Solid acid catalyst for glycerinum esterification and aldolization, and preparation method therefor

A technology of solid acid catalyst and acetal reaction, which is applied in the direction of chemical instruments and methods, preparation of organic compounds, physical/chemical process catalysts, etc., to achieve the effects of simple preparation, simple filtration and recovery, and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

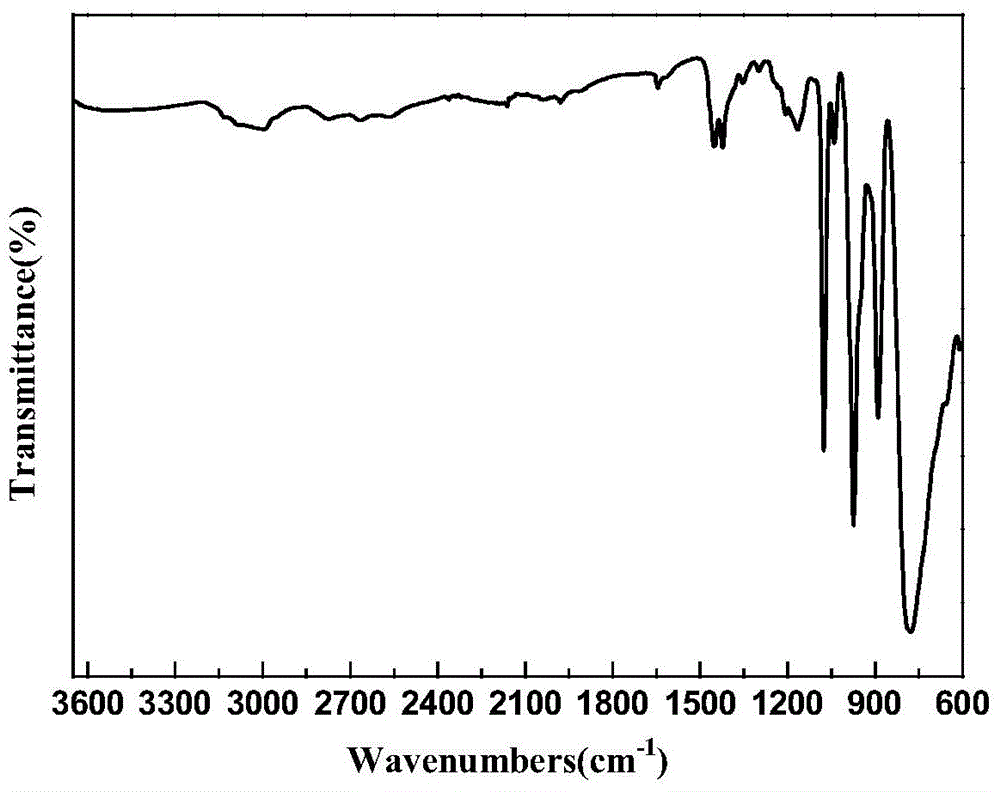

Image

Examples

Embodiment 1

[0015] -SO 3 Functionalized Triallylamine TAM-SO 3 Preparation: In a round-bottomed flask, add 0.1mol of triallylamine and 0.1mol of 1,3-propane sultone into 30mL of toluene solvent, stir at 100°C for 24h, and separate out the lower layer of yellow oil The product was washed three times with ethanol and dried under vacuum at 60 °C for 10 h to obtain TAM-SO 3 .

[0016] Polymeric solid acid catalyst Poly(TAM-SO 3 HPW) preparation: the above 0.05mol TAM-SO 3 Add to 30mL methanol solvent, add 0.1g azobisisobutyronitrile AIBN, then stir at 70°C for 24h, remove the solvent by rotary evaporation, wash the product three times with ethyl acetate, and dry it under vacuum at 60-90°C for 10h to obtain Poly (TAM-SO 3 ), 0.54g Poly(TAM-SO 3 ) and 2g phosphotungstic acid (H 3 PW 12 o 40 ) was added to 50mL of deionized water, stirred at room temperature for 12h, filtered to remove the solvent, and the solid product was vacuum-dried at 60°C for 10h to obtain a polymeric solid acid c...

Embodiment 2

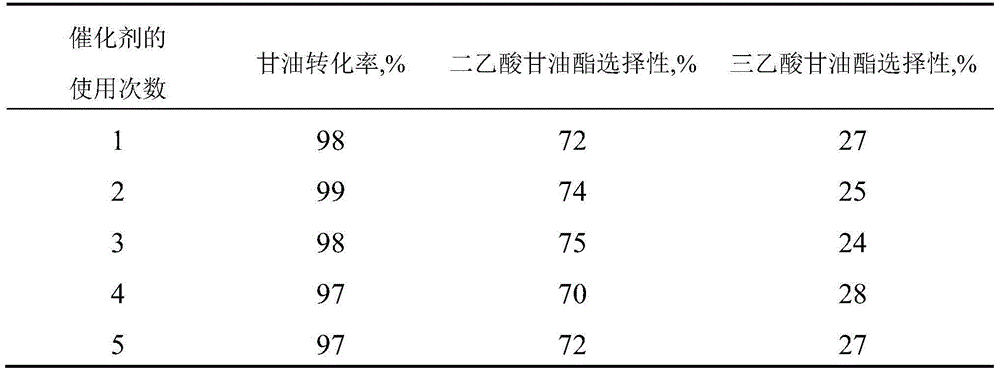

[0018] In a 100mL round bottom flask, add 0.1mol glycerol, 0.6mol acetic acid and 30mL toluene, then add 0.6g of solid acid catalyst Poly(TAM-SO 3 HPW), at a reaction temperature of 120° C., reflux to separate water, and stirred for 2 hours. Through chromatographic analysis, the conversion rate of glycerin was 98%, the selectivity of diacetin was 72, and the selectivity of triacetin was 27%.

Embodiment 3

[0020] In a 100mL round bottom flask, add 0.1mol glycerin and 0.12mol benzaldehyde, then add 0.2g solid acid catalyst Poly(TAM-SO 3 HPW), at a reaction temperature of 30°C, stirred and reacted for 2 hours, through chromatographic analysis, the conversion rate of glycerol was 92%, and the acetal product selectivity of 1,3-dioxolane was 59%, and 1,3-dioxolane The acetal product selectivity of the hexacyclic ring was 38%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com