Calcination crystallization method of nanometer TiO2/porous mineral composite material

A technology of porous minerals and composite materials, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of difficult large-scale production, unstable product quality, long calcination time, etc., to save Effects of time and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

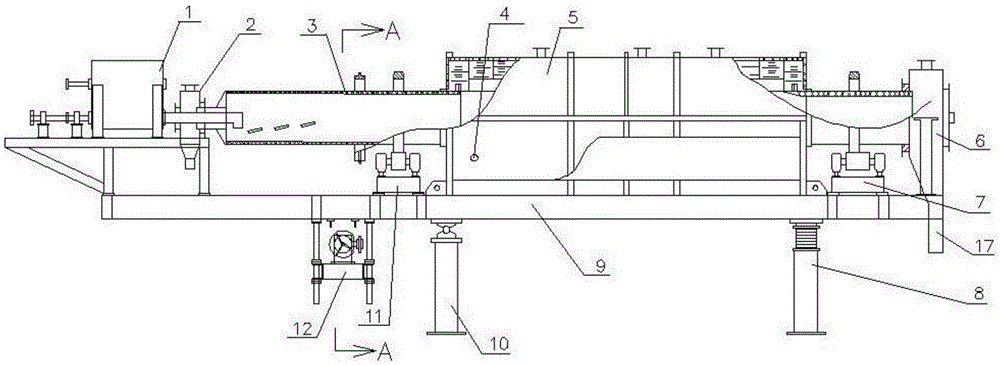

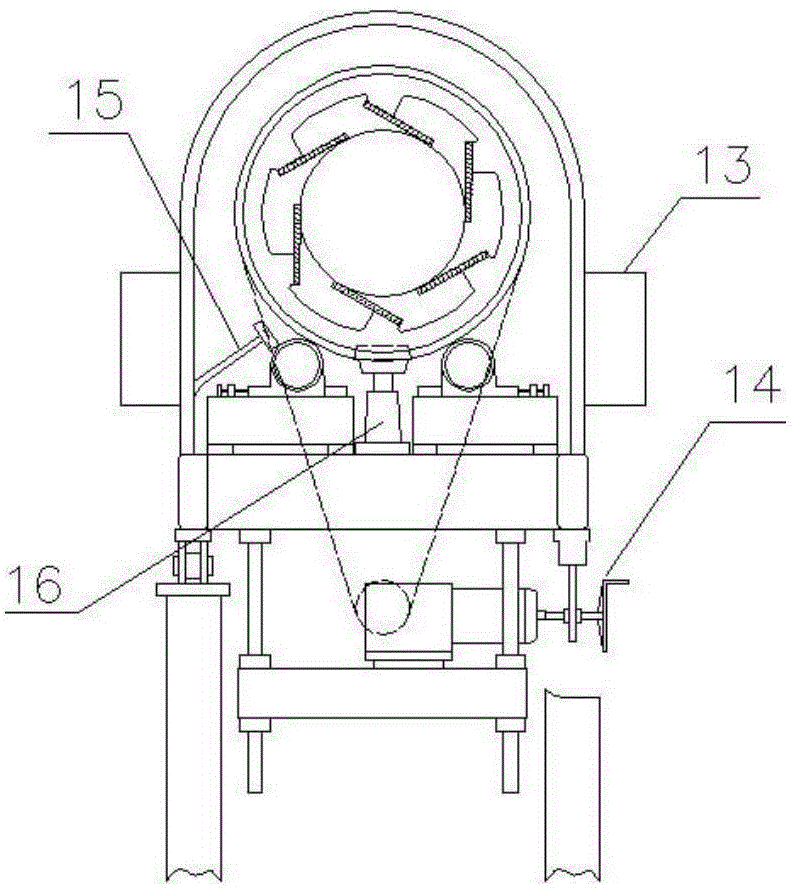

[0016] Example 1: Φ550×9600mm cylindrical rotary calciner, cylinder diameter 550mm, length 9600mm, cylinder wall thickness 12mm, cylinder main material is 309S; electric heating power 75kW; rotary kiln inclination: 0°~2° range Adjustable; cylinder speed: 1 ~ 3r / min range adjustable; main motor transmission power: 2.2kW, screw feeding, power of dehumidification fan: 2.0kW; support method: second gear support roller; transmission method: chain transmission , equipped with a manual device; the temperature rise of the outer surface of the furnace is <45°C; temperature control method: automatic temperature control by intelligent instruments.

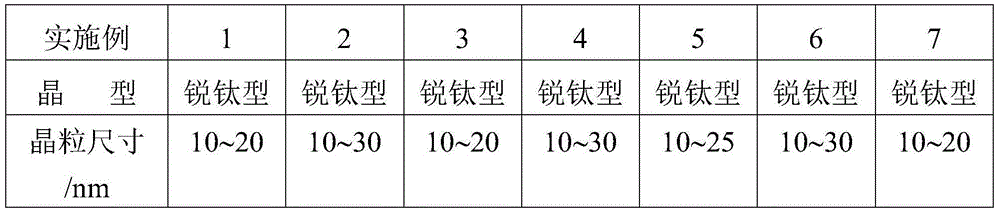

[0017] Diatomaceous earth loaded nano-TiO after loading is completed and dried 2 Composite powder material, bulk density 0.32g / ml, water content: adsorption water ≤ 5%, structural water 15.5%; the material stays in the 650°C heating zone for 1h from the feed, and 1.5h in the 650°C high temperature zone. Stay in the cooling zone at 650-80°C f...

Embodiment 2

[0018] Embodiment 2: adopt the cylinder type rotary calciner of the same specification as embodiment 1.

[0019] After the loading is completed and dried, the nano-titanium dioxide composite powder material loaded with diatomite filter aid has a bulk density of 0.35g / ml and a water content of the material: adsorption water ≤ 4%, structural water 15.0%; the material is heated from feeding to 600°C Zone residence time 1h, residence time in 600°C high temperature zone for 2h, stay in 600-80°C cooling zone for 0.75h; accumulative calcination time is 3.75h; continuous feed and output, feed rate 21kg / h; calcined and crystallized finished product The output is 17kg / h. Calcined and crystallized nano-TiO 2 Nano-TiO / Diatomite Filter Aid Composite 2 The crystal forms and grain sizes are listed in Table 1.

Embodiment 3

[0020] Embodiment 3: adopt the cylinder type rotary calciner of the same specification as embodiment 1.

[0021] Attapulgite-loaded nano-titanium dioxide composite powder material after the loading is completed and dried, the bulk density is 0.40g / ml, the water content of the material: adsorption water ≤ 5%, structural water 15.0%; the residence time of the material from feeding to 600°C heating zone 1h, stay in the high temperature zone at 600°C for 2h, stay in the cooling zone at 600-80°C for 0.75h; the cumulative calcination time is 3.75h; continuous feeding and output, the feeding amount is 22kg / h; the output of calcined and crystallized products is 18kg / h h. Calcined and crystallized nano-TiO 2 Nano-TiO / Attapulgite Composite Materials 2 The crystal forms and grain sizes are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com