Method for extracting lithium from solution containing lithium

A lithium solution and lithium extraction technology, applied in chemical instruments and methods, extraction water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of difficulty in recovering lithium carbonate and extracting lithium, and achieve a high recovery rate , the effect of efficient extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0165] Example 1: Concentrating the brine containing carbonate ions and separating the precipitate from solid-liquid

[0166] According to the following table 1, the preparation containing Li, Na, K, SO 4 , Cl, CO 3 etc. solution.

[0167] [Table 1]

[0168]

[0169] For the prepared as above containing Li, Na, K, SO 4 , Cl, CO 3 etc., using an evaporating concentrator, and evaporated under reduced pressure at a temperature of 40°C.

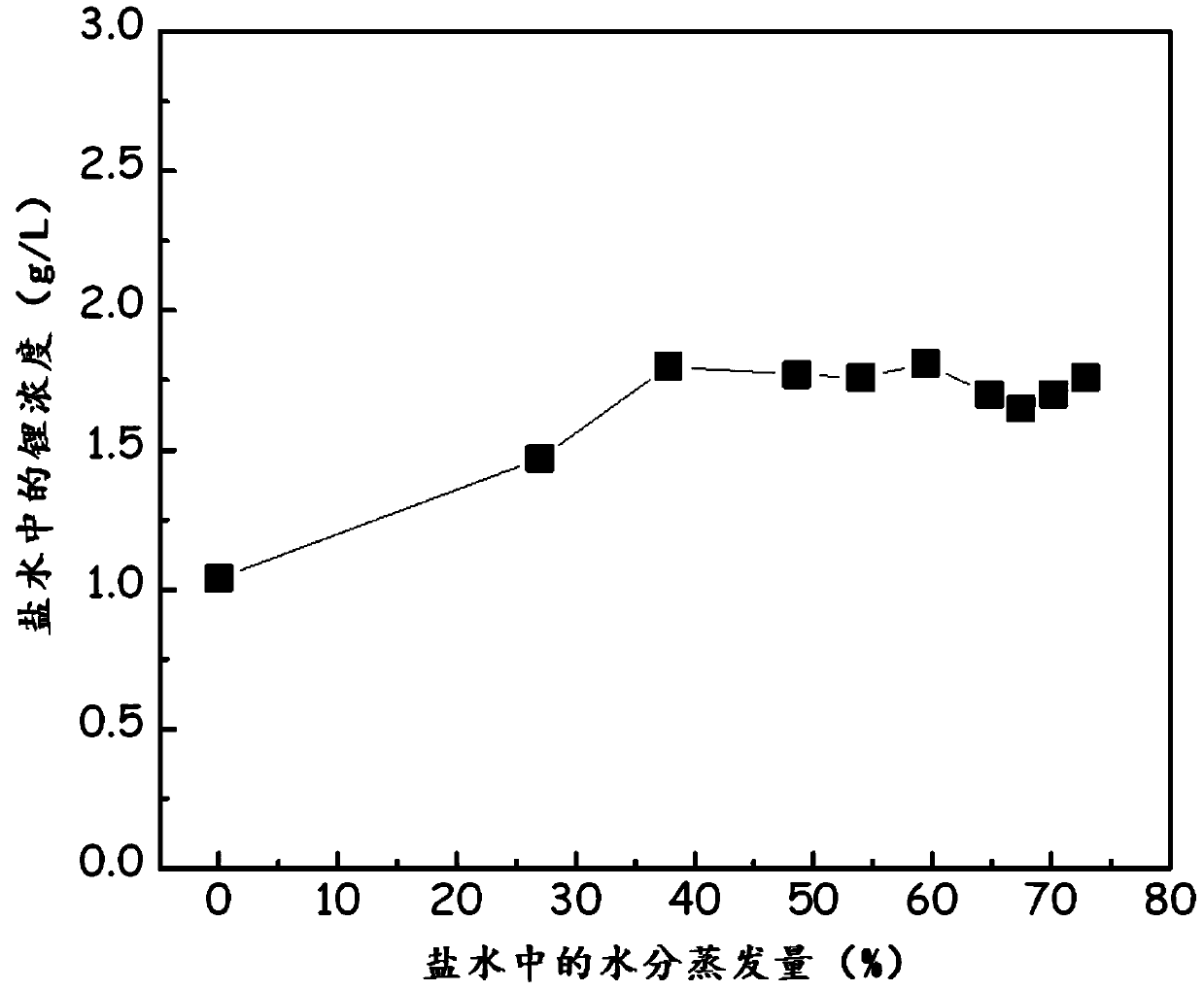

[0170] figure 1 Data showing changes in the concentration of lithium ions in the filtrate according to the amount of water evaporation when brine is concentrated.

[0171] When the brine is concentrated, as the water evaporates, the lithium concentration in the brine starts to rise from the initial 1.04g / L, and increases to 1.80g / L when the water evaporation is 37.8%.

