Aqueous glass curtain wall cleaning solution and preparation method thereof

A glass curtain wall, cleaning liquid technology, applied in chemical instruments and methods, detergent compounding agents, detergent compositions, etc., can solve the problems of cumbersome steps, time-consuming and laborious, waste of water resources, etc., and achieve a wide range of effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

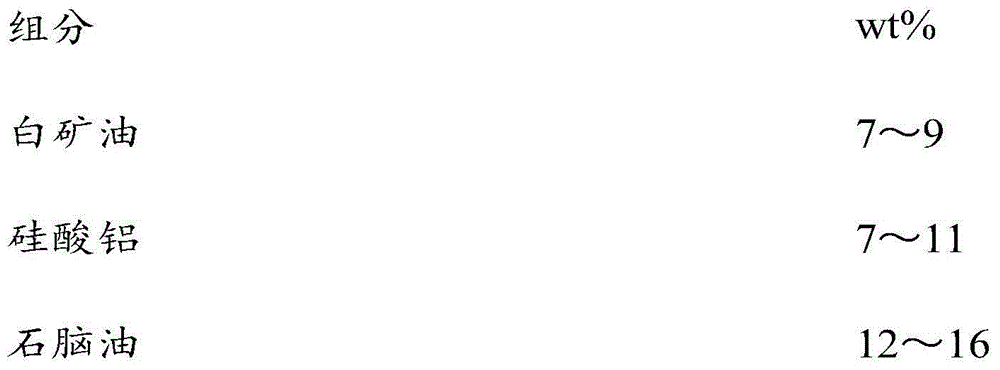

[0026] The present embodiment provides water-based glass curtain wall cleaning liquid, and its component is made up as follows according to weight percentage:

[0027]

[0028]

[0029] Wherein, the pure water is tap water with a conductivity of ≤13 after passing through the reverse osmosis membrane; the thickener is a cross-linked polymer thickener containing acidic groups; the defoamer is mineral oil; the brightener It is bistriazine aminostilbene; the coating agent is polyvinyl chloride; the surfactant is castor oil; the viscosity of the water-based glass curtain wall cleaning solution is 3CP (centipoise) at 25°C, and the water-based glass curtain wall cleaning solution is compatible with the glass surface The coefficient of friction is 0.3.

[0030] The preparation method of this aqueous glass curtain wall cleaning solution is as follows:

[0031] S1: Weigh 12% pure water by weight and pour it into a stirring container;

[0032] S2: Pour 7% by weight of white miner...

Embodiment 2

[0037] The present embodiment provides water-based glass curtain wall cleaning solution, and the components are composed as follows according to weight percentage:

[0038]

[0039] Among them, the pure water is tap water with a conductivity of ≤13 after the reverse osmosis membrane; the thickener is a non-ionic associative synergistic rheological agent; the defoamer is siloxane; the brightener is bistriazine amino Stilbene; Coating agent is polyvinyl alcohol; Surfactant is chlorinated paraffin; The viscosity of water-based glass curtain wall cleaning solution is 1CP (centipoise) at 25 ℃, and the friction coefficient of water-based glass curtain wall cleaning solution and glass surface is 0.1.

[0040] The preparation method of this aqueous glass curtain wall cleaning solution is as follows:

[0041] S1: Weigh 16% pure water by weight and pour it into a stirring container;

[0042] S2: Pour 11% by weight of white mineral oil, 11% by weight of aluminum silicate, 16% by wei...

Embodiment 3

[0047] The present embodiment provides water-based glass curtain wall cleaning liquid, and its component is made up as follows according to weight percentage:

[0048]

[0049]

[0050] Among them, the pure water is tap water after the reverse osmosis membrane, the pure water with conductivity ≤ 13; the thickener is non-ionic associative synergistic rheological agent; the defoamer is mineral oil; the brightener is bistriazine aminobiphenyl Ethylene; the coating agent is polyvinylidene chloride; the surfactant is castor oil; the viscosity of the water-based glass curtain wall cleaning solution is 2CP (centipoise) at 25°C, and the friction coefficient between the water-based glass curtain wall cleaning solution and the glass surface is 0.2 .

[0051] The preparation method of this aqueous glass curtain wall cleaning solution is as follows:

[0052] S1: Weigh 11% pure water by weight and pour it into a stirring container;

[0053] S2: Pour 7% by weight of white mineral oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com