Method for efficiently preparing ternary laminar MAX phase ceramic coating layer at low temperature

A ternary layered, ceramic coating technology, applied in coating, metal material coating process, ion implantation plating and other directions, can solve the problems of high preparation cost and complex process, and achieve low preparation cost, simple process, Choose from a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] (1) Preparation of target material

[0037] Use M, A, X element powder or conductive binary and ternary compound powder as raw material powder, take the molar ratio of M, A, X=(n+1):1:n as the basic ratio and make appropriate adjustments, The raw material powder is mixed in a high-speed ball mill by physical and mechanical methods for 12-24 hours, dried and sieved, then put into a graphite mold and cold-pressed to shape, and the applied pressure is 1-10MPa; Conductive cathode targets (mainly containing binary compounds, intermetallic compounds and elemental elements, etc.) are made by preliminary hot pressing method. ~30MPa, the treatment time is 0.5~2 hours.

[0038] (2) Coating preparation process

[0039] The film is deposited by multi-arc ion plating or magnetron sputtering. The main process parameters are as follows: For multi-arc ion plating, the background vacuum of the deposition chamber is 1.0~3.0×10 -3 Pa, and then flow high-purity Ar gas (flow rate 20-40S...

Embodiment 1

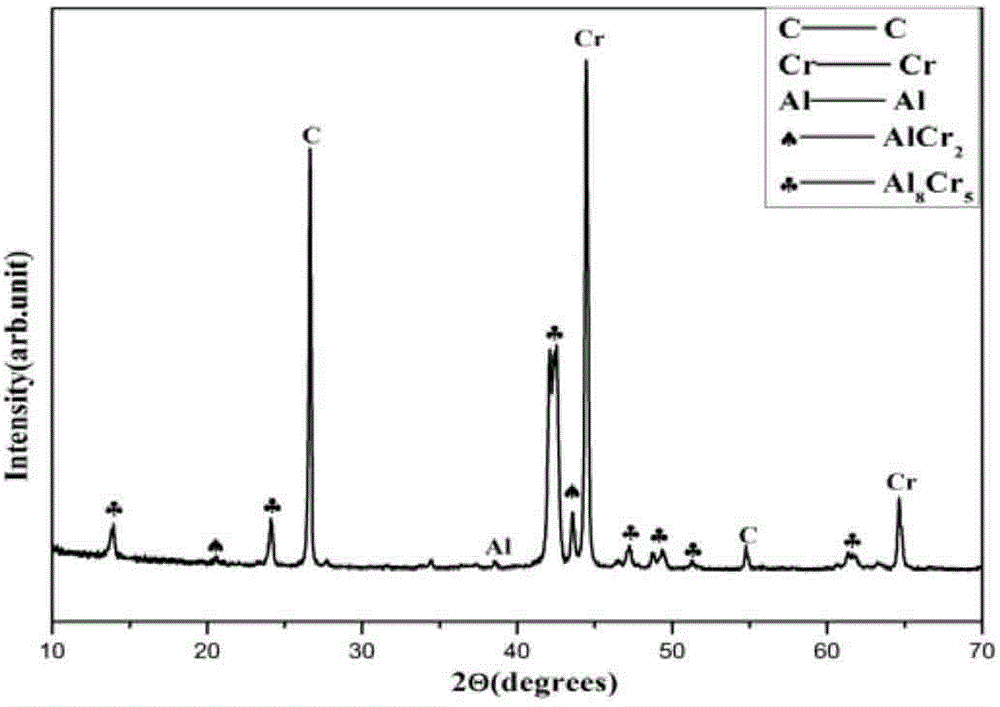

[0045] The multi-arc ion plating method is adopted, and the mixed powder of Cr, Al, and C is used as the initial raw material according to the molar ratio of 2:1.05:0.95, with alcohol as the medium, ball milled for 24 hours, dried and sieved, and loaded into a graphite mold Cold press forming, the applied pressure is 5MPa, the pressure is maintained for 10min, and the temperature is raised to 680℃ at a rate of 10℃ / min in a hot-press furnace with a flowing Ar protection atmosphere, and the pressure is simultaneously increased to 10MPa, and the heat preservation and pressure are maintained for 1 hour. Cr-Al-C target, the target resistivity is 20μΩ·m.

