High-strength small-bore metal bone trabecula and preparation method of same

A metal bone, small-aperture technology, applied in bone implants, additive processing, etc., can solve the problems of reduced mechanical properties, inability to realize the bone mass of the scaffold, and difficulty in meeting the mechanical properties of trabecular bone, etc., to achieve small-aperture , Facilitate bone ingrowth and cell growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

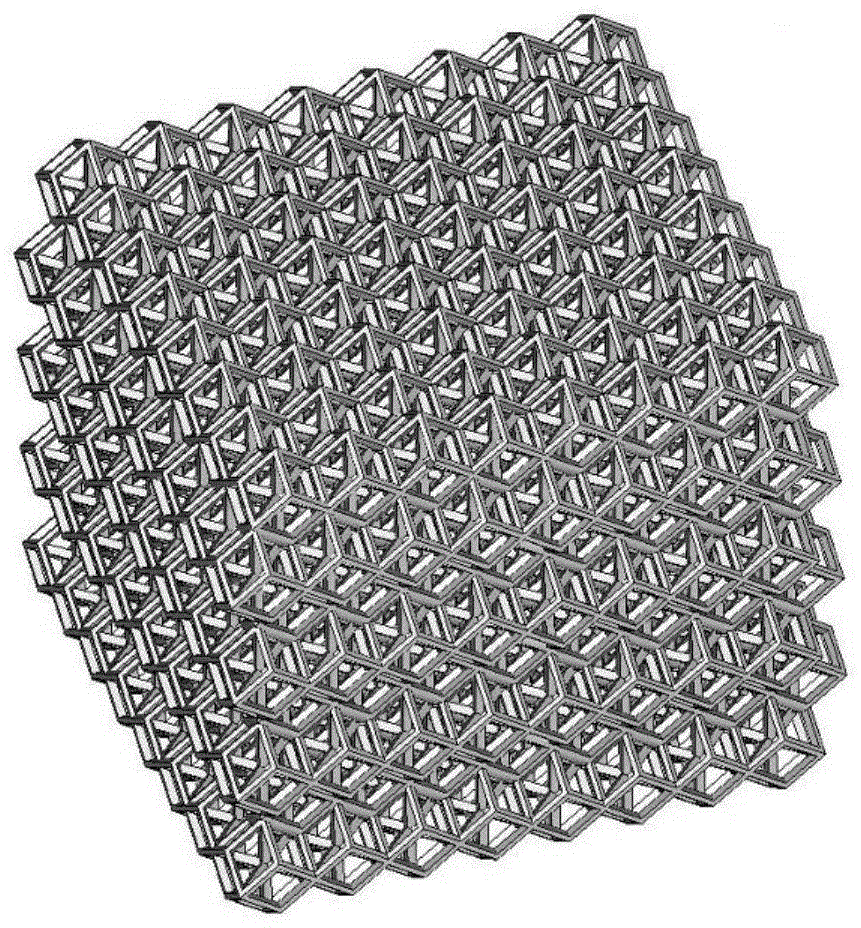

[0040] Such as figure 1 and Figure 4As shown, the high-strength small-aperture metal trabecular bone in this embodiment is a three-dimensional structure composed of a plurality of basic units superimposed. It is a rhombic dodecahedron with a side length of 2 mm. The cross-sectional shape of edge 1 is preferably a square with a side length of 0.3 mm. There is a superimposed surface between two adjacent basic units, and reinforcing ribs are also arranged inside the substrate unit. 2. The reinforcing rib 2 in this embodiment is preferably composed of 6 rods connecting the geometric center to the apex of the basic unit, and the cross-sectional shape of each rod is a square with a side length of 0.3 mm. The material of the high-strength small-aperture metal trabecular bone in this embodiment is preferably TC4 titanium alloy, and the shape of the high-strength small-aperture metal trabecular bone in this embodiment is hexahedral.

[0041] combine figure 1 with Figure 4 , the p...

