Water-based metallic basic coating composition

A basic coating and composition technology, applied in the field of water-based metal basic coating compositions, can solve the problems of uneven metal coating, reduce drying time, etc., and achieve the effects of excellent smoothness, excellent sparkle, and excellent physical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

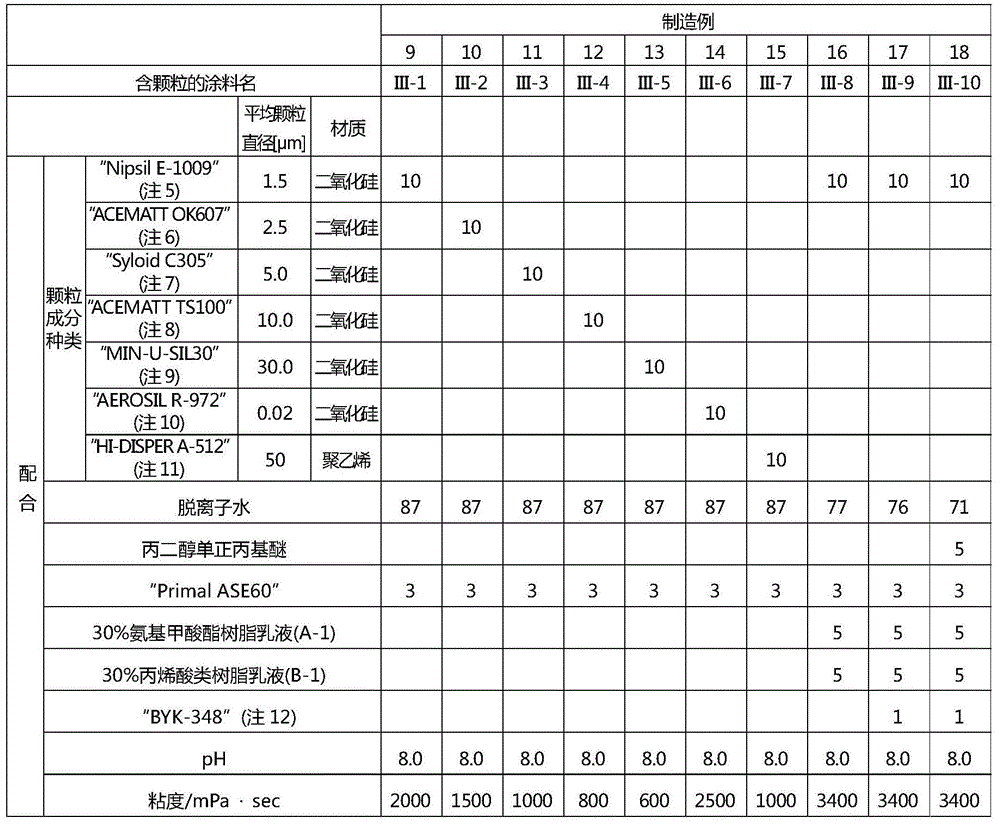

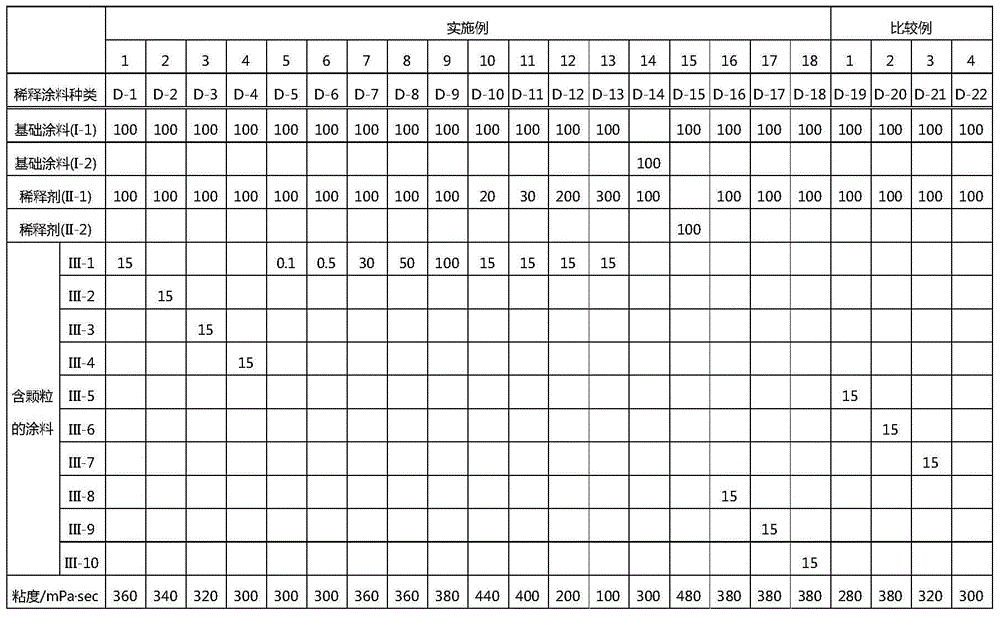

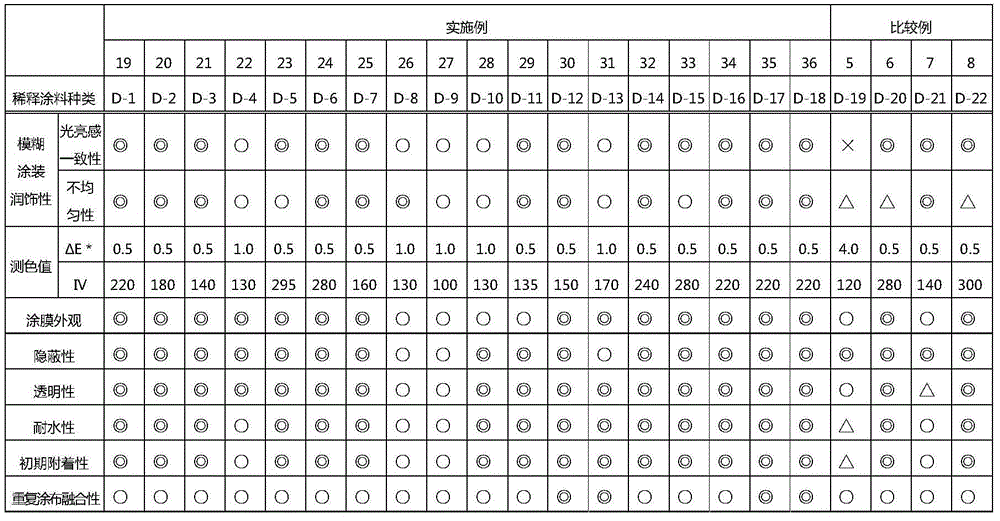

[0148] Hereafter, although an Example demonstrates this invention more concretely, this invention is not limited to these Examples. In addition, "parts" and "%" in the following examples represent "parts by mass" and "% by mass", respectively.

[0149]

manufacture example 1

[0151] Into the reaction vessel, add 115.5 parts of polybutylene adipate with a number average molecular weight of 2000, 115.5 parts of polycaprolactone diol with a number average molecular weight of 2000, 23.2 parts of dimethylol propionic acid, 1,4-butyl 14.5 parts of diol and 120.1 parts of isophorone diisocyanate were reacted at 85° C. for 7 hours in a nitrogen stream with stirring to obtain a prepolymer having an NCO content of 4.0%. Next, the prepolymer was cooled to 50°C, 165 parts of acetone was added and dissolved uniformly, then 15.7 parts of triethylamine was added under stirring, and 600 parts of deionized water was added