Ionic liquid polymer grafted magnetic carbon nanotube and preparation method thereof

A technology of magnetic carbon nanotubes and polymerized ionic liquids, which is applied in the field of surface modification of carbon nanotubes, can solve the problems of non-dispersion of carbon nanotubes, limitations on the use of carbon nanotubes, etc., and achieves the effects of easy operation and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Ethyl bromide (3.70g, 34mmol) was added dropwise to 1-vinylimidazole (1.88g, 20mmol), refluxed at 50°C for 16h, cooled to room temperature, filtered, washed with sufficient ethyl acetate, and dried under vacuum at 50°C to obtain Pale yellow solid powder 1-ethyl-3-vinylimidazolium bromide, yield 81%.

[0042] Put the mixed acid solution of 4g of original carbon nanotubes, concentrated sulfuric acid (98%, 120mL) and concentrated nitric acid (68%, 40mL) in a 250mL glass beaker, mix and sonicate for 8h, after cooling to room temperature, pour the reaction mixture into 800mL Stand overnight in deionized water, and after the carbon nanotubes settle down, pour out the upper layer solution, repeat this operation three times, wash with 0.22 μm polycarbonate membrane until neutral, and dry at 60°C for 12 hours in vacuum to obtain acidified carbon nanotubes. Tube.

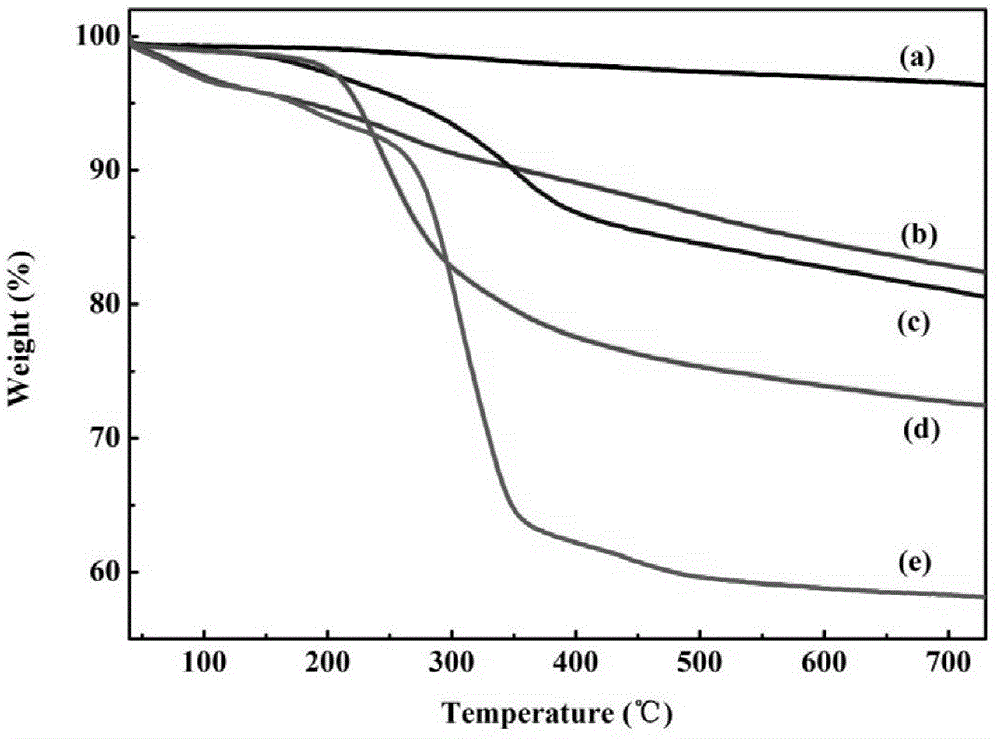

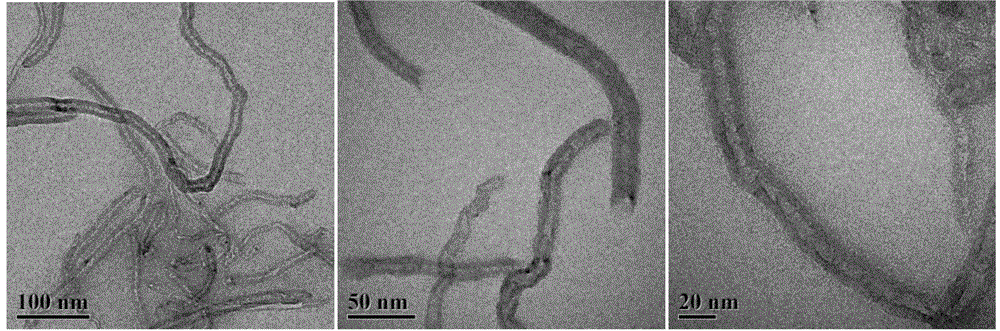

[0043] At a temperature of 65° C., 3 g of acidified carbon nanotubes were added to 80 mL of thionyl chloride to rea...

Embodiment 2

[0050] Bromobutane (4.66g, 34mmol) was added dropwise to 1-vinylimidazole (1.88g, 20mmol), refluxed at 50°C for 16h, cooled to room temperature, filtered, washed with enough ethyl acetate, vacuumed at 50°C Dry to give 1-butyl-3-vinylimidazolium bromide.

[0051] Put the mixed acid solution of 4g of original carbon nanotubes, concentrated sulfuric acid (98%, 120mL) and concentrated nitric acid (68%, 40mL) in a 250mL glass beaker, mix and sonicate for 8h, after cooling to room temperature, pour the reaction mixture into 800mL Stand in deionized water overnight, after the carbon nanotubes settle down, pour out the upper layer solution, repeat this operation three times, wash with 0.22 μm polycarbonate membrane until neutral, and dry in vacuum at 60°C for 12 hours. At a temperature of 65° C., 3 g of acidified carbon nanotubes were added to 80 mL of thionyl chloride to react for 24 hours. After the reaction, the mixture was filtered, washed with dry tetrahydrofuran, and dried at ro...

Embodiment 3

[0056] Bromo-n-hexane (5.16g, 34mmol) was added dropwise to 1-vinylimidazole (1.88g, 20mmol), refluxed at 50°C for 16h, cooled to room temperature, filtered, washed with enough ethyl acetate, and dried under vacuum at 50°C In 1-hexyl-3-vinylimidazolium bromide.

[0057] Put the mixed acid solution of 4g of original carbon nanotubes, concentrated sulfuric acid (98%, 120mL) and concentrated nitric acid (68%, 40mL) in a 250mL glass beaker, mix and sonicate for 8h, after cooling to room temperature, pour the reaction mixture into 800mL Stand in deionized water overnight, after the carbon nanotubes settle down, pour out the upper layer solution, repeat this operation three times, wash with 0.22 μm polycarbonate membrane until neutral, and dry in vacuum at 60°C for 12 hours. At a temperature of 65° C., 3 g of acidified carbon nanotubes were added to 80 mL of thionyl chloride to react for 24 hours. After the reaction, the mixture was filtered, washed with dry tetrahydrofuran, and dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com