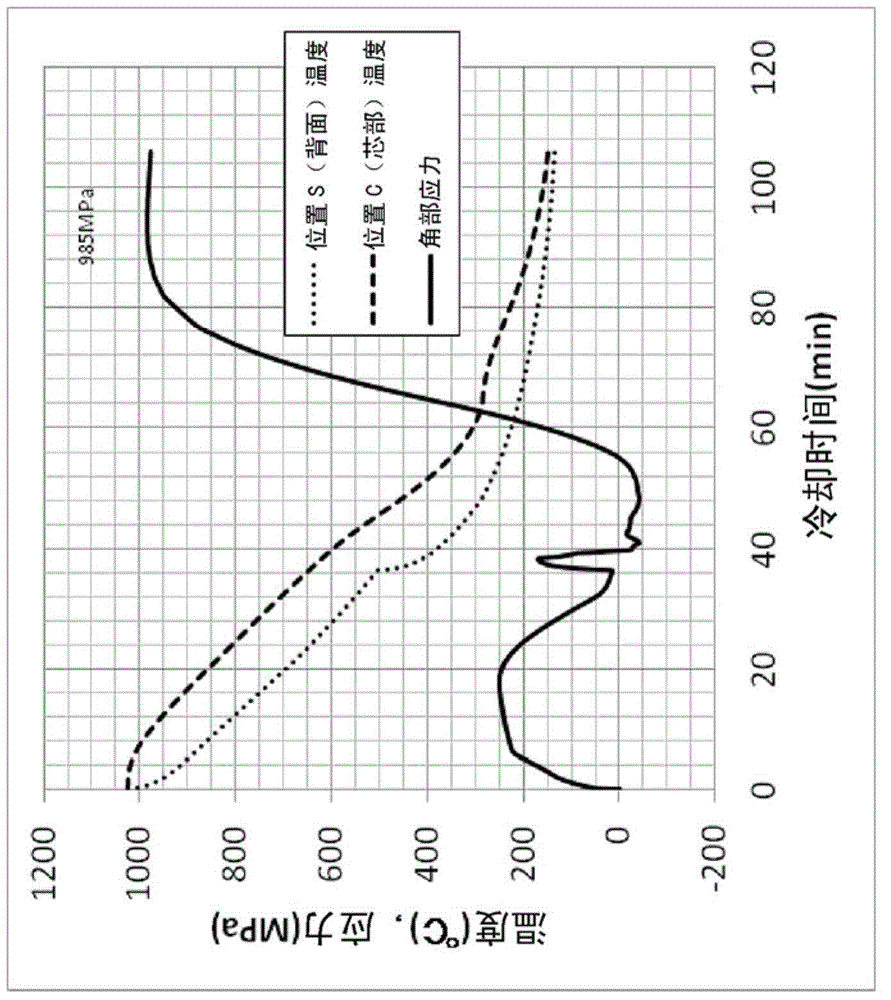

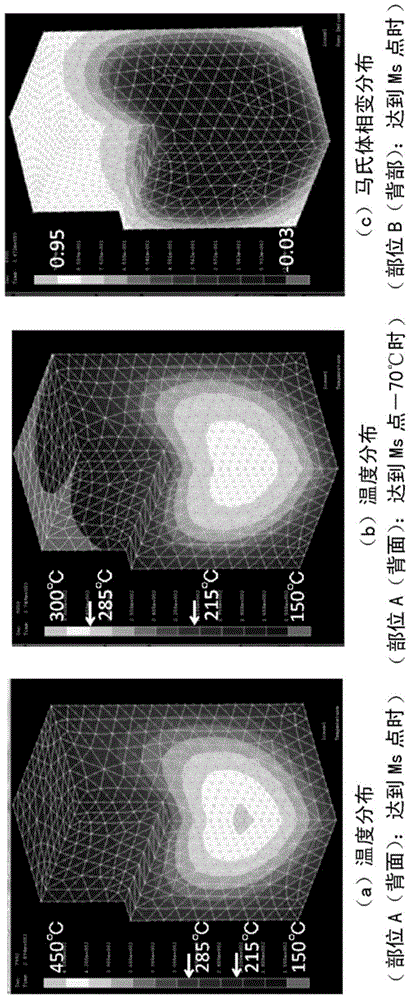

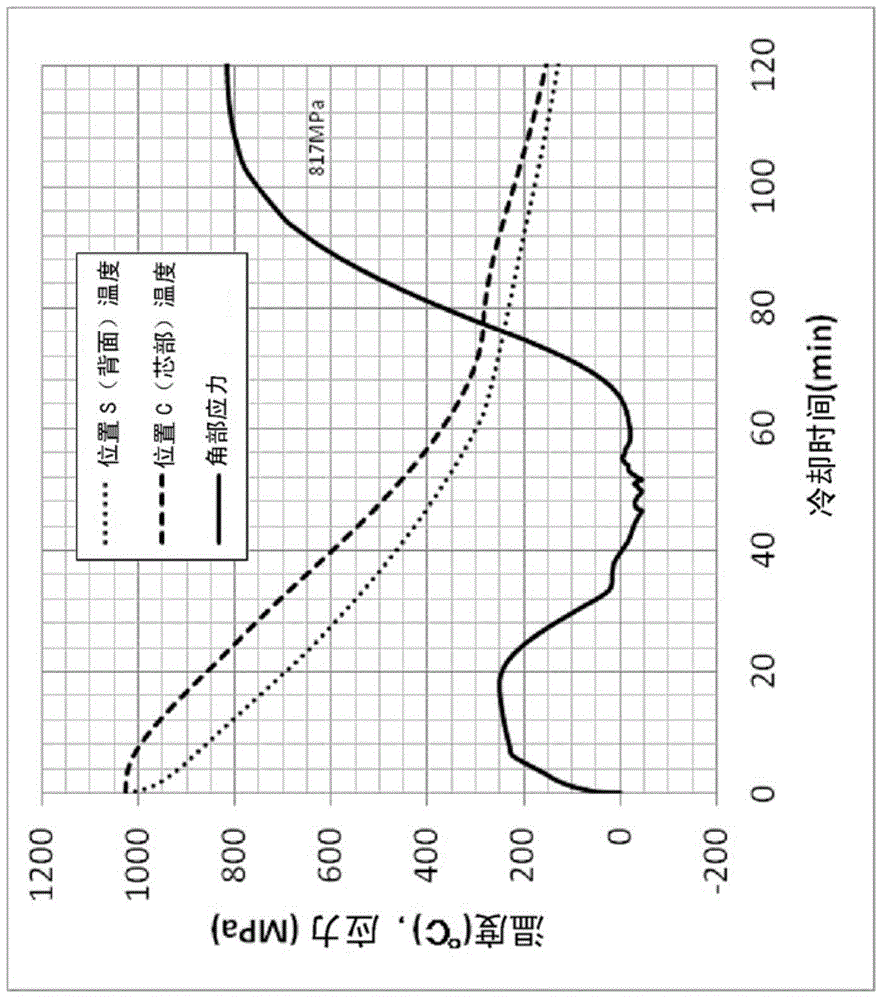

[0041] A 300mm×300mm×300mm square is made of hot-worked tool steel, which is an improved material of JIS-SKD61 in Japan, as a raw material. The entire surface of the block is milled. The martensitic transformation point (Ms point) of this raw material was 285°C. Next, this block was processed to form a concave groove with a depth of 100mm and a width of 50mm corresponding to the product shape surface of the mold, thereby producing a Figure 7 samples for quenching. The corner portion of the groove bottom was processed such that R (radius of curvature) of the corner portion was 1 mmR on one side and 3 mmR on the opposite side. In addition, from the center of the bottom of the groove toward the back of the sample, there are also positions C (that is, the core of the sample) with a depth of 90 mm and positions S (that is, the actual back of the sample) with a depth of 195 mm. central location) forms the insertion hole for the thermocouple that a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com