Combined fully organic high molecular material artificial knee joint

An organic polymer, artificial knee joint technology, applied in the field of combined all-organic polymer material artificial knee joints, can solve problems such as lack of practical application, and achieve the effects of reducing stress shielding problems, reducing pain, and reducing metal corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

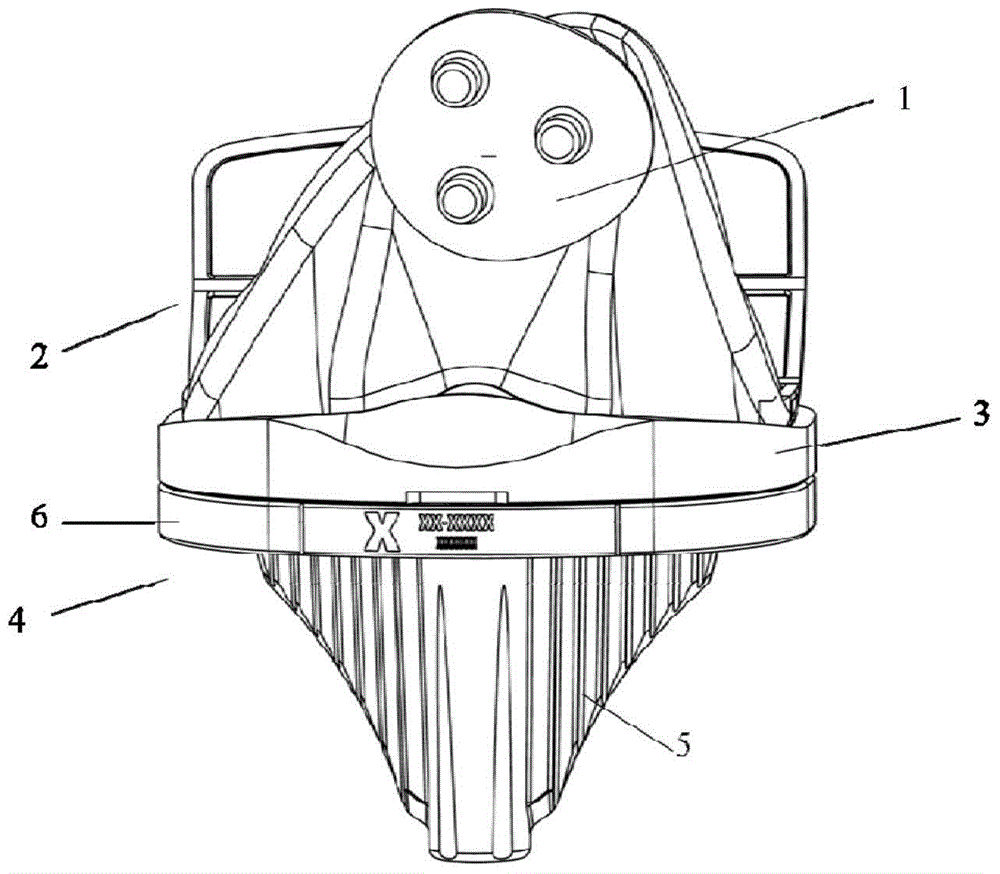

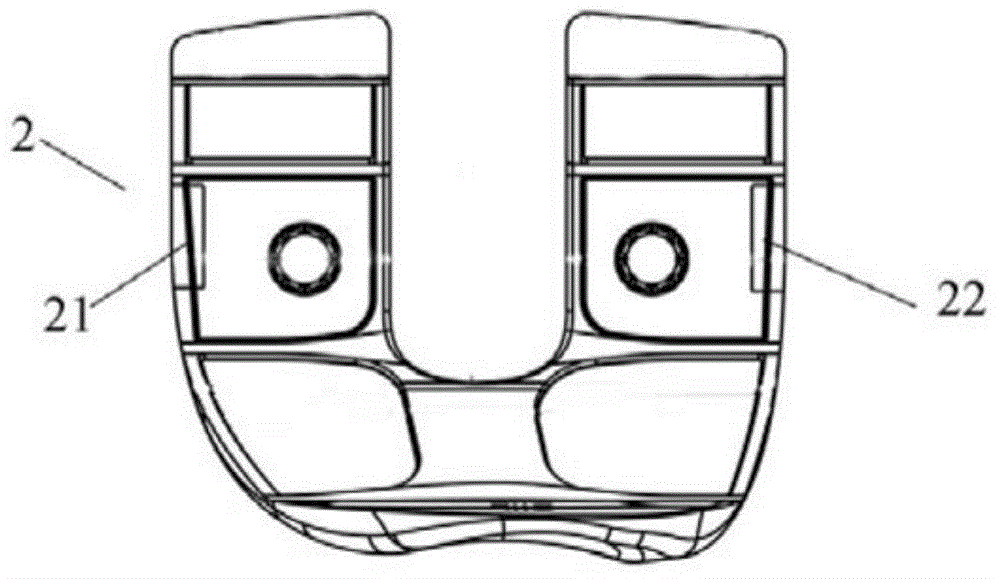

[0038] Such as figure 1 , 3 Shown in and 6, a kind of composite all-organic macromolecular material artificial knee joint provided by the present invention comprises femoral condyle 2, tibial liner 3, tibial support 4 and patella 1, wherein tibial support 4 comprises tibial support platform 6 and has The stabilizing wing positioning part 5 of a certain section, the stabilizing wing positioning part 5 is arranged below the tibial support platform 6 and perpendicular to the tibial support platform 6, and is used to fix the tibial support 4 and then the entire artificial knee joint on the human skele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com