Coated sand, manufacturing method for same, and manufacturing method for mold

A manufacturing method, coated sand technology, applied in the direction of casting molds, casting mold components, manufacturing tools, etc., can solve the problems of physical property reduction, physical property change, insufficient drying, etc., and achieve the effect of increasing strength and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0068] Hereinafter, the present invention will be described more specifically using some examples, but it should be understood that the present invention should not be construed in any way as limited by the description of such examples. In addition, in the following examples and comparative examples, parts and percentages are expressed on a mass basis unless otherwise specified. In addition, the moisture content, agglomerate amount, filling rate, sand state of the coated sand (CS) obtained in the examples and comparative examples, and the measurement of the flexural strength and scratch hardness of the mold obtained by using each CS , and observation of tank adhesion during kneading were performed as follows.

[0069] -Determination of moisture content (%)-

[0070] 2.0 g of the obtained coated sand (CS) was put into a Karl Fischer moisture meter (manufactured by Hiranuma Sangyo Co., Ltd.; AQV-7HIRANUMA AQUACOUNTER) to which 100 mL of Aqua micron ML (manufactured by Mitsubish...

manufacture example 1

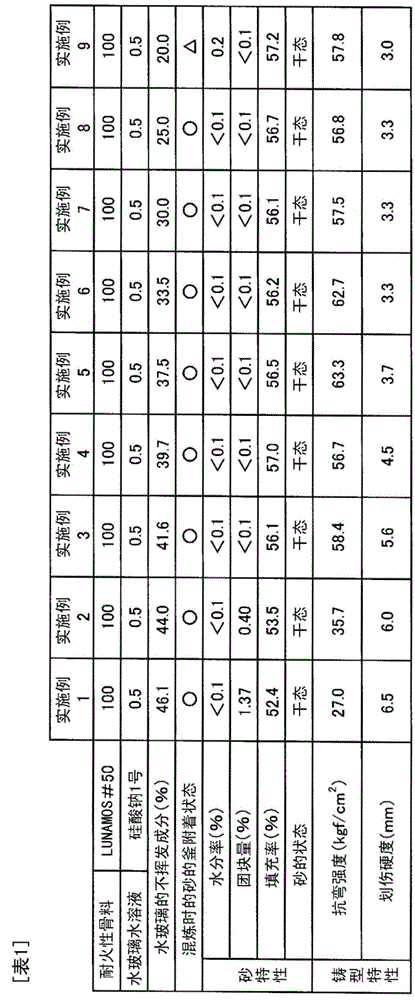

[0086] -Production Example 1 of CS (Example 1)-

[0087] As a refractory aggregate, commercially available artificial sand for foundry, namely LUNAMOS#50 (trade name: manufactured by Kao Corporation), was prepared, and as a binder, commercially available sodium silicate No. 1 (trade name: Fuji Chemical Co., Ltd. Co., Ltd.) was diluted with water so that the non-volatile content (ratio of water content subtracted from water glass aqueous solution) was 46.1%.

[0088] Next, after putting the above-mentioned LUNAMOS#50 heated to a temperature of about 120° C. into a Shinagawa-type universal mixer (5DM-r type) (manufactured by DALTON CO., LTD., JAPAN), the aforementioned water glass aqueous solution was added to the LUNAMOS Add 100 parts of #50 at a ratio of 0.5 parts in terms of solid content when only non-volatile components are considered, knead for 3 minutes to evaporate water, and then stir and mix until the sand lumps disintegrate Take it out to obtain dry coated sand (CS) ...

manufacture example 2~9

[0089] -Production Examples 2 to 9 of CS (Examples 2 to 9)-

[0090] As a binding material, prepare commercially available sodium silicate No. 1 (trade name: manufactured by Fuji Chemical Co., Ltd.) with water so that the non-volatile content is 44.0%, 41.6%, 39.7%, 37.5%, 33.5%, and 30.0%, respectively. %, 25.0% or 20.0% water glass aqueous solution, CS2-CS9 were obtained according to the procedure similar to manufacture example 1 except this.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com