Ultrahigh-weather-resistance PVC (polyvinyl chloride) coextruded surface material and manufacturing method thereof

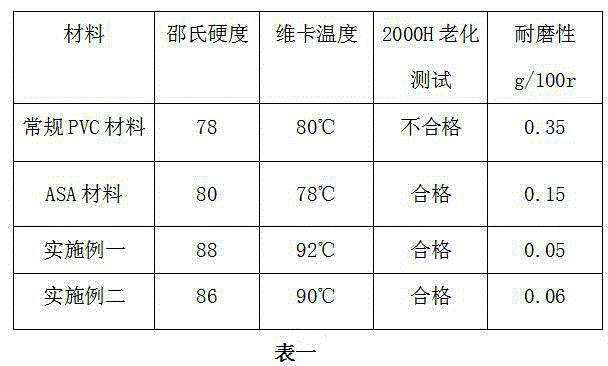

A surface layer material and weather resistance technology, applied in the field of composite materials, can solve the problems of high price, reduced surface wear resistance and rigidity, insufficient weather resistance, etc., and achieve the effect of low cost, simple manufacturing method and stable product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The ultra-high weather resistance PVC co-extruded surface layer material of this implementation comprises the mass fraction ratio of following materials:

[0047] PVC powder is 40 parts, and the PVC powder of the present embodiment is ethylene method PVC, and ethylene method PVC adopts the SG5 type PVC powder that degree of polymerization is 1000;

[0048] CPVC powder is 30 parts, and the CPVC powder of the present embodiment is the perchlorethylene of chlorine content ≥ 65%;

[0049] Calcium carbonate powder is 10 parts, and the calcium carbonate powder of the present embodiment is 1250 purpose ground calcium carbonate powders;

[0050] The stabilizing agent is 5 parts, and the stabilizing agent of the present embodiment is a calcium-zinc environment-friendly composite stabilizing agent;

[0051] The impact modifier is 4 parts, and the impact modifier of the present embodiment is a blend of ACR and CPE, wherein ACR accounts for 65%, and CPE accounts for 40%;

...

Embodiment 2

[0064] The ultra-high weather resistance PVC co-extruded surface layer material of this implementation comprises the mass fraction ratio of following materials:

[0065] PVC powder is 45 parts, and the PVC powder of the present embodiment is ethylene method PVC, and ethylene method PVC adopts the SG5 type PVC powder that degree of polymerization is 1000;

[0066] CPVC powder is 29 parts, and the CPVC powder of the present embodiment is the perchlorethylene of chlorine content ≥ 65%;

[0067] Calcium carbonate powder is 12 parts, and the calcium carbonate powder of the present embodiment is 1250 object heavy calcium carbonate powders;

[0068] Stabilizer is 0.5 part, and the stabilizer of the present embodiment is organotin stabilizer;

[0069] The impact modifier is 5 parts, and the impact modifier of the present embodiment is a blend of ACR and CPE, wherein ACR accounts for 65%, and CPE accounts for 40%;

[0070] The lubricant is 1 part. The lubricant in this embodim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vicat softening point | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com