Special antimicrobial mould-proof low-odor regenerative polypropylene modified material for automobile instrument desk and preparation method thereof

A technology for regenerated polypropylene, antibacterial and mildew-proof, applied in the field of polymer materials, can solve the problems of carrying microorganisms and strong odor, and achieve the effect of improving the environment, improving the utilization rate and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

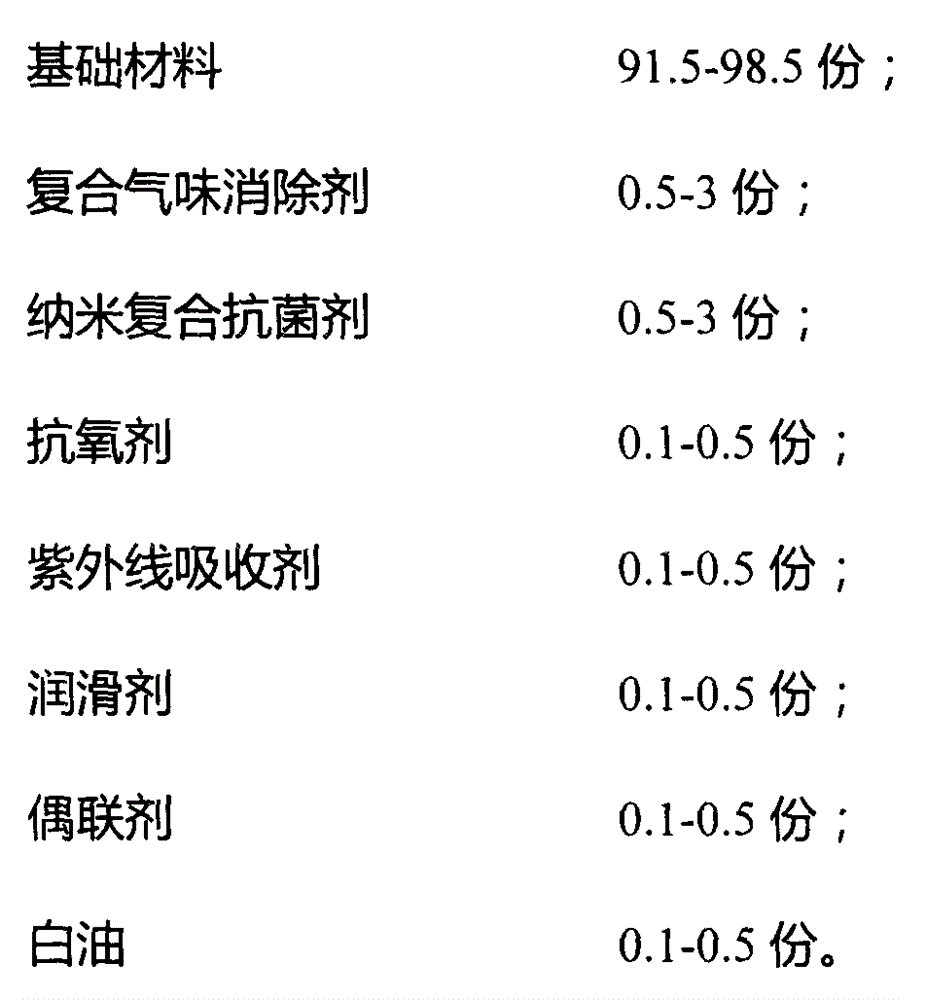

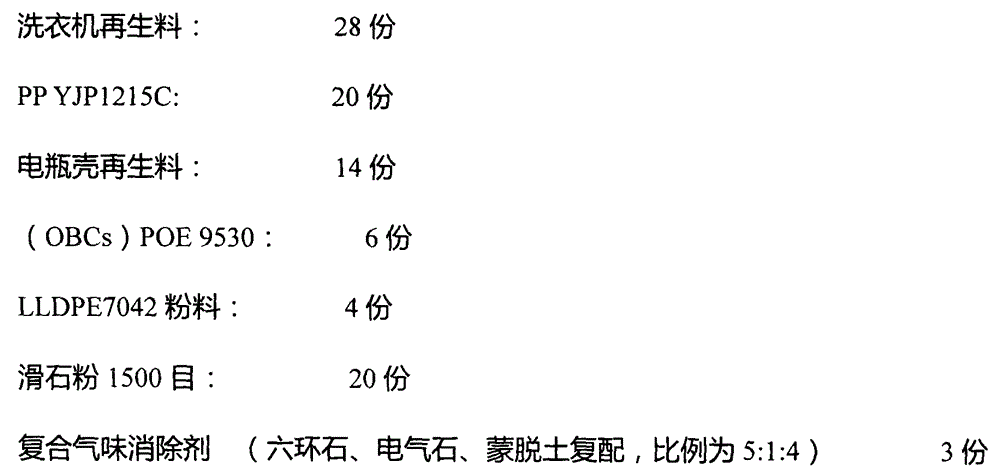

[0029] The matching ratio is as follows:

[0030]

[0031]

[0032] The preparation method is as follows:

[0033] (1) Color separation and classification of the above-mentioned recycled polypropylene materials, clean water, blow label, filter metal

[0034] (2) Premix the nano composite antibacterial agent, composite odor eliminator, lubricant, and PE powder at low speed for 3 minutes, and then mix at high speed for 30 seconds.

[0035] (3) Blend the recycled polypropylene material and the remaining formula material with the pre-mixed material in step 2 uniformly. Add into twin screw extruder, melt extrusion granulation.

[0036] The process parameters of the twin screw extruder are:

[0037] Zone 1 170-190℃; Zone 2 180-190℃; Zone 3 180-200℃; Zone 4 190-210℃; Zone 5 190-210℃; Zone 6 190-210℃; Zone 7 190-210℃; Zone 180-200, nine zone 180-200℃; head 190-200℃; screw speed control at 200-500r / min, twin screw length to diameter ratio is 32-40.

[0038] (4) The particles made in step (3) are...

Embodiment 2

[0041]

[0042]

[0043] The preparation method is the same as in Example 1.

Embodiment 3

[0045]

[0046]

[0047] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com