Two-way hydraulic machine

A hydraulic press and two-way technology, applied in the field of hydraulic presses, can solve the problems of small stroke, large pressing area, easy damage to hydraulic cylinder, etc., and achieve the effects of long service life, large pressing area and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

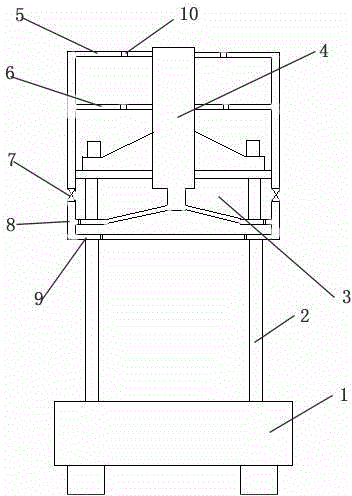

[0010] like figure 1 As shown, the present invention provides a kind of two-way hydraulic machine, comprises machine base 1, column 2, frame 3 and hydraulic oil cylinder 4, and described hydraulic oil cylinder 4 is fixed on the frame 3, and described frame 1 is made of four columns 2 Fixed with the machine base 1, the upper part of the hydraulic cylinder 4 is symmetrically connected to the upper oil pipe 5, and the lower part of the hydraulic cylinder is connected to the lower oil pipe 6 symmetrically. 6 are connected by an electromagnetic reversing valve 7, and the left and right positions below the electromagnetic reversing valve 7 are respectively provided with an oil inlet pipe 8 and an oil return pipe 9, and the oil inlet pipe 8 and the oil return pipe 9 are connected with the hydraulic cylinder 4.

[0011] As a further improvement, a filter screen 10 is provided at each oil pipe to filter out impurities in the oil, so that the service life of the hydraulic machine is lon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com