Paenibacillus damxungensis sp.nov. CGMCC No.8333 chymosin and preparation method

A technology of Paenibacillus and Bacillus, which is applied in the field of Paenibacillus CGMCC No.8333 chymosin and its preparation, can solve the problems of difficult to meet large-scale industrial production, low recovery rate of chymosin, complicated operation process, etc., and achieve convenient Industrialized operation, simple and effective operation, and the effect of simplifying the preparation process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Paenibacillus BD3526 was inoculated in TYC medium and cultured at 30°C for 20 hours to obtain seed liquid. The TYC medium was composed of the following components: casein peptone 15g / L, sucrose 50g / L, yeast extract 5.0g / L, L-cystine 0.2g / L, sodium acetate 20g / L, Na 2 SO 4 0.1g / L, NaCl 1g / L, NaCl 2 HPO 4 12H 2 O 2g / L, NaHCO 3 2g / L, agar 15g / L, and the balance is water.

[0042] Inoculate 4% (v / v) of the seed liquid into a 250mL Erlenmeyer flask containing 50mL of bran medium, ferment and cultivate for 72 hours at 30°C with a shaker shaking speed of 180r / min to obtain BD3526 fermentation broth. The composition of the bran medium is: the mass percentage of wheat bran is 2%, and the balance is water.

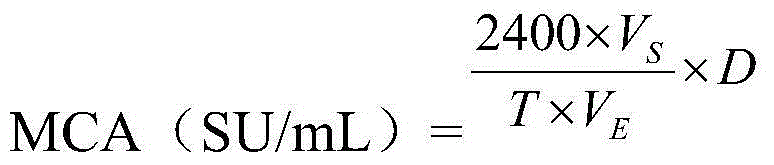

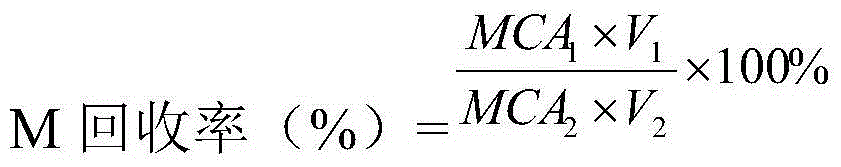

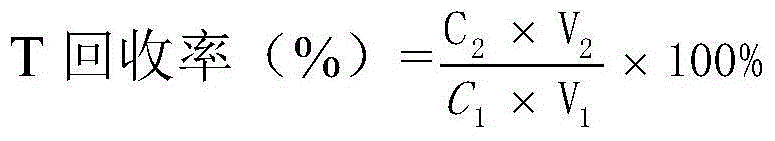

[0043] Centrifuge the BD3526 fermentation broth at 4°C and 15,000g for 15 minutes, collect the fermentation supernatant Q1, dilute the fermentation supernatant 3 times with 0.02mol / L, pH 7.0 PBS solution, and measure the fermentation supernatant Q1 curd Enzyme activi...

Embodiment 2

[0050] Paenibacillus BD3526 was inoculated in TYC medium and cultured at 30°C for 20 hours to obtain seed liquid. The TYC medium was composed of the following components: tryptone 15g / L, sucrose 50g / L, yeast extract 5.0g / L, L-cystine 0.2g / L, sodium acetate 20g / L, Na 2 SO 4 0.1g / L, NaCl 1g / L, NaCl 2 HPO 4 12H 2 O 2g / L, NaHCO 3 2g / L, agar 20g / L, and the balance is water.

[0051] Inoculate 2% (v / v) of the seed liquid into a 250mL Erlenmeyer flask containing 50mL of bran medium, ferment and cultivate for 48 hours at 28°C with a shaker at a shaking speed of 300r / min to obtain BD3526 fermentation broth. The composition of the bran medium is: the mass percentage of wheat bran is 1%, and the balance is water.

[0052] Centrifuge the BD3526 fermentation broth at 4°C and 15,000g for 15 minutes, collect the fermentation supernatant Q1, dilute the fermentation supernatant 3 times with 0.02mol / L, pH 7.0 PBS solution, and measure the fermentation supernatant Q1 curd Enzyme activit...

Embodiment 3

[0058] Paenibacillus BD3526 was inoculated in TYC medium and cultured at 28°C for 20 hours to obtain seed liquid. The TYC medium was composed of the following components: casein peptone 15g / L, sucrose 50g / L, yeast extract 5.0g / L, L-cystine 0.2g / L, sodium acetate 20g / L, Na 2 SO 4 0.1g / L, NaCl 1g / L, NaCl 2 HPO 412H 2 O 2g / L, NaHCO 3 2g / L, agar 15g / L, and the balance is water.

[0059] Inoculate 4% (v / v) of the seed liquid into a 250mL Erlenmeyer flask containing 50mL of bran medium, ferment and cultivate for 72 hours at 30°C with a shaker shaking speed of 180r / min to obtain BD3526 fermentation broth. The composition of the bran medium is as follows: the mass percentage of wheat bran is 5%, and the balance is water.

[0060] Centrifuge the BD3526 fermentation broth at 4°C and 15,000g for 15 minutes, collect the fermentation supernatant Q1, dilute the fermentation supernatant 3 times with 0.02mol / L, pH 7.0 PBS solution, and measure the fermentation supernatant Q1 curd Enz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com