Method for manufacturing corrosion-resistant and flame-retardant glass steel grid through pultrusion profile production system

A production system and technology of pultrusion profiles, applied in the field of composite material manufacturing, can solve problems such as poor wear resistance and achieve high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

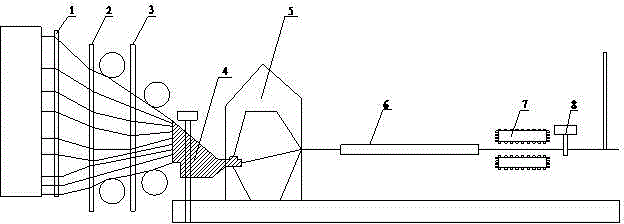

[0024] Example 1: A method of manufacturing corrosion-resistant and flame-retardant FRP gratings through a pultrusion profile production system, the steps are as follows: evenly wind glass fiber filaments into a hollow cylinder, place the hollow cylinder on a rotating roller, The fiber filament rotating roller is placed on the creel on the yarn field for standby, and at the same time, the filament end of the glass fiber filament is pulled out to be put into the guide plate; the filament end is guided into the guide system, and the guide system includes the first guide plate 1, the second guide plate The guide plate 2 and the third guide plate 3, there is a transmission roller between the second guide plate 2 and the third guide plate 3, and the filament head is fixed through each guide plate and the transmission roller so that the glass fiber filament can be continuously transmitted to the impregnation equipment 4. The first guide plate 1, the second guide plate 2 and the third...

Embodiment 2

[0025] Example 2: Unsaturated polyester resin, flame retardant, anti-aging agent, curing agent, accelerator, and anti-falling agent are composed of a flame retardant resin mixture and injected into the impregnation device 4, and its mass ratio is 100:10:3:1 :2:0.5, the curing agent is a mixture of ketone peroxides, the accelerator is a cobalt accelerator, the anti-falling agent is silicon dioxide, and the anti-aging agent is a UV anti-aging agent; the heating and curing device 6 has a pressurizing function at the same time, The heating and curing temperature is 120°C, and the heating time is maintained for 1.5 hours. After curing, it is cooled and demolded.

Embodiment 3

[0026] Example 3: Unsaturated polyester resin, flame retardant, anti-aging agent, curing agent, accelerator, and anti-falling agent are composed of a flame retardant resin mixture and injected into the impregnation device 4, and its mass ratio is 100:30:5:2 : 3: 1.5, the curing agent is a mixture of ketone peroxides, the accelerator is a cobalt accelerator, the anti-falling agent is silicon dioxide, and the anti-aging agent is a UV anti-aging agent; the heating and curing device 6 has a pressurization function at the same time, The heating and curing temperature is 150°C, and the heating time is maintained for 2 hours. After curing, it is cooled and demolded.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com