A separate fully automatic spray dry-wet cycle test device

A dry-wet cycle and test device technology, applied in measurement devices, analytical materials, material inspection products, etc., can solve the problems of large volume, large workload, low accuracy, etc., to broaden the scope of application, high work efficiency, and stability. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiments of the present invention will be further described below in conjunction with the drawings.

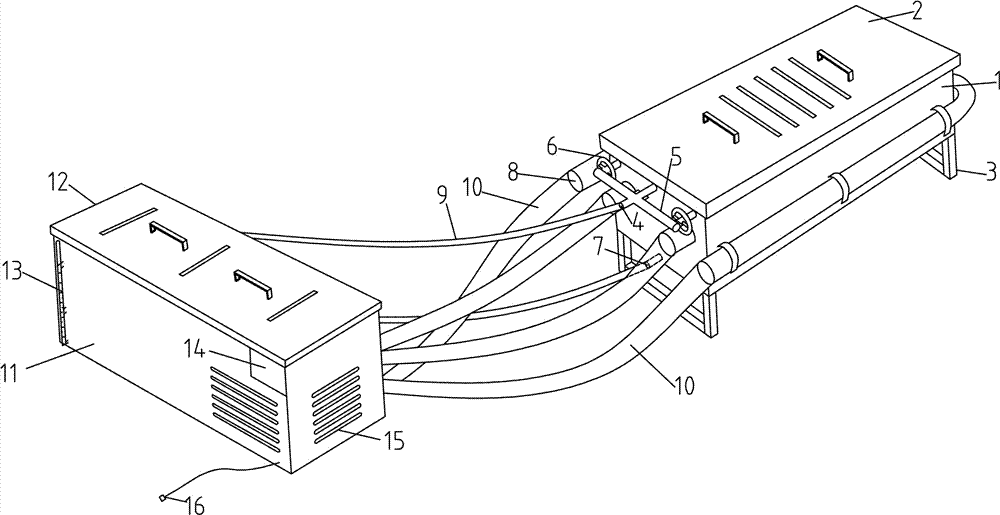

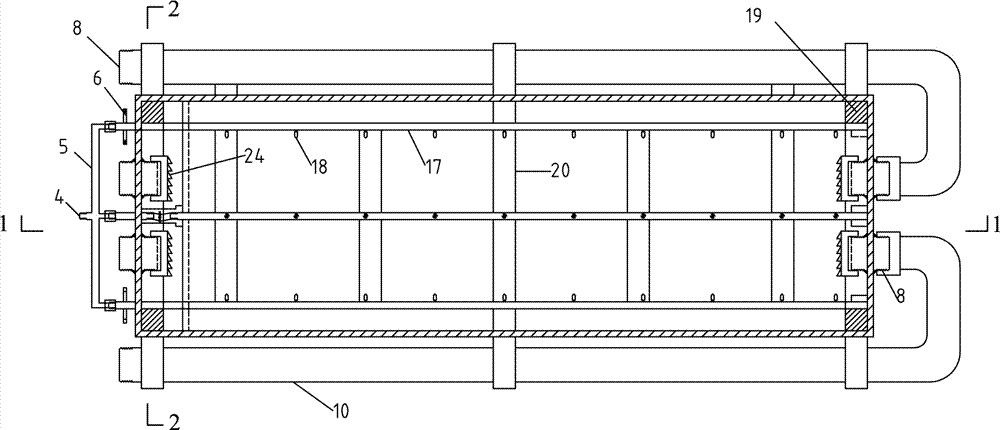

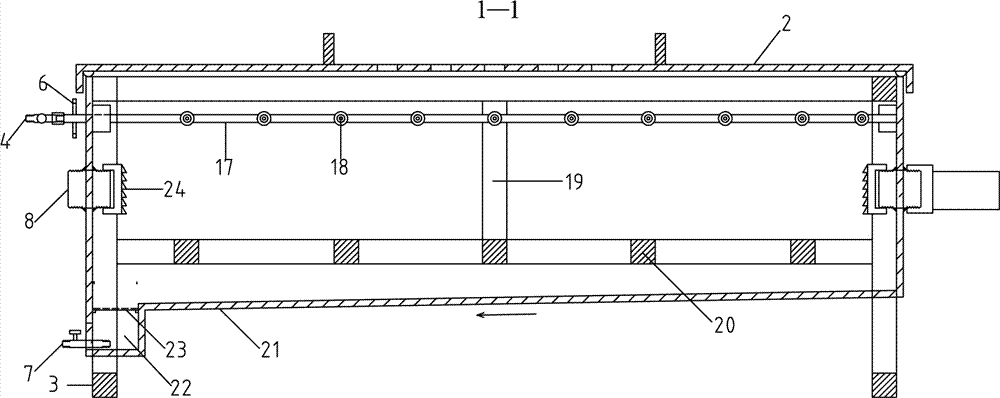

[0031] See Figure 1-9 , A separate automatic spray dry-wet cycle test device, which includes a spray box 1, the spray box 1 and the water and air control box 11 are connected by a water pipe 9 and a wind pipe 10, and the water and air control box 11 has a water outlet 33. The water inlet 34 and the drain 35, the spray box 1 has a spray box water inlet 4 and a spray box outlet 7, and the water outlet 33 of the water and air control box 11 is connected with the spray box water inlet 4, spraying The water outlet 7 of the box is connected with the water inlet 34 of the water and air control box 11; the hot air outlet 42 of the water and air control box 11 is connected with the air pipe interface 8 of the spray box 1; the upper part of the spray box 1 is provided with a spray box cover 2. The spray box cover 2 has a handle and an air inlet. The upper part of the water a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com