while keeping the temperature below 50°C, and the obtained water The dispersion was kept at 50°C for 2 hours to complete the water extension reaction, and then the acetone was distilled off under reduced pressure below 70°C, and the pH was adjusted to 8.0 with triethylamine and deionized water, and the acid value of the solid was obtained. A ureth...

manufacture example 2

[0154] 100 parts of deionized water, 2.5 parts of "Newcol 707SF" (manufactured by Nippon Emulsifier Co., Ltd., an anionic emulsifier with a polyoxyethylene chain, solid content of 30%) and a monomer mixture (9 parts of styrene, 1 part of 39 parts of n-butyl acrylate, 40 parts of 2-ethylhexyl acrylate, 10 parts of 2-hydroxyethyl acrylate, 1 part of methacrylic acid, and 1 part of allyl methacrylate), using nitrogen gas flow Stirring and mixing were performed, and 3 parts of 3% ammonium persulfate aqueous solution were added at 60°C. Next, the temperature was raised to 80°C, and a pre-emulsion consisting of the remaining 99 parts of the aforementioned monomer mixture, 2.5 parts of "Newcol707SF", 4 parts of 3% ammonium persulfate, and 100 parts of deionized water was added to the reaction using a quantitative pump for 4 hours. The container was matured for 1 hour after the addition was completed. Thereafter, 33 parts of deionized water were added, adjusted to pH 7.5 by using dim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com