Molten aluminum quantified feeding system

A technology for feeding soup and molten aluminum, applied in the field of quantitative feeding system of molten aluminum, can solve the problems of large amount of compressed air, easy blockage, and increase the energy input of manufacturers, so as to reduce the formation of oxide slag, reduce the chance of contact, Significant energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

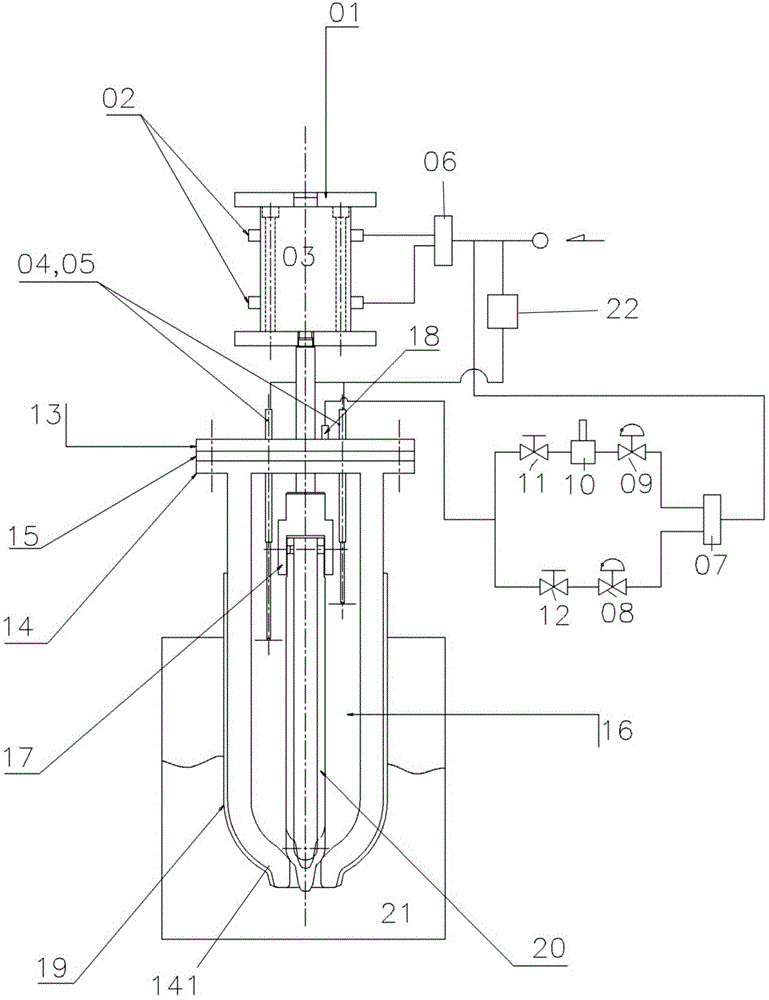

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0023] Such as figure 1 The aluminum liquid quantitative dispensing system shown includes a stopper rod 20, an outer cylinder 14, a first probe 4, a second probe 5, a driving mechanism for driving the stopper rod 20 to rotate and vertically move up and down, and a In the vacuum or pressurized air pressure generating device, the lower end of the outer cylinder 14 is set as the beak opening 141; the stopper rod 20 is placed in the outer cylinder 14, and the lower end of the stopper rod 20 is inserted into the beak opening 141, and the beak opening 141 is connected with the beak opening. The opening 141 is sealed and slidably fitted, and protrudes downward from the beak opening 141. The upper end of the stopper rod 20 seals upwards and passes through the outer cylinder 14 and is connected with the driving mechanism; the air pressure gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com