Method of extracting lithium

A technology for extracting lithium and lithium solution, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve problems such as undeveloped, uneconomical, calcium carbonate sludge, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

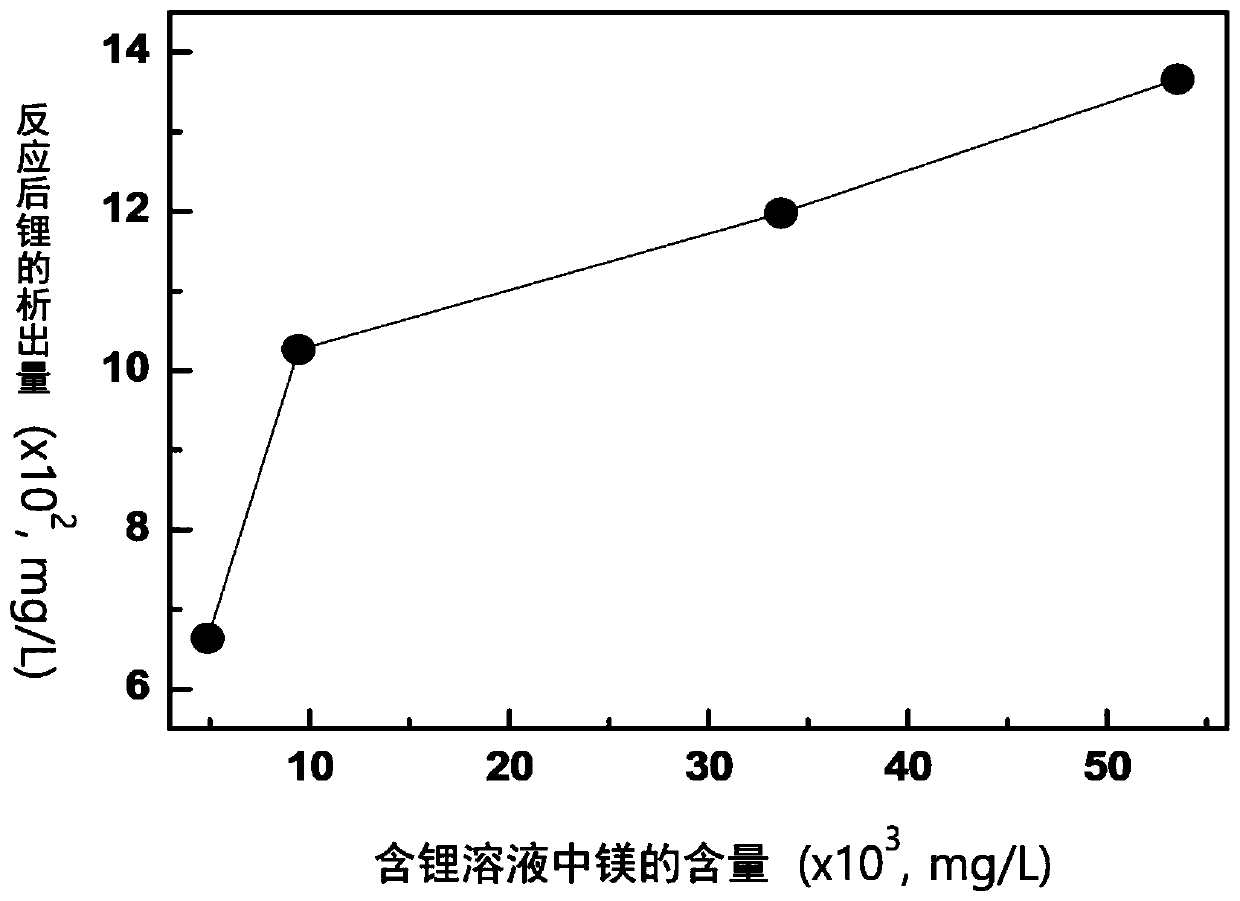

[0056] Add Na at a concentration of 23 g / L to a lithium-containing solution derived from brine in which lithium ions are dissolved at a concentration of about 3000 mg / L and magnesium ions are dissolved at a concentration of 9448 mg / L to 53543 mg / L. 3 PO 4 Thereafter, stirring was performed at normal temperature for 120 minutes to perform a reaction.

