Aqueous-phase preparation method of bismuth sulfide/protein composite nanospheres

A protein composite and aqueous phase preparation technology, which is applied in the field of aqueous phase preparation of bismuth sulfide/protein composite nanospheres, can solve the problems of unstable product shape, unfavorable later application, easy agglomeration into large pieces, etc., and achieve short preparation cycle , easy to implement, and simple experimental equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

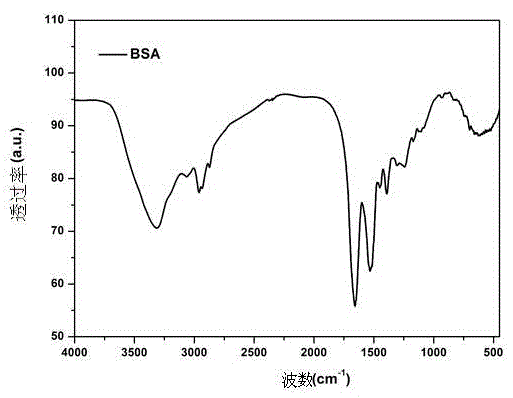

[0027] The first step: add 2.5 mmol of mannitol to 25 mL (10 mg / mL) aqueous solution of bovine serum albumin. The purity of the bovine serum albumin is >98% and the molecular weight is 68000. After stirring and dissolving at room temperature, add 1 mmol of bismuth nitrate pentahydrate particles, stirring and dissolving for 10 min at room temperature to form a mixed solution containing bismuth ions and protein;

[0028] The second step: 5 mL (300 mmol / L) thioacetamide solution was slowly added dropwise to the mixture of bismuth ion protein, and stirred at room temperature for 5 min to form a mixture of bismuth-sulfur bovine serum albumin;

[0029] The third step: put the bismuth-sulfur bovine serum albumin mixture in a 35 ℃ water bath and heat for 2 h, and then centrifuge the black solid obtained by centrifugation. After vacuum drying for 12 h, bismuth sulfide / protein composite nanospheres were prepared.

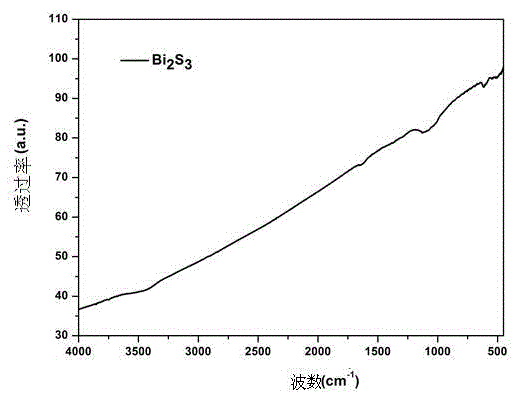

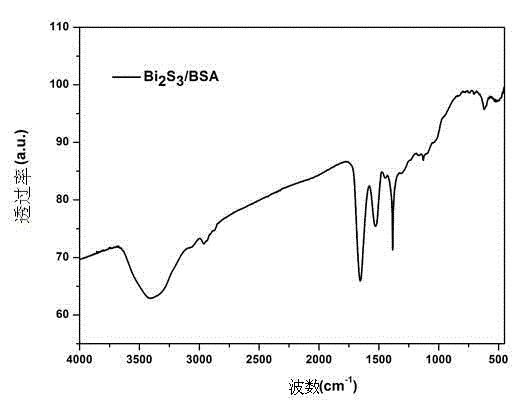

[0030] The experimental results show that the obtained bismuth sulfide / ...

Embodiment 2

[0032] Step 1: Add 1 mmol of bismuth nitrate pentahydrate particles to 25 mL (10 mg / mL) bovine serum albumin aqueous solution, and stir and dissolve for 10 min at room temperature;

[0033] The second step: 5 mL (300 mmol / L) of thioacetamide solution was slowly added dropwise to the above mixed solution, and stirred at room temperature for 5 min to form a bismuth-sulfur bovine serum albumin mixed solution.

[0034] The experimental results show that in the absence of mannitol, the bismuth ion is easily hydrolyzed into a white solid insoluble matter, resulting in the reaction not continuing normally.

Embodiment 3

[0036] Step 1: Add 2.5 mmol of mannitol to 25 mL of deionized water, stir and dissolve at room temperature, add 1 mmol of bismuth nitrate pentahydrate particles, stir and dissolve at room temperature for 10 min to form a solution containing bismuth ions;

[0037] The second step: slowly drop 5 mL (300 mmol / L) thioacetamide solution into the solution containing bismuth ions, and stir at room temperature for 5 min to form a bismuth-sulfur mixed solution;

[0038] The third step: put the bismuth-sulfur mixture in a water bath at 35°C for 2 h, and then perform centrifugation. The black solids obtained by centrifugation were washed three times with deionized water and ethanol, respectively, and then vacuum-dried at 30°C. 12 h, bismuth sulfide nanomaterials were prepared.

[0039] The experimental results show that bismuth sulfide nanomaterials can still be synthesized without bovine serum albumin, but the obtained products have different sizes, larger particle sizes, poor dispersio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com