Embodiment 2

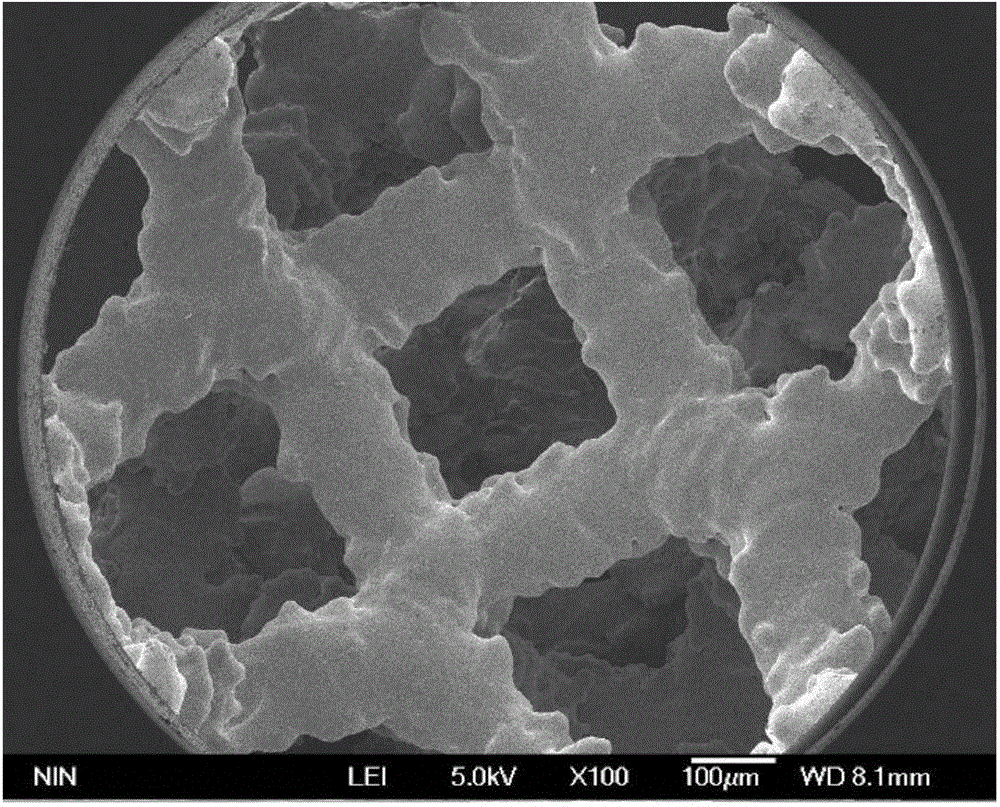

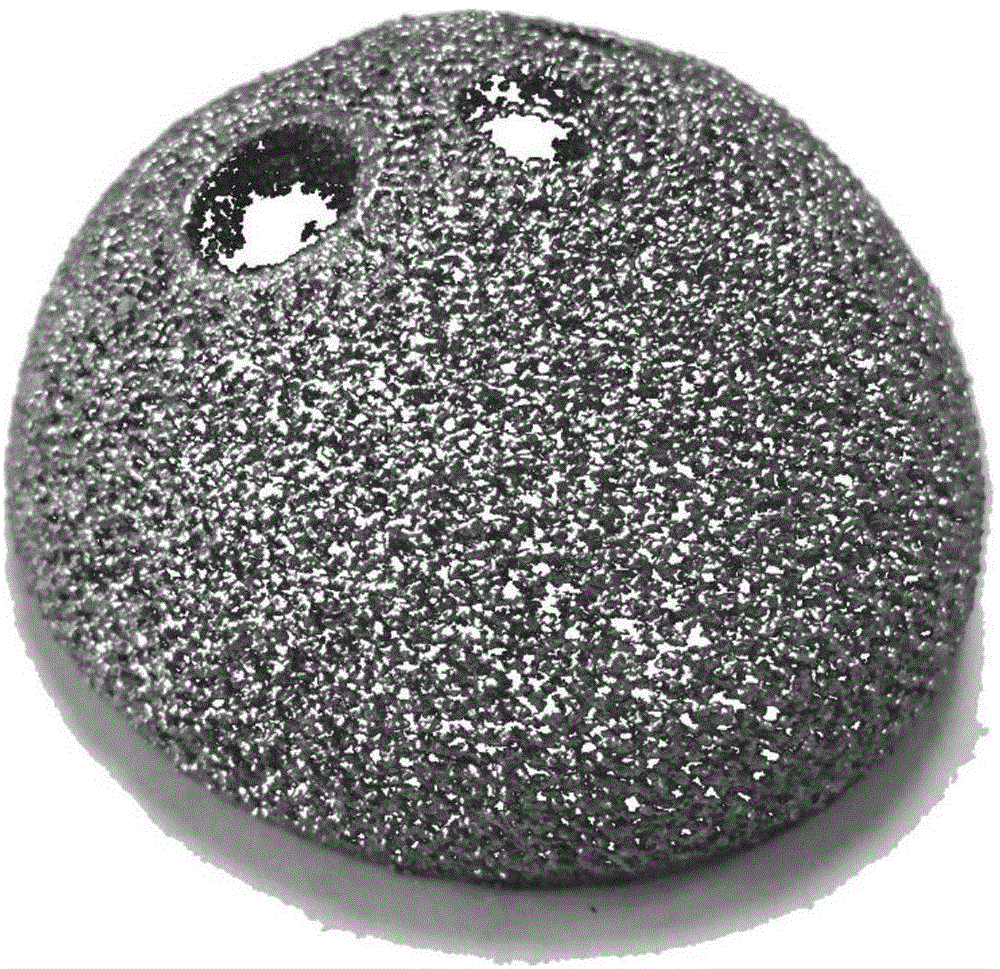

[0053] Such as image 3 with Figure 4 As shown, the high-strength small-aperture metal trabecular bone in this embodiment is a three-dimensional structure composed of a plurality of basic units superimposed. It is a rhombic dodecahedron with a side length of 0.5 mm, and the cross-sectional shape of the edge 1 is preferably an equilateral triangle with a side length of 0.15 mm. There is a superimposed surface between two adjacent basic units, and the inside of the substrate unit is also provided with The reinforcing rib 2, the reinforcing rib 2 in this embodiment is preferably composed of 6 rods connecting the geometric center to the apex of the basic unit, and the cross-sectional shape of each rod is a square with a side length of 0.15 mm. The material of the high-strength small-aperture metal trabecular bone in this embodiment is preferably TC4 titanium alloy. The acetabular cup is provided with three through holes.

[0054] combine figure 2 with Figure 4 , the prepar...

Embodiment 3

[0067] Such as Figure 5 with Figure 7 As shown, the high-strength small-aperture metal trabecular bone in this embodiment is a three-dimensional structure composed of a plurality of basic units superimposed. It is a triangular bipyramid with a side length of 0.5 mm. The cross-sectional shape of the edge 1 is preferably a square with a side length of 0.1 mm. There is a superimposed surface between two adjacent basic units, and a reinforcement is arranged inside the substrate unit. Rib 2, the reinforcing rib 2 in this embodiment is preferably composed of 5 rods connecting the geometric center to the apex of the basic unit, and the cross-sectional shape of each rod is a square with a side length of 0.1 mm. The material of the high-strength small-aperture metal trabecular bone in this embodiment is preferably TC4 titanium alloy, and the shape of the high-strength small-aperture metal trabecular bone in this embodiment is hexahedral.

[0068] combine Figure 5 with Figure 7 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com