[0172] However, when the water evaporation was greater than or equal to 37.8%, the lithium concentration did not increase even though the brine was concentrated, becau...

Embodiment 2

[0175] Example 2: Extraction of lithium phosphate from concentrated brine

[0176] Table 2 below shows the dissolved ion concentration in the filtered solution after evaporating 37.8% of the water in the brine containing a large amount of carbonate ions.

[0177] [Table 2]

[0178]

[0179] The lithium concentration of the concentrated filtered solution was 1.8 g / L, and after adding phosphoric acid equivalent to the lithium concentration equivalent, the lithium concentration was measured at room temperature at different times.

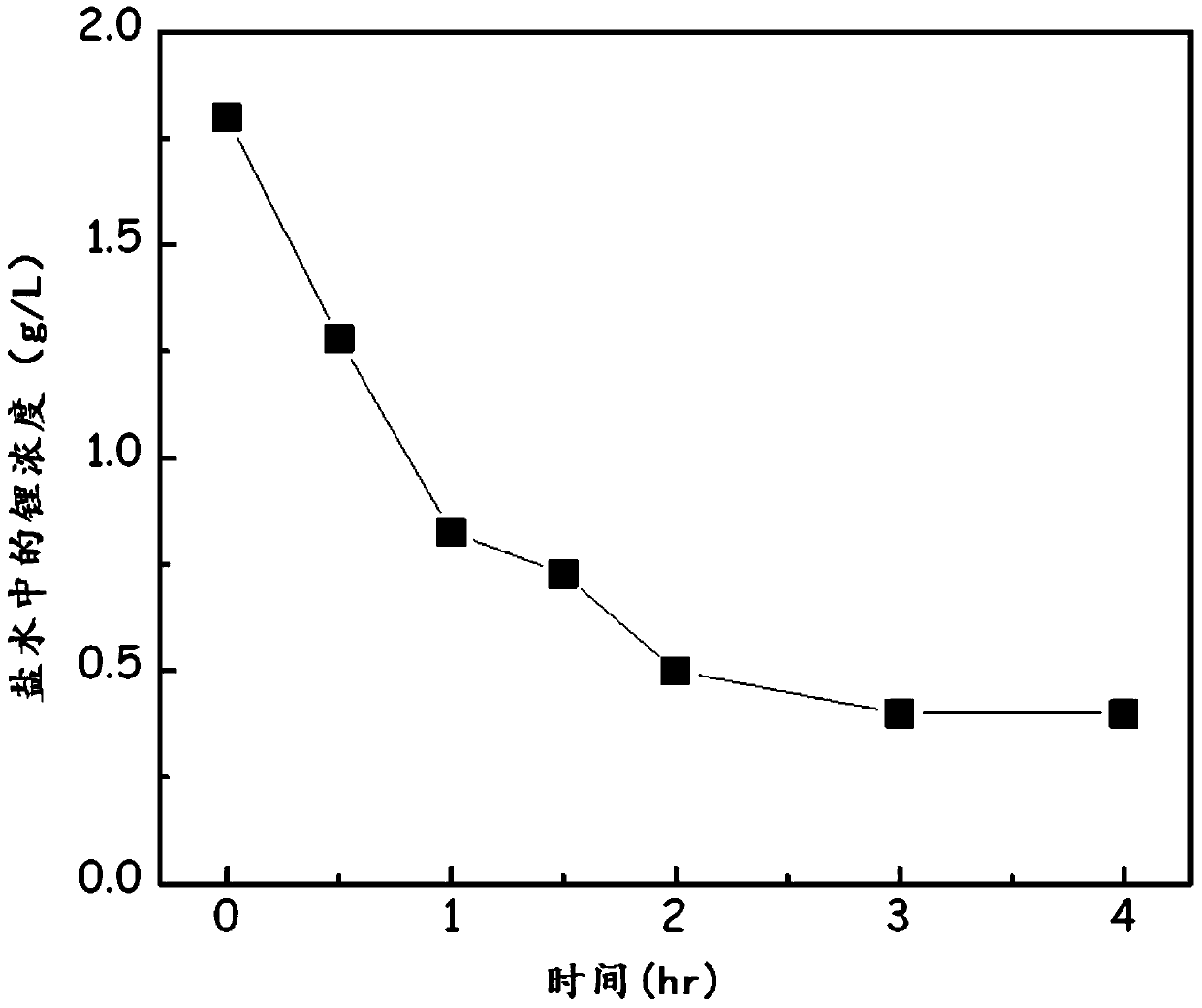

[0180] figure 2 Data showing the lithium concentration in the brine as a function of time after the addition of phosphoric acid.

[0181] Such as figure 2 As shown, the lithium concentration was initially 1.8g / L, and gradually decreased over time, and when the reaction time was 3 hours, the lithium concentration was 0.4g / L, and the lithium recovery rate was 77.7%.