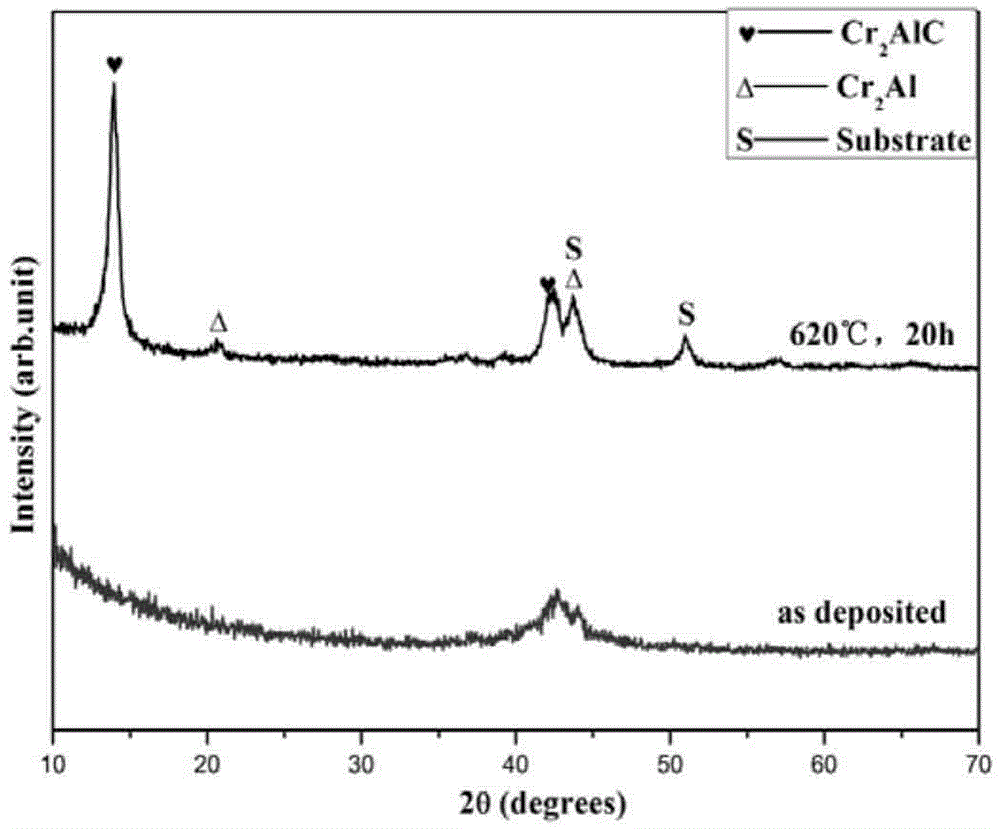

[0046] The background vacuum during the coating preparation process is 2×10 -3 The Pa and Ar gas flows are 40SCCM, the working pressure is 0.4Pa, the current applied to the target is 60A, and the deposition time is 20min. Amorphous Cr-Al-C coatings can be prepared on different substrates. The as-prepared coating was annealed in ...

Embodiment 2

[0051] Using the multi-arc ion plating method, at the same time, the three element powders of Ti, Si and C are used as the initial raw material according to the molar ratio of 3:1:2, with alcohol as the medium, ball milled for 12 hours, dried and sieved, and loaded into graphite molds Cold press molding, the applied pressure is 10MPa, the pressure is kept for 10min, and the temperature is raised to 1000℃ at a rate of 20℃ / min in a hot-press furnace with a flowing Ar protection atmosphere, and the pressure is increased to 20MPa at the same time, and the temperature is kept for 2 hours. Ti-Si-C target.

[0052] The background vacuum during the coating preparation process is 2.5×10 -3 The Pa and Ar gas flows are 40SCCM, the working pressure is 0.4Pa, the current applied to the target is 55A, and the deposition time is 30min. Amorphous Ti-Si-C coatings can be prepared on different substrates. The as-prepared coating was annealed in Ar atmosphere at 1000 °C for 1 h, and Ti 3 SiC ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com