Micro-channel chemical preparation method of porous metal-organic framework material

An organic framework and porous metal technology, applied in the field of microchannel chemical preparation of porous metal organic framework materials, can solve the problems of large equipment volume, long residence time, poor mixing effect, etc., and achieve the effect of high surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Add 12g of copper acetate to 350ml of deionized water to make solution A, add 8g of trimesic acid to 350ml of ethanol to make solution B; filter A and B, add T-type quartz at a flow rate of 0.5ml / min In the two inlet microchannels of the circular hole microchannel reactor, the angle between the inlet microchannels is 180°, and the angle between each inlet microchannel and the reaction microchannel is 90°, the length of the reaction microchannel is 8m, and the inner diameter is 0.23mm , the microchannel reaction temperature is 80°C; react for 8 hours, and collect the product directly. After filtering, washing once with 200ml of ethanol and once with 100ml of acetone, and drying at 60°C for 6 hours, 9g of porous Cu-BTC framework material was obtained.

[0048] N 2 The specific surface area is 876m 2 / g (as determined by the Langmuir method).

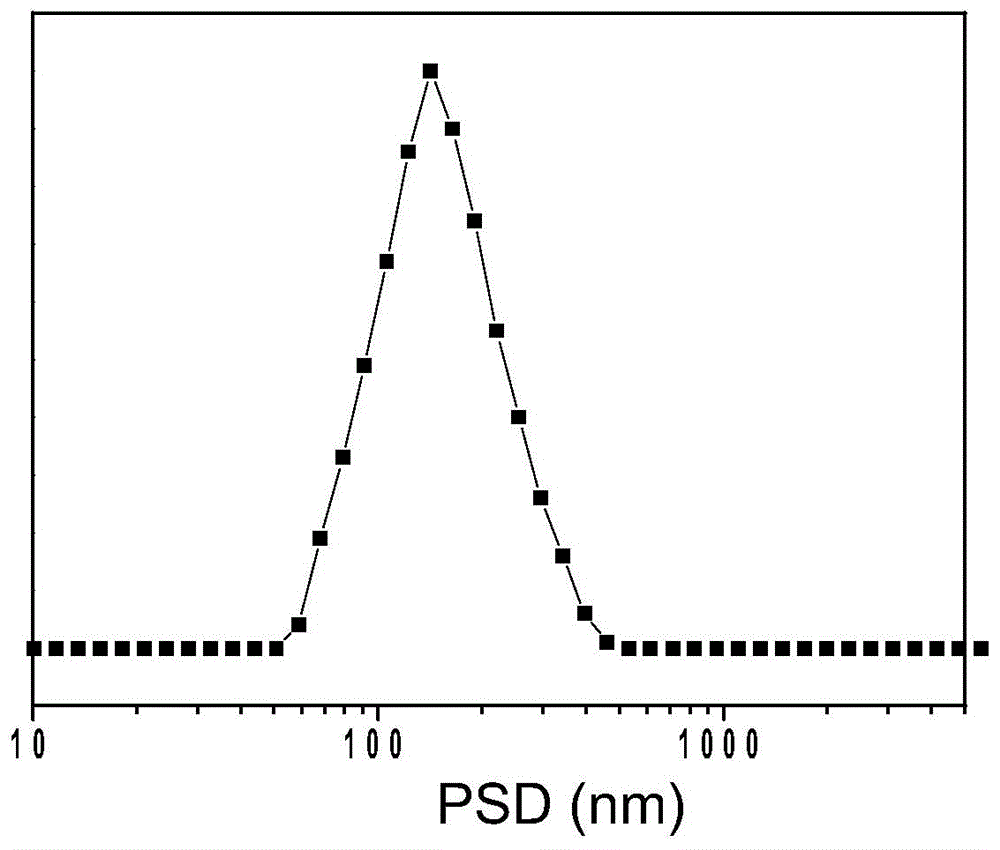

[0049] figure 1 It is the particle size distribution diagram of the obtained product (measured by Malvern particle size analyz...

Embodiment 2

[0051] Add 12g of copper acetate to 250ml of deionized water to make solution A, add 8g of trimesic acid to 250ml of ethanol to make solution B; filter A and B, add T-type quartz at a flow rate of 0.5ml / min In the two inlet microchannels of the circular hole microchannel reactor, the angle between the inlet microchannels is 180°, and the angle between each inlet microchannel and the reaction microchannel is 90°, the length of the reaction microchannel is 8m, and the inner diameter is 0.23mm , the microchannel reaction temperature is 80°C; collect the feed liquid at the outlet of the reactor, then transfer the feed liquid into the reactor, and age at 100°C for 10h. After filtering, washing once with 200ml of ethanol and once with 100ml of acetone, and drying at 60°C for 6 hours, 12g of porous Cu-BTC framework material was obtained.

[0052] N 2 The specific surface area is 1013m 2 / g (as determined by the Langmuir method).

