Method of extracting lignins different in molecular weight from bamboo pulping black liquor

A technology for pulping black liquor and lignin, which is applied in the field of lignin extraction with different molecular weights, can solve the problems of low separation efficiency and complex lignin fractionation process, and achieve large membrane flux, strong industrial applicability, and slow attenuation speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Put 1000g of dry bamboo (sliced to 10×20mm) into a 15L vertical electric heating cooking pot, add NaOH and Na 2 S, the degree of sulfide is 20%, the amount of alkali is 10% (referring to NaOH+Na 2 S content, as Na 2 O meter) cooking liquor. After idling at 80 °C for 20 min, the temperature was raised to 160 °C at a rate of 2 °C / min and kept for 1 h. After the reaction is finished, filter the cooking material with a cloth bag to obtain the black liquor of bamboo pulping. The main components of the black liquor are partially degraded lignin, monosaccharides and chemicals, with a solid content of 12.34% and a viscosity of 12.48cps.

Embodiment 2

[0024] A method for fractionating different molecular weight lignin from bamboo pulping black liquor, the steps are as follows

[0025] 1) Bamboo pulping black liquor (prepared in Example 1) was filtered with a Buchner funnel to remove fine fibers and impurities, and hydrochloric acid was added to the filtrate to adjust the pH value to 1.5-2.0 to precipitate lignin;

[0026] 2) The precipitated lignin was dried in an oven at 60°C, and 5 g of the precipitated lignin was dissolved in 40 mL of 90 % (v / v) acetic acid solution to form a lignin acetic acid solution. The lignin in the solution The solids concentration was 12.50 % (w / v).

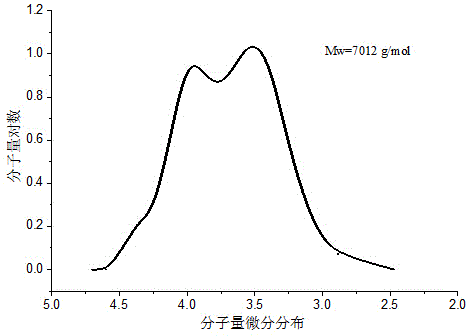

[0027] 3) Use an ultrafiltration centrifuge tube with a molecular weight cut-off of 5000 Da to ultrafilter the lignin acetic acid solution at 4000 rpm for 30 minutes to obtain the retentate F1 and ultrafiltrate;

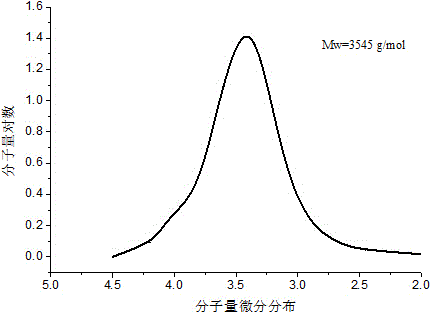

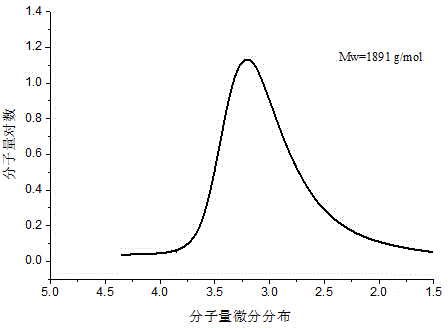

[0028] 4) The above ultrafiltrate was ultrafiltered with an ultrafiltration centrifuge tube with a molecular weight cut-off of 3000 Da a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com