Roof high-voltage box installation structure

A technology of installation structure and high-voltage box, which is applied in the direction of electrical components, substation/switch layout details, etc., can solve the problems affecting the electrical performance of high-voltage components, the impact of silicone rubber material hydrophobicity, and the impact on the operation safety of EMUs, so as to save manpower and Water source, reduce electrical discharge performance, and reduce the effect of cleaning times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

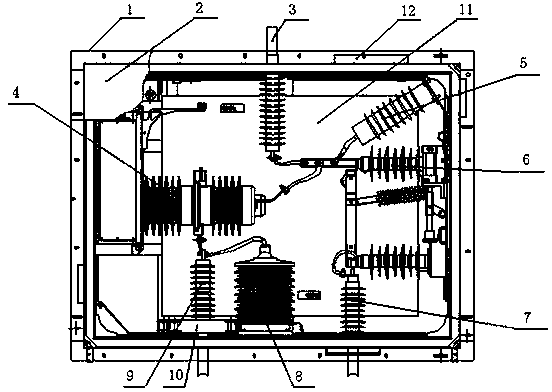

[0013] refer to figure 1 , figure 2 The high-voltage box 1 adopts a glass fiber reinforced plastic top cover 2, and the inner bottom surface of the high-voltage box is laid with GTO-3 laminated boards 11 to increase the electrical clearance between the high-voltage connection point and the ground of the box body. Avoid the impact of impurities in the FRP material on the electrical clearance, so that the FRP top cover becomes an insulating top cover; the vacuum main circuit breaker 4, voltage transformer 8, current transformer 10, isolation switch 6, lightning arrester 5, and three high-voltage The cable head and all components are installed on the side wall of the box body. After installation, ensure that the top cover is flush with the roof and reduce wind resistance at the same time. The high-voltage power supply of the EMU is introduced into the high-voltage box by the first high-voltage cable head 9 and divided into two paths: one path enters the voltage transformer;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com