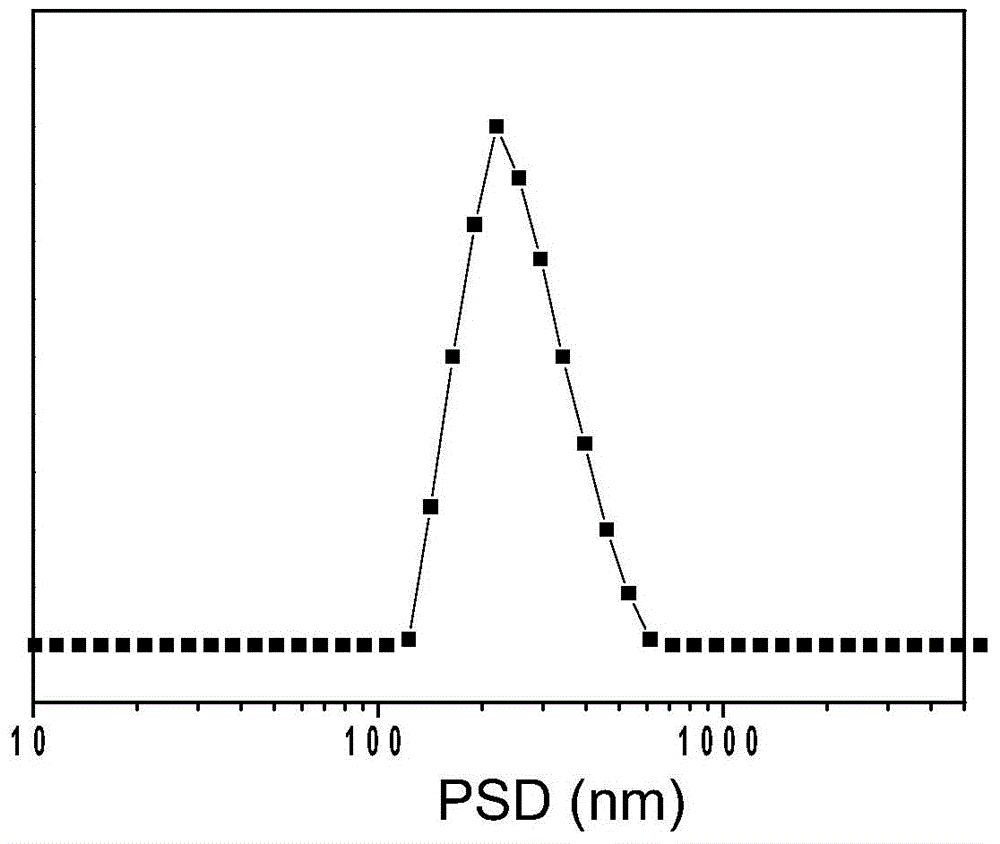

[0053] figure 2 It is the particle size distribu...

Embodiment 3

[0055] Add 36g of copper acetate to 1050ml of deionized water to make solution A, add 25g of trimesic acid to 1050ml of ethanol to make solution B; filter A and B, add T-shaped quartz circle at a flow rate of 3ml / min In the two inlet microchannels of the well microchannel reactor, the angle between the inlet microchannels is 90°, the angle between the B liquid inlet microchannel and the reaction microchannel is 90°, the length of the reaction microchannel is 10m, and the inner diameter is 0.5mm. The channel reaction temperature is 80°C; react for 3 hours, collect the product directly, and then enter the feed liquid into a 2L reactor for aging reaction at 100°C for 10 hours. After filtering, washing once with 200ml of ethanol and once with 100ml of acetone, and drying at 80°C for 4 hours, 15g of porous Cu-BTC framework material was obtained.

[0056] N 2 The specific surface area is 1076m 2 / g (as determined by the Langmuir method).

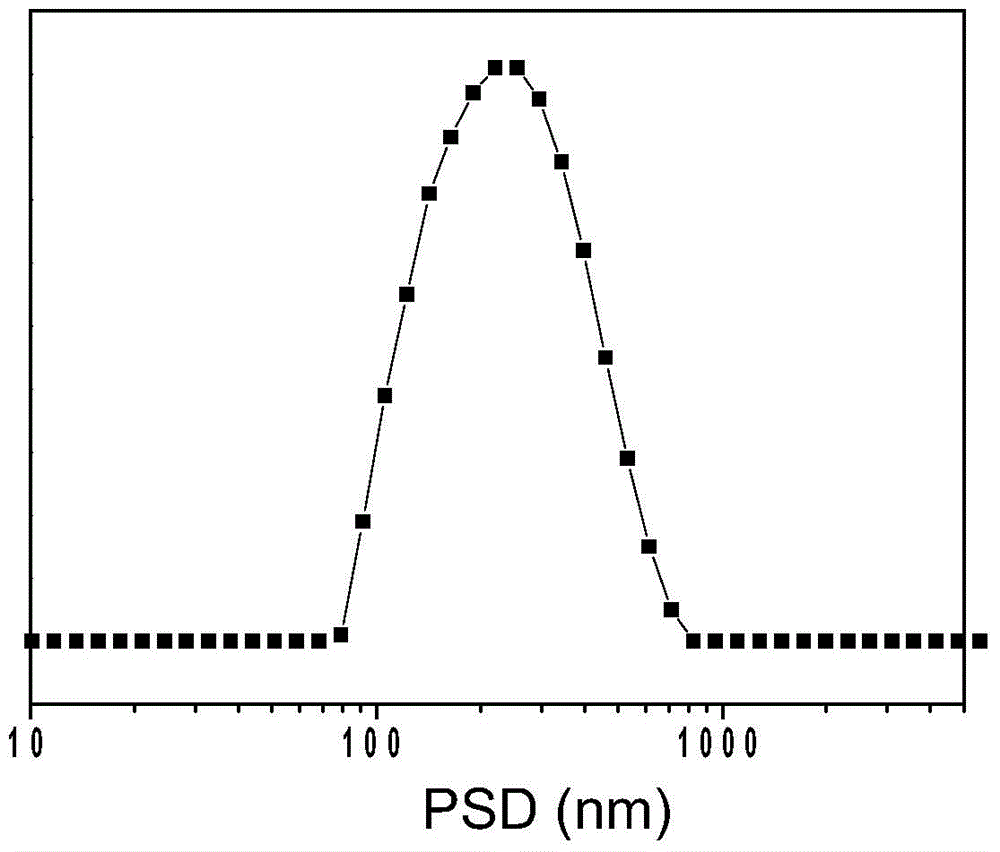

[0057] image 3 It is the particle size...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com