Schottky diode and manufacturing method thereof

A technology of Schottky diode and manufacturing method, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of low forward turn-on voltage, small on-resistance, and high breakdown voltage, and achieve forward turn-on The effect of low voltage, low on-resistance and high breakdown voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

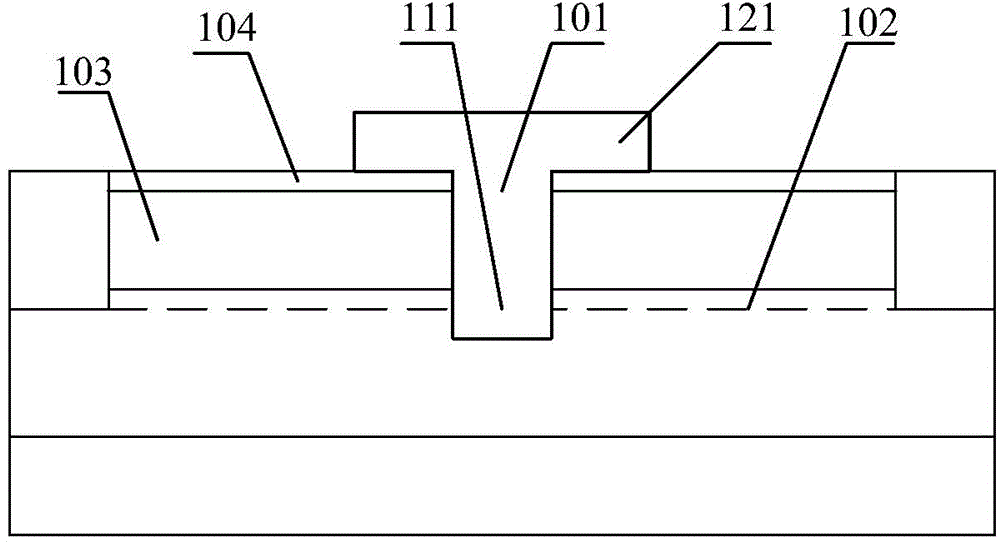

[0059] image 3 is a schematic cross-sectional view of the Schottky diode provided by Embodiment 1 of the present invention. Such as image 3 shown, the Schottky diode consists of:

[0060] Substrate 1. Among them, the material of the substrate 1 can be silicon carbide, silicon nitride, silicon, sapphire, aluminum nitride, gallium nitride, SOI (silicon-on-insulator, Silicon-On-Insulator) or other epitaxial growth III- Substrate material for Group V nitrides. Among them, SOI technology introduces a buried oxide layer between the top silicon and the back substrate.

[0061] Preferably, a nucleation layer 2 and a buffer layer 3 are sequentially deposited on the substrate 1 . Among them, the material of the nucleation layer 2 can be aluminum nitride, gallium nitride or other III-V nitrides; the material of the buffer layer 3 can be non-doped aluminum nitride, gallium nitride, aluminum gallium nitride or other III - Group V nitrides.

[0062] The first semiconductor layer 4 ...

Embodiment 2

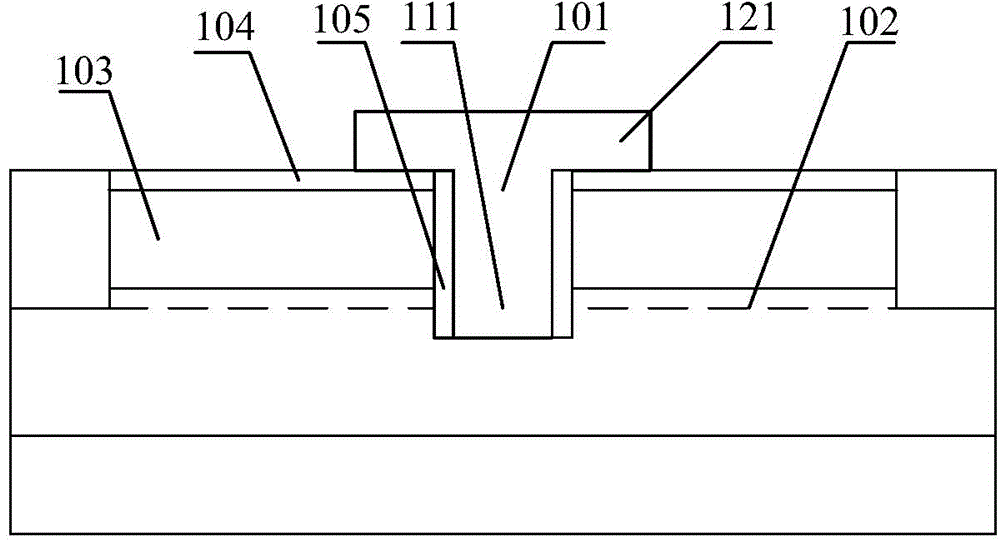

[0073] Figure 6 is a schematic cross-sectional view of the Schottky diode provided by Embodiment 2 of the present invention. Such as Figure 6 As shown, the difference from the Schottky diode provided in Embodiment 1 is that the high work function anode 10 of the Schottky diode provided in Embodiment 2 extends to the upper surface of the first passivation dielectric layer 7 to form an anode field board structure.

[0074] Compared with the Schottky diode provided in Embodiment 1 of the present invention, the Schottky diode provided in Embodiment 2 of the present invention has an anode field plate structure, which can further reduce the peak electric field at the edge of the anode, thereby reducing the Schottky junction Leakage.

Embodiment 3

[0076] Figure 7 is a schematic cross-sectional view of the Schottky diode provided in Embodiment 3 of the present invention. Such as Figure 7 As shown, the difference from the Schottky diode provided in Embodiment 2 is that the Schottky diode provided in Embodiment 3 also includes:

[0077] The field plate groove in the first passivation medium layer 7 is located under the high work function anode 10 , the bottom of the field plate groove is located on the upper surface of the second semiconductor layer 5 , and the high work function anode 10 covers the field plate groove. Wherein, the shape of the side surface of the field plate groove section is: straight line, broken line or arc; the angle between any side surface of the field plate groove and the bottom surface of the field plate groove is: right angle, obtuse angle or acute angle.

[0078] Compared with the Schottky diode provided in Embodiment 2 of the present invention, the anode structure of the Schottky diode prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com