Aqueous polyurethane coating with increased limiting film thickness and preparation method of aqueous polyurethane coating

A water-based polyurethane and coating technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problem that the limit film thickness requirements of polyurethane coatings have not been reached, and achieve high limit film thickness and weather resistance, weather resistance and good appearance quality , the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below through specific embodiment, further describe the present invention.

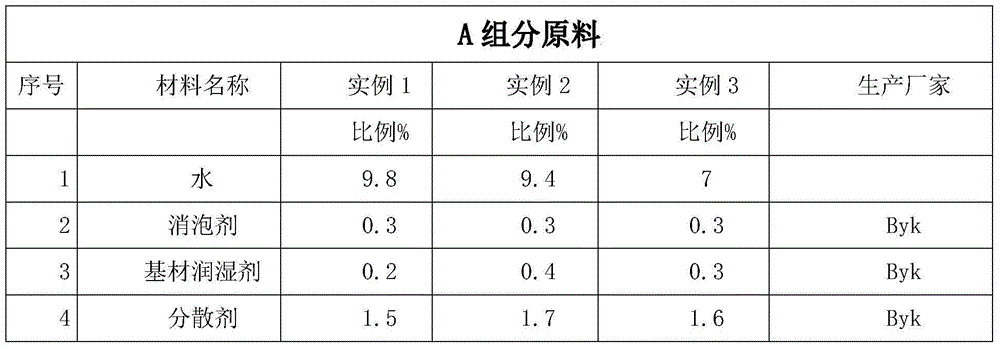

[0033] First, raw material preparation:

[0034]

[0035]

[0036]

[0037] Next, preparation steps:

[0038] Component A: add 1-4 (defoamer is added under high shear stress), stir evenly, add 5 under high-speed stirring, add zirconium beads to grind until the fineness is less than 10 μm, add 6-10 at a reduced speed, and stir After being uniform, component A of the water-based polyurethane coating is prepared.

[0039] Component B: Add 1-4 and stir well to prepare component B of water-based polyurethane.

[0040] Finally, the performance test of the obtained paint is tested according to the test method specified in the corresponding national standard, and the performance is as follows:

[0041]

[0042]

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com