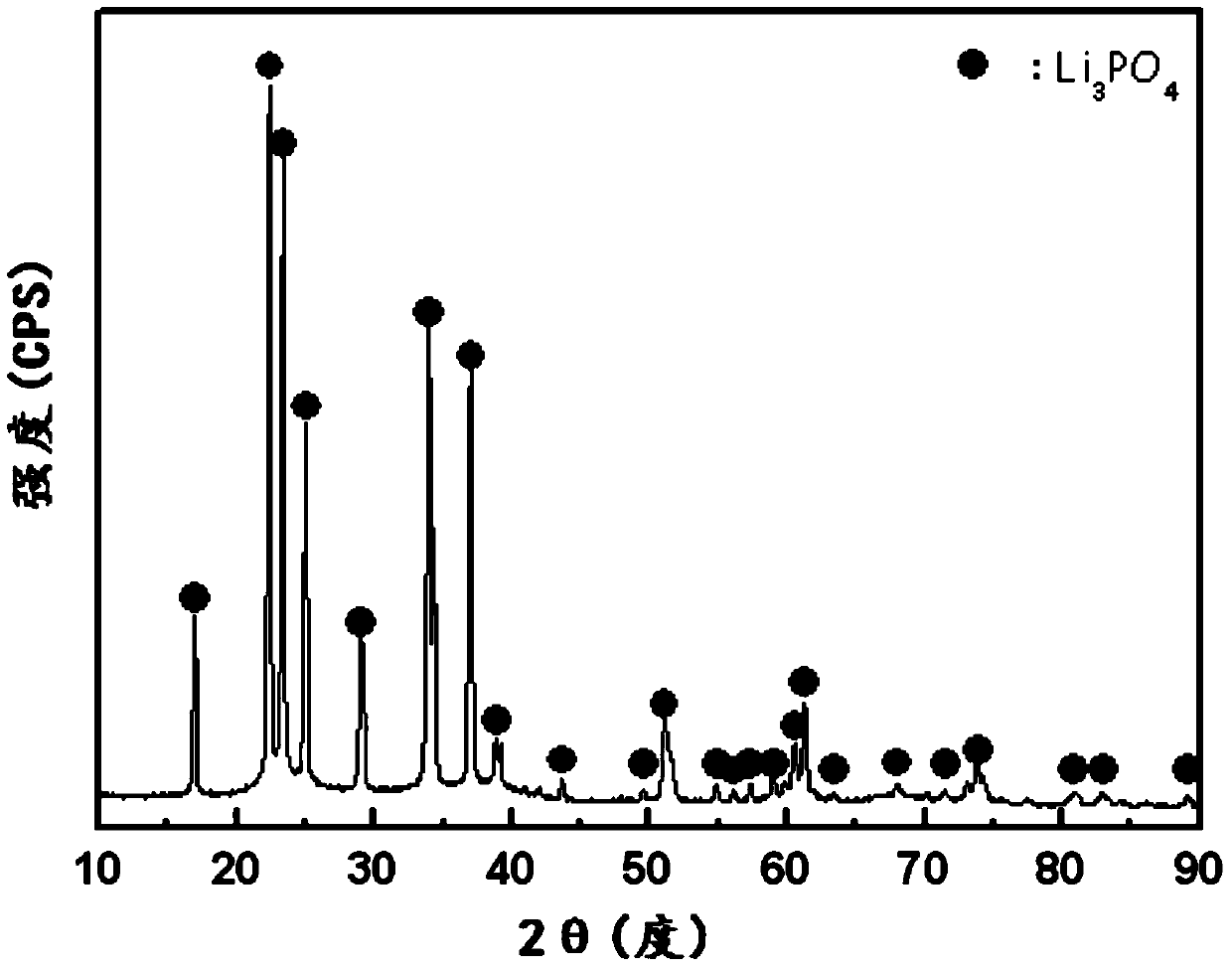

[0182] image 3 shows the mineral phase analysis results of the precipitate...

Embodiment 3

[0183] Example 3: Reconcentration of Filtration Solution and Extraction of Lithium Phosphate Using Nuclear Particles

[0184] The brine from which the lithium has been extracted is concentrated again to a range in which lithium is not precipitated. The main mineral phases of the precipitate are NaCl, KCl and NaK 3 (SO 4 ) 2 .

[0185] Table 3 below shows the composition of the filtered solution when the moisture evaporation rate is 60%.

[0186] [table 3]

[0187] project

Li

Na

K

SO 4

CO 3

Cl

Concentration(g / L)

0.877

143.1

74.6

21.0

67.9

156.5

[0188] To extract lithium from the solution, lithium phosphate was added as a seed to 1 equivalent of dissolved lithium, at which point no water-soluble phosphoric acid was added, and the lithium concentration at different times was subsequently measured.

[0189] Figure 4 The data showing the lithium concentration in the brine as a function of time a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com