Melt electro-spinning device and technology capable of mixing supercritical gas

A melt electrospinning and supercritical gas technology, which is used in the melting of filament raw materials, textile and papermaking, filament/thread forming, etc. problems, to achieve the effect of improving spinning efficiency, uniform diameter, and improving roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following are specific embodiments of the present invention, and further describe the technical solution of the present invention in conjunction with the accompanying drawings, but the present invention is not limited to these embodiments.

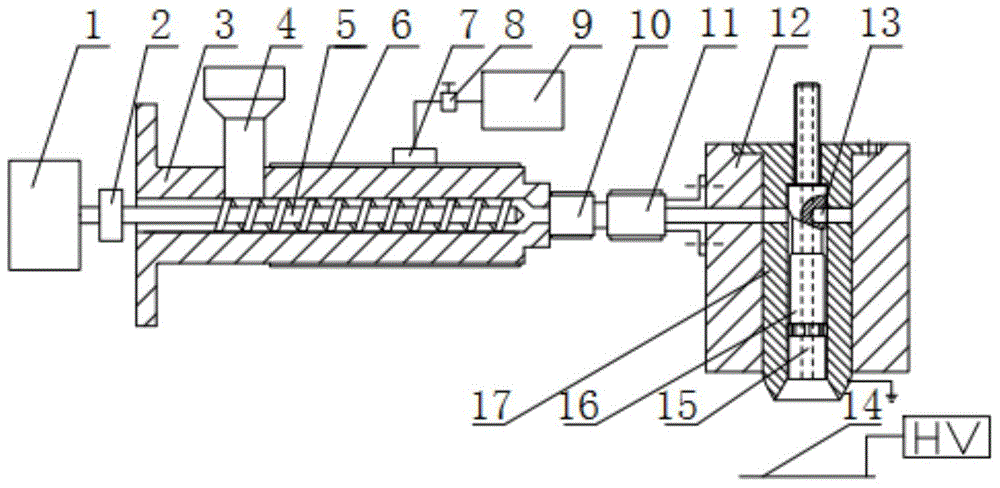

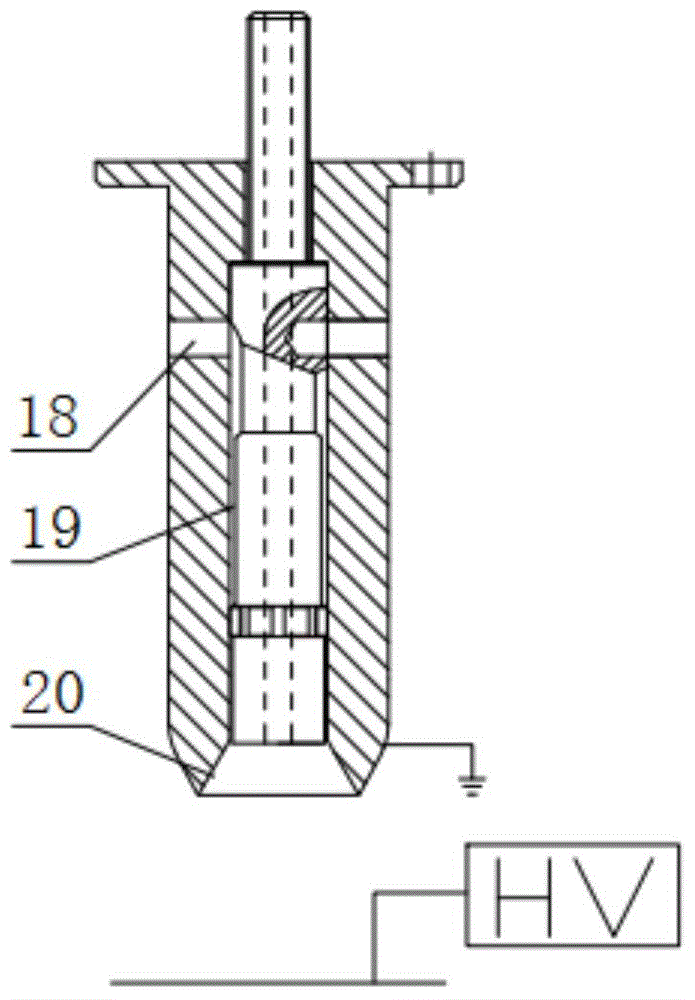

[0034] Such as figure 1 and figure 2 As shown, a melt electrospinning device mixed with supercritical gas in the present invention includes: a power unit 1, an extrusion device, a supercritical gas generator 9 and a melt electrospinning device.

[0035] Wherein, the extrusion device includes a barrel 3 and a screw 5 installed in the barrel 3 , the power unit 1 is connected to the screw 5 through a coupling 2 , and a hopper 4 is installed on the barrel 3 . A supercritical gas generator 9 communicates with the cartridge 3 . The melt electrospinning device is provided with a nozzle 17, and the melt electrospinning device is connected to the barrel 3. In the barrel 3, the polymer provided by the hopper 4 and the supercritical gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com