Aging method of high specific volume aluminum electrolytic capacitor

A technology for aluminum electrolytic capacitors and capacitors, applied in electrolytic capacitors, capacitors, circuits, etc., can solve the problems of large leakage current of electrical performance indicators, inability to increase voltage, low production efficiency, etc., and achieve shortened aging time and short boost time. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

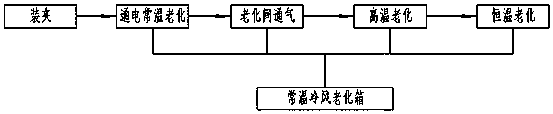

[0026] Such as figure 1 As shown, the high specific volume aluminum electrolytic capacitor aging method includes the following steps:

[0027] (1) Clamping: Fix the packaged core into the corresponding capacitor shell and seal it;

[0028] Aging at room temperature with power on: put the prepared capacitor into a cold air aging box, set the temperature at 22-28°C for 4-5 hours of aging at room temperature;

[0029] (2) Ventilate the aging room, ventilate the cold air aging box, provide 2 to 4 hours of ventilation, and then enter the next step;

[0030] (3) High-temperature aging: set the temperature of the cold air aging box at 80-100°C, and perform high-temperature aging for 3-6 hours;

[0031] (4) Aging at constant temperature. Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com