[0057] After the reaction was completed, the lithium-containing solution was filtered and the reaction precipitate was separated, then the remaining filtrate was extracted, and the concentrations of lithium, magnesium, calcium and strontium were measured, and the results are shown in Table 2.

[0058] [Table 2]

[0059]

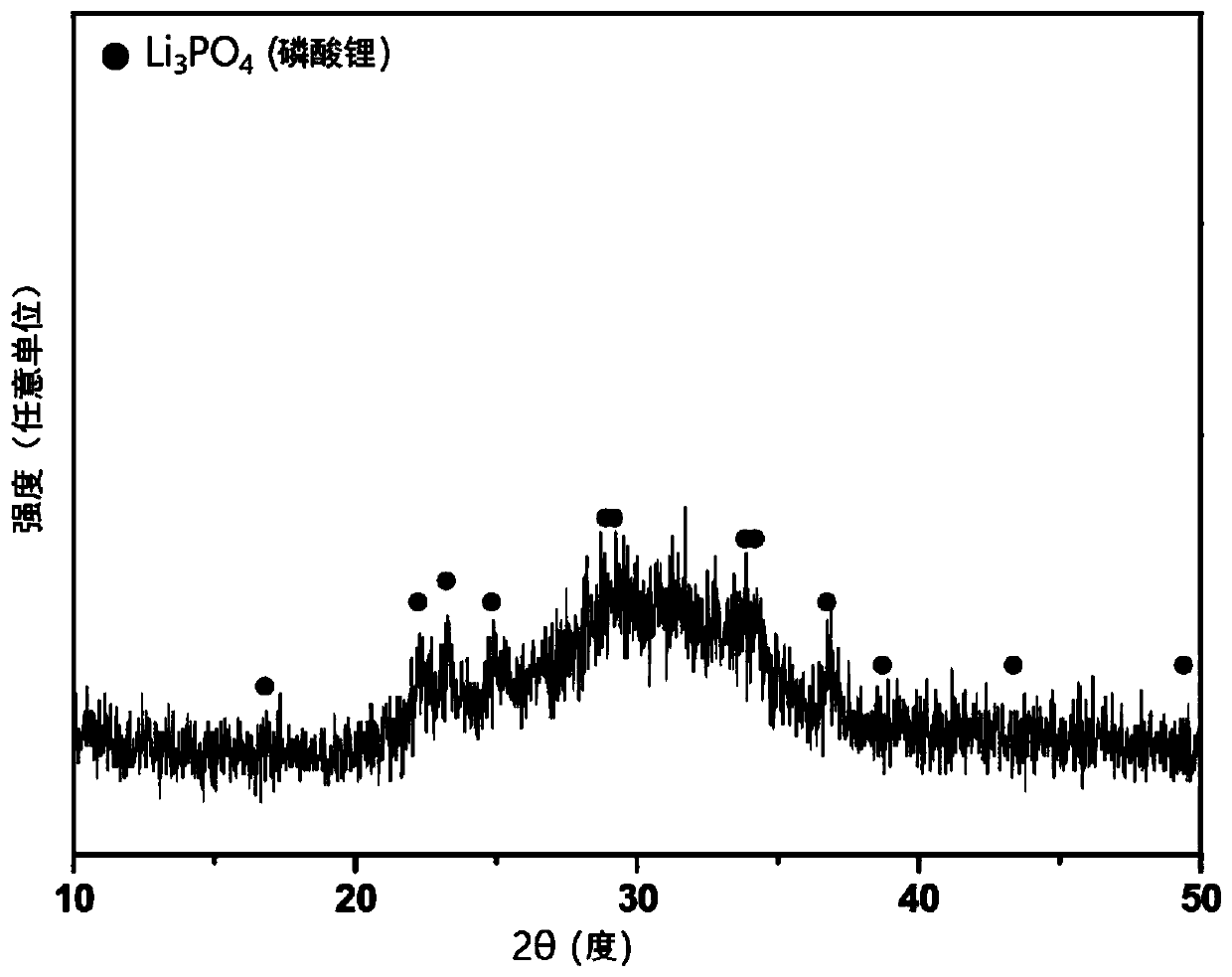

