Waterborne polyurethane waterproof coating and production process thereof

A water-based polyurethane and waterproof coating technology, applied in the field of coatings, can solve the problems of high environmental and human hazards, harmful to human body, and coatings, and achieve the effects of no environmental pollution, good aging resistance, weather resistance and good waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

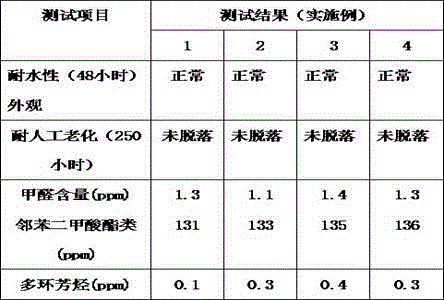

Examples

Embodiment 1

[0023] The water-based polyurethane waterproof coating of the present invention comprises the following components in parts by weight: 25 parts of water-based polyurethane resin, 20 parts of ethylene glycol ethyl ether acetate, 1 part of polyglycol, 8 parts of diethylene glycol, dihydroxypropionic acid 7 parts, 4 parts of nano silicon dioxide, 1 part of tributyl phosphate, 15 parts of nano calcium carbonate, 6 parts of polydimethylsiloxane, 3 parts of high carbon alcohol, 4 parts of alcohol ester twelve, 40 parts of deionized water share.

[0024] The processing steps of preparation are as follows:

[0025] Mix the above ethylene glycol ether acetate with deionized water, heat at 60°C for 20 minutes, and cool to room temperature; add polyglycol, diethylene glycol, dihydroxypropionic acid, nano-silica, tributyl phosphate , stirring and dispersing at 600 rpm for 15 minutes; adjust the pH value to 7, add the remaining raw materials except the water-based polyurethane resin, stir...

Embodiment 2

[0027] The water-based polyurethane waterproof coating of the present invention comprises the following components in parts by weight: 35 parts of water-based polyurethane resin, 10 parts of ethylene glycol ethyl ether acetate, 10 parts of polyglycol, 2 parts of diethylene glycol, dihydroxypropionic acid 3 parts, 9 parts of nano-silica, 5 parts of tributyl phosphate, 5 parts of nano-talc powder, 2 parts of polymethylphenylsiloxane, 8 parts of dimethyl silicone oil, 12 parts of alcohol ester twelve, deionized 30 parts of water.

[0028] The processing steps of preparation are as follows:

[0029] Mix the above-mentioned ethylene glycol ethyl ether acetate with deionized water, heat at 80°C for 40 minutes, and cool to room temperature; add polyglycol, diethylene glycol, dihydroxypropionic acid, nano-silica, tributyl phosphate , stirring and dispersing at 600 rpm for 25 minutes; adjust the pH value to 8, add the remaining raw materials except the water-based polyurethane resin, ...

Embodiment 3

[0031] The water-based polyurethane waterproof coating of the present invention comprises the following components in parts by weight: 30 parts of water-based polyurethane resin, 25 parts of ethylene glycol ethyl ether acetate, 6 parts of polyglycol, 5 parts of diethylene glycol, dihydroxypropionic acid 5 parts, 6 parts of nano silicon dioxide, 3 parts of tributyl phosphate, 10 parts of nano mica powder, 4 parts of polyether modified organosiloxane, 6 parts of emulsified silicone oil, 8 parts of alcohol ester twelve, 35 parts of deionized water share.

[0032] The processing steps of preparation are as follows:

[0033] Mix the above-mentioned ethylene glycol ethyl ether acetate with deionized water, heat at 70°C for 30 minutes, and cool to room temperature; add polyglycol, diethylene glycol, dihydroxypropionic acid, nano-silica, tributyl phosphate , stirring and dispersing at 800 rpm for 20 minutes; adjust the pH value to 7, add the remaining raw materials except the water-b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com