Manufacturing method of a soft canned seasoned and instant ictalurus punctatus

A technology for channel catfish and its preparation method, which is applied in food preparation, food drying, food science, etc., can solve problems such as the single processing form of channel catfish, affecting the market demand for frozen catfish fillets, and restricting the development of catfish-related products, etc. To achieve the effect of convenient and diverse eating methods, prolonging the sales time and enriching the market

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

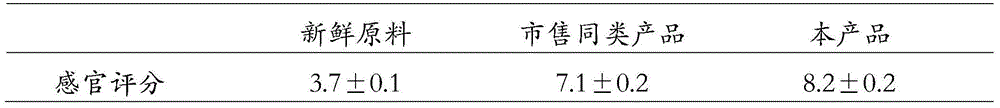

Examples

Embodiment 1

[0025] After thawing fresh fish or frozen catfish, remove the head, tail, viscera, wash, evenly divide and cut into 4cm×3cm×1.5cm fish pieces; put the divided fish pieces into the mixed deodorizing agent Medium deodorization, the material-liquid ratio of fish block and deodorization agent is 1:3, the temperature is 4°C, the deodorization time is 2h, the mixed deodorization agent is calculated as 100g: 1.5 black tea is brewed with 70g boiling water at room temperature for 0.5h. After cooling, add 4g of table salt, 1g of sodium bicarbonate, 3g of cooking wine, and make up the rest with cold water; wash off the salt on the surface of the fish pieces with running water for 3 minutes, drain them, and place them in a hot air drying box for blast drying at 50°C for 3 hours. until the moisture content is about 65%; fry the pre-dried fish pieces in oil at 120°C for 5 minutes, remove immediately and fry in oil at 200°C for 2 minutes, until the surface of the fish pieces is golden yellow ...

Embodiment 2

[0029]After thawing fresh fish or frozen catfish, remove the head, tail, viscera, wash, evenly divide and cut into 4cm×3cm×1.5cm fish pieces; put the divided fish pieces into the mixed deodorizing agent For deodorization, the material-liquid ratio of fish block and deodorizer is 1:3, the temperature is 7°C, the deodorization time is 2h, the mixed deodorizer is calculated as 100g: 2g black tea is brewed with 70g boiling water for 0.5h at room temperature, and the After cooling, add 5g of table salt, 2g of sodium bicarbonate, 2g of cooking wine, and make up the rest with cold water; wash off the salt on the surface of the fish pieces with running water for 4 minutes, drain them, and put them in a hot air drying oven for blast drying at 55°C for 2.5 hours , until the moisture content is about 67%; fry the pre-dried fish pieces in oil at a temperature of 130°C for 4 minutes, immediately remove them and fry them in oil at a temperature of 180°C for 3 minutes, until the surface of th...

Embodiment 3

[0033] After thawing fresh fish or frozen catfish, remove the head, tail, viscera, wash, evenly divide and cut into 4cm×3cm×1.5cm fish pieces; put the divided fish pieces into the mixed deodorizing agent For medium deodorization, the mass-to-liquid ratio of fish pieces and deodorizing agent is 1:3, the temperature is 10°C, the deodorizing time is 2 hours, and the mixed deodorizing agent is calculated as 100g: 3g of black tea is brewed with 70g of boiling water at room temperature for 0.5h. After cooling, add 6g of table salt, 3g of sodium bicarbonate, 2g of cooking wine, and make up the rest with cold water; wash off the salt on the surface of the fish pieces with running water for 5 minutes, drain them, and place them in a hot air drying oven to dry them with air at 55°C for 2.5 h, until the moisture content is about 70%; fry the pre-dried fish pieces in oil at a temperature of 140°C for 3 minutes, immediately take them out and fry them in oil at a temperature of 180°C for 3 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com