A melt magnetic spinning device and a method for preparing micro-nano fibers using the device

A technology of micro-nano fiber and magnetic spinning, which is applied in fiber processing, textile and papermaking, filament/wire forming, etc. It can solve problems such as complex structure, breakdown of heating circuit, hidden safety hazards, etc., and achieve uniform diameter distribution and arrangement Orderly and reduce the effect of potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Such as figure 1As shown, a melt magnetic spinning device includes a heatable feeding device that can control the feeding rate, a spinning nozzle 5, a nozzle driving mechanism and a spinning receiving device, and the feeding device is provided with a heating and melting polymer The heating part of the material, the spinning receiving device includes a horizontal collection disc 9, the center of the bottom of the collection disc 9 is connected to the output shaft of the brushless DC motor 10, and the brushless DC motor 10 is electrically connected to the power supply And the motor controller 11 that controls the motor speed, the upper surface of the collection disk 9 is symmetrically arranged with a plurality of vertical pillars with the central axis of the disk as the symmetrical axis, the vertical pillars are at least 3, and 1 of the vertical pillars It is a permanent magnet 7, and the rest are metal fine needles 8. The spinning nozzle 5 is horizontally arranged, and t...

Embodiment 2

[0031] Use the melt magnetic spinning device of embodiment 1 to prepare the method for micronano fiber, comprise the following steps:

[0032] (1) Mixing of materials: Fe with a mass ratio of 43:57 3 o 4 The magnetic nanoparticles and polycaprolactone are fully stirred and mixed, and the Fe 3 o 4 The diameter of the magnetic nanoparticles is 20 nanometers, and the molecular weight of the polycaprolactone is 100,000;

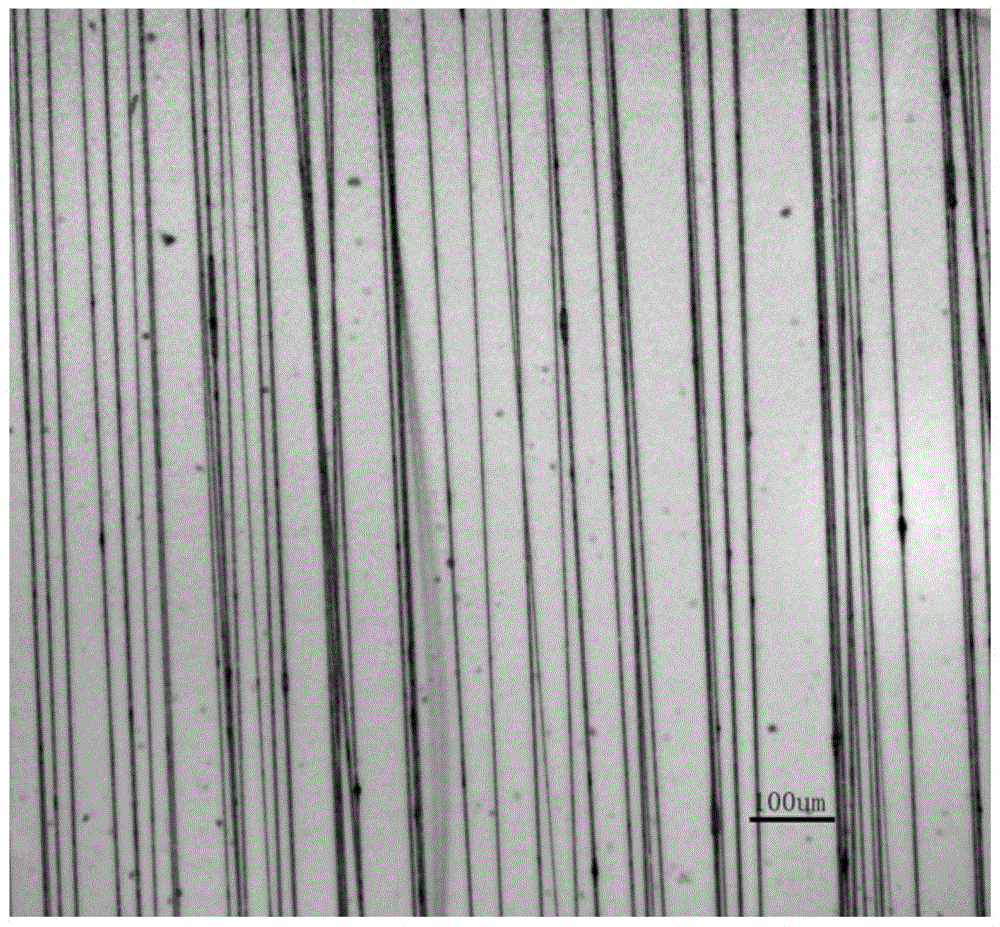

[0033] (2) Preparation of micro-nano fibers: the mixture obtained in step (1) is added from the hopper 2 into the single-screw extruder 1, and the single-screw extruder 1 is started. The single-screw diameter is 20 millimeters, and its aspect ratio is 25 , set the temperature of the feeding section to 80°C, the temperature of the plasticizing section to 85°C, the temperature of the homogenizing section to 90°C, and the screw speed to 50 rpm. Magnetic nanoparticles and polymers are heated in three stages Melted into a magnetic fluid spinning solution, mixed un...

Embodiment 3

[0035] Use the melt magnetic spinning device of embodiment 1 to prepare the method for micronano fiber, comprise the following steps:

[0036] (1) Material mixing: Fe with a mass ratio of 3:7 3 o 4 The magnetic nanoparticles and ethylene-vinyl acetate copolymer are fully stirred and mixed, and the Fe 3 o 4 The diameter of the magnetic nanoparticles is 20 nanometers, and the molecular weight of the ethylene-vinyl acetate copolymer is 2000;

[0037] (2) Preparation of micro-nano fibers: the mixture obtained in step (1) is added from the hopper 2 into the single-screw extruder 1, and the single-screw extruder 1 is started. The single-screw diameter is 20 millimeters, and its aspect ratio is 25 , set the temperature in the feeding section to 110°C, the temperature in the plasticizing section to 115°C, the temperature in the homogenizing section to 120°C, and the screw speed to 60 rpm. Magnetic nanoparticles and polymers are heated in three stages Melted into a magnetic fluid s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com