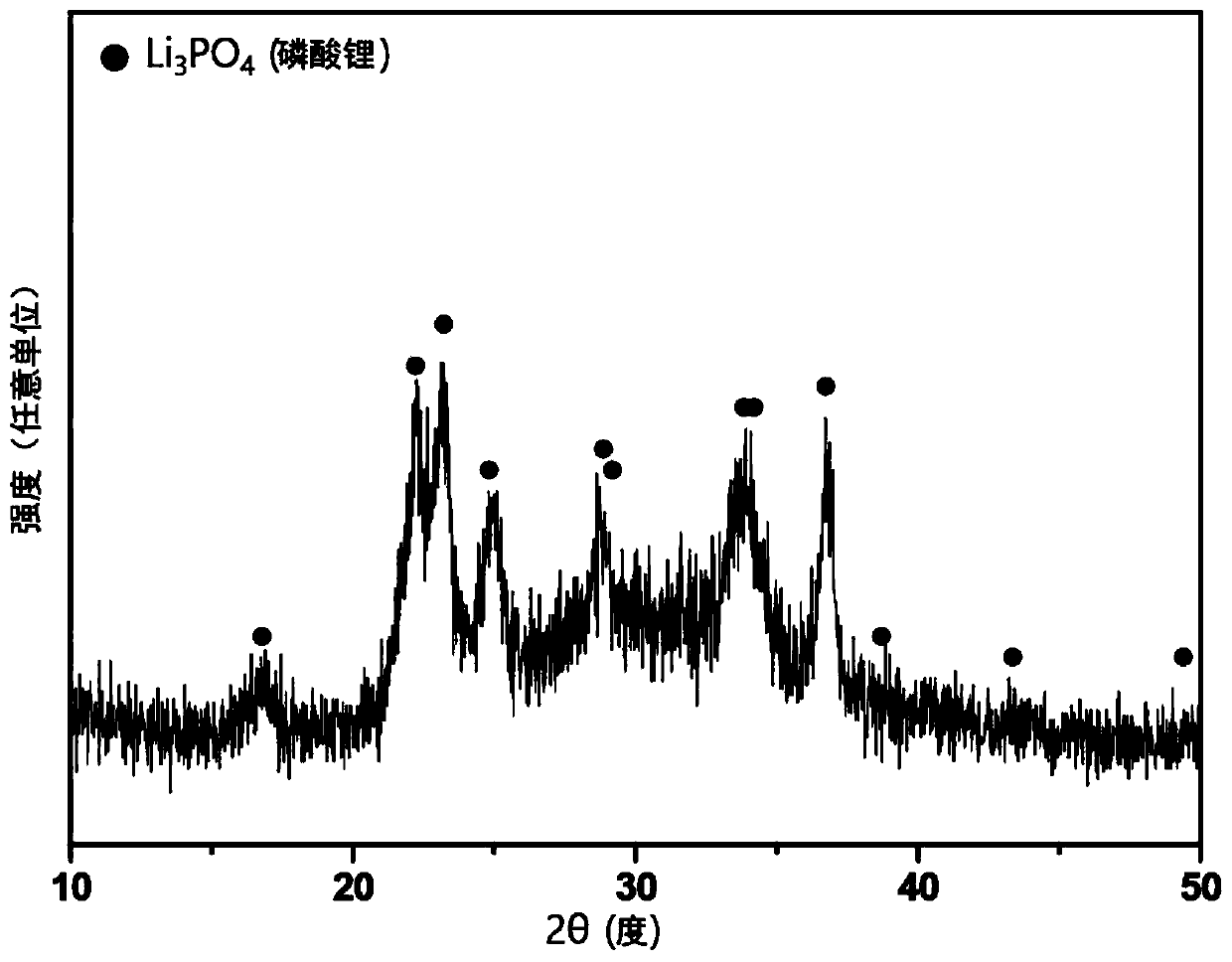

[0060] In addition, the reaction precipitate was dried at 60°C for 24 hours, and the mineral phase was analyzed by X-ray diffraction analyzer, and the results were shown in figure 2 middle.

[0061] As shown in Table 2, it can be seen that when a phosphorus supply material is added to a lithium-containing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com