Cage porous platinum-palladium composite nanoparticle having excellent catalysis performance on methanol, and preparation method thereof

A technology of composite nanoparticles and catalytic properties, applied in chemical instruments and methods, nanotechnology for materials and surface science, nanotechnology, etc., to achieve the effects of low preparation temperature, high yield, and easy operation of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

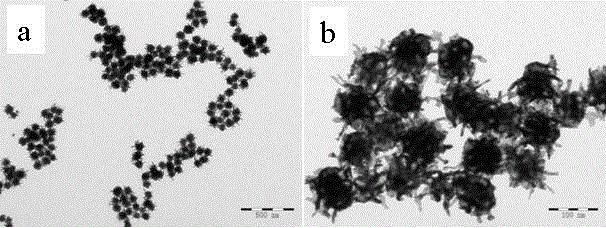

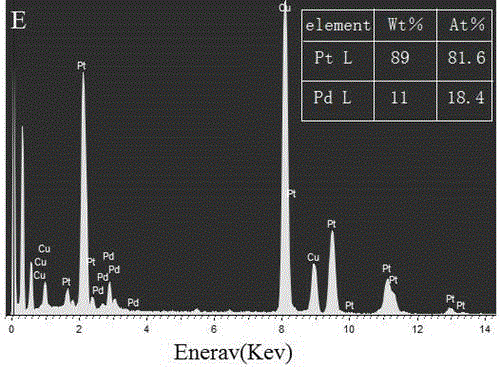

[0031] Preparation of cage-like porous platinum-palladium composite nanoparticles (80:20 platinum-palladium atomic percentage)

[0032] First add sodium tetrachloroplatinate (Na 2 PtCl 4 ), potassium chloropalladate (K 2 PdCl 4 ), hydrochloric acid (HCl), polyoxyethylene-polyoxypropylene-polyoxyethylene (P123) aqueous solution, shake well to obtain a mixed solution; then quickly add ascorbic acid (AA) to obtain a reaction precursor solution, tetrachloride in the precursor solution Sodium Platinate (Na 2 PtCl 4 ), potassium chloropalladate (K 2 PdCl 4 ), hydrochloric acid (HCl), polyoxyethylene-polyoxypropylene-polyoxyethylene (P123), ascorbic acid (AA) concentrations are 0.008 mol / L, 0.002 mol / L, 0.06 mol / L, 0.00007 mol / L, 0.05 mol / L; transfer the precursor solution to a KQ2200DA digitally controlled ultrasonic instrument, and ultrasonicate for 4 hours at 35°C to obtain a cage-like porous platinum-palladium nanocolloid solution; use a high-speed centrifuge to centrif...

Embodiment 2

[0034] Preparation of cage-like porous platinum-palladium composite nanoparticles (platinum-palladium atomic percentage 75:25)

[0035] First add sodium tetrachloroplatinate (Na 2 PtCl 4 ), potassium chloropalladate (K 2 PdCl 4 ), hydrochloric acid (HCl), polyoxyethylene-polyoxypropylene-polyoxyethylene (P123) aqueous solution, shake well to obtain a mixed solution; then quickly add ascorbic acid (AA) to obtain a reaction precursor solution, tetrachloride in the precursor solution Sodium Platinate (Na 2 PtCl 4 ), potassium chloropalladate (K 2 PdCl 4 ), hydrochloric acid (HCl), triembedded polymer Pluronic P123, and ascorbic acid (AA) concentrations were 0.0075 mol / L, 0.0025 mol / L, 0.06 mol / L, 0.00007 mol / L, 0.05 mol / L; the precursor solution Transfer to a KQ2200DA numerically controlled ultrasonic instrument, and ultrasonicate at 35°C for 4 hours to obtain a cage-like porous platinum-palladium nanocolloid solution; use a high-speed centrifuge to centrifuge at a spee...

Embodiment 3

[0037] Preparation of cage-like porous platinum-palladium composite nanoparticles (platinum-palladium atomic percentage 95:5)

[0038] First add sodium tetrachloroplatinate (Na 2 PtCl 4 ), potassium chloropalladate (K 2 PdCl 4 ), hydrochloric acid (HCl), polyoxyethylene-polyoxypropylene-polyoxyethylene (P123) aqueous solution, shake well to obtain a mixed solution; then quickly add ascorbic acid (AA) to obtain a reaction precursor solution, tetrachloride in the precursor solution Sodium Platinate (Na 2 PtCl 4 ), potassium chloropalladate (K 2 PdCl 4 ), hydrochloric acid (HCl), polyoxyethylene-polyoxypropylene-polyoxyethylene (P123), ascorbic acid (AA) concentrations are 0.0095 mol / L, 0.0005 mol / L, 0.06 mol / L, 0.00007 mol / L, 0.05 mol / L; transfer the precursor solution to a KQ2200DA numerically controlled ultrasonic instrument, and ultrasonicate at 35°C for 4 hours to obtain a cage-like porous platinum-palladium nanocolloid solution; use a high-speed centrifuge to centr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com