Pressure glue supply system of cigarette making machine

A cigarette machine and pressure technology, which is applied to tobacco, cigarette manufacturing, and devices for coating liquid on the surface, etc., can solve the problems of low self-gravity glue supply pressure, easy clogging of product quality, hidden dangers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

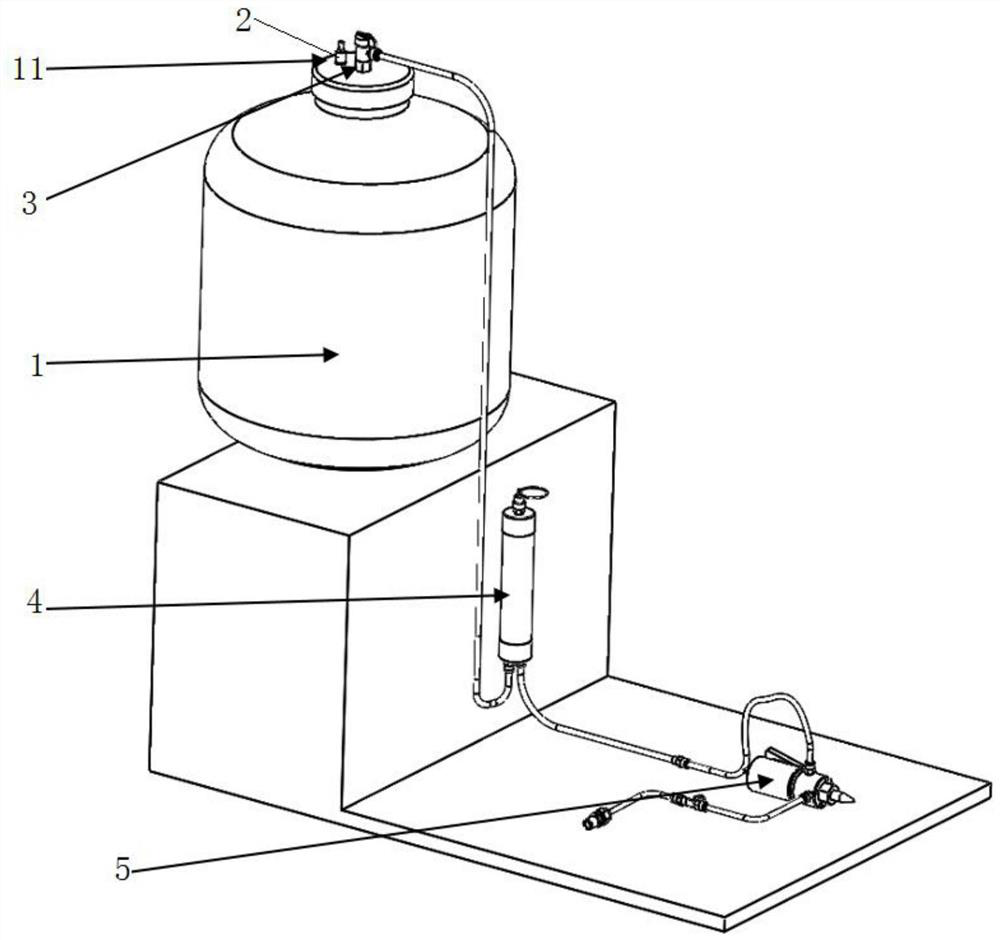

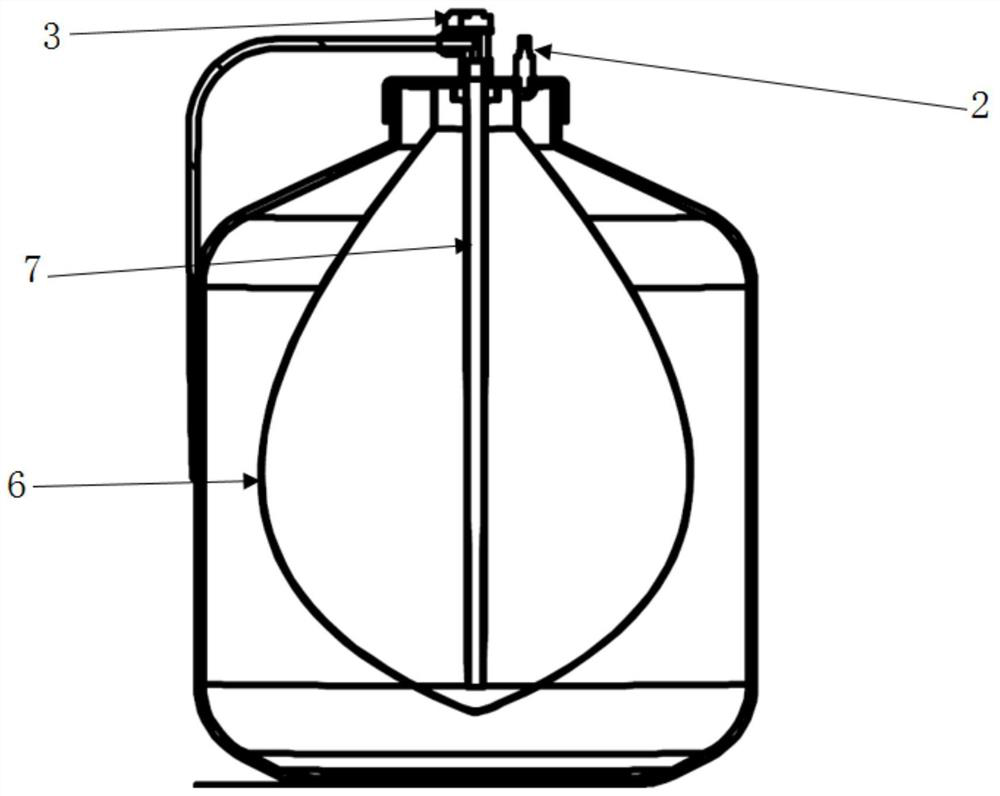

[0019] Such as figure 1 and figure 2 As shown, the present application provides a pressure glue supply system for a cigarette machine, which consists of a glue storage device, an exhaust device 4 , an air supply device and a glue spray nozzle 5 . The air supply device includes at least an air compressor and an air storage tank, which are used to provide relatively stable compressed air for the glue storage device.

[0020] The rubber storage device includes a pressure barrel 1, a retractable bag, an air intake valve 2, a latex valve 3 and a suction pipe 7; in the technical solution of the present application, the pressure barrel can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com