Chitosan-Nisin core-shell microspheres and preparation method and application thereof

A technology of chitosan and chitosan solution, which is applied in the direction of preserving meat/fish with chemicals, can solve the problems of chemical preservative residue, high temperature setting requirements, and large investment in supporting facilities, etc., to achieve enhanced antibacterial activity, Effect of maintaining nutritional and sensory properties, good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

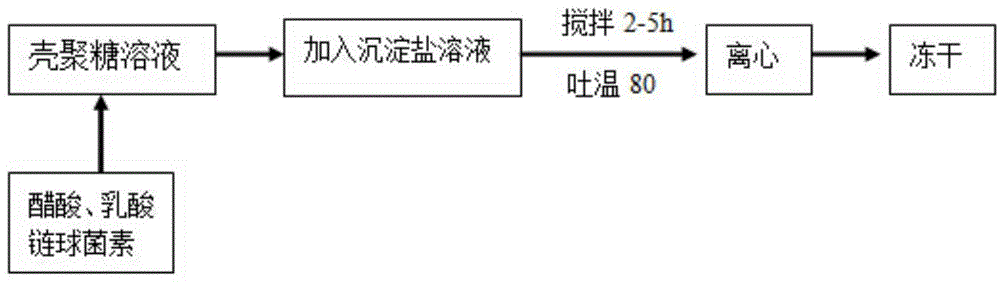

[0023] Example 1: This example prepares chitosan-Nisin core-shell microspheres.

[0024] Accurately weigh 1.000g of chitosan and dissolve in 900ml of pure water, add 9ml of glacial acetic acid to fully dissolve, stir, and sonicate for 10min. Accurately add 1.000g of Nisin to the upward solution, and after mixing evenly, add 100ml of 0.5M trisodium citrate solution with an infusion pump at a speed of 0.5ml / min. Add 5ml of Tween 80 as a non-ionic stabilizer, and stir for 2h under a magnetic stirrer. The resulting suspension was centrifuged at 6000 r / min at 4° C. for 10 minutes, the supernatant was discarded, and the resulting precipitate was placed in a -80° C. refrigerator and freeze-dried to obtain chitosan-embedded Nisin particles.

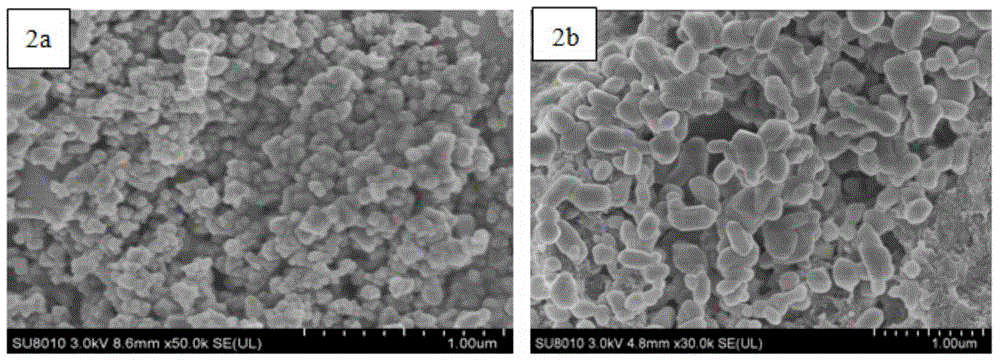

[0025] Test result: measure the content of Nisin in the supernatant that step 2 discards with high performance liquid phase method, obtain the embedding rate of Nisin 58%; By laser particle size analyzer, record the average particle diameter of ...

Embodiment 2

[0027] Example 2: This example prepares chitosan-Nisin core-shell microspheres.

[0028] Accurately weigh 3.000g of chitosan and dissolve in 900ml of pure water, add 18ml of glacial acetic acid to fully dissolve, stir, and sonicate for 10min. Accurately add 1.500g Nisin to the upward solution, and after mixing evenly, add 0.5M sodium sulfate solution at a rate of 2ml / min with an infusion pump. Then add 10ml Tween 80 as a non-ionic stabilizer and stir for 3.5h under a magnetic stirrer. The resulting suspension was centrifuged at 8000 r / min at 4° C. for 10 minutes, the supernatant was discarded, and the resulting precipitate was placed in a -80° C. refrigerator and freeze-dried to obtain chitosan-embedded Nisin particles.

[0029] Test results: The inclusion compound prepared by this formula has a Nisin embedding rate of 62% and an average particle size of 930±45.8nm.

[0030] Referring to the usage limit of Nisin in food additives and other factors, 0.75 g of the core-shell m...

Embodiment 3

[0031] Example 3: This example prepares chitosan-Nisin core-shell microspheres.

[0032] Accurately weigh 3.000g of chitosan and dissolve in 900ml of pure water, add 13.5ml of glacial acetic acid to fully dissolve, stir, and sonicate for 10min. Accurately add 1.000g of Nisin to the upward solution, and after mixing evenly, add 100ml of 0.5M trisodium citrate solution at a rate of 6ml / min with an infusion pump. Then 8ml of Tween 80 was added as a non-ionic stabilizer. Stir for 5 h under a magnetic stirrer. The resulting suspension was centrifuged at 8000 r / min at 4° C. for 10 minutes, the supernatant was discarded, and the resulting precipitate was placed in a -80° C. refrigerator and freeze-dried to obtain chitosan-embedded Nisin.

[0033] Test results: The inclusion compound prepared by this formula has a Nisin embedding rate of 61% and an average particle size of 677±35.6nm.

[0034] Referring to the usage limit of Nisin in food additives and other factors, 1.0 g of the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com