O/W nano-emulsion and low-energy-consumption preparation method thereof

A technology of nanoemulsion and liquid paraffin, applied in mixing methods, chemical instruments and methods, dissolution, etc., can solve problems such as heat loss, expensive equipment, high energy, etc., and achieve small particle size, narrow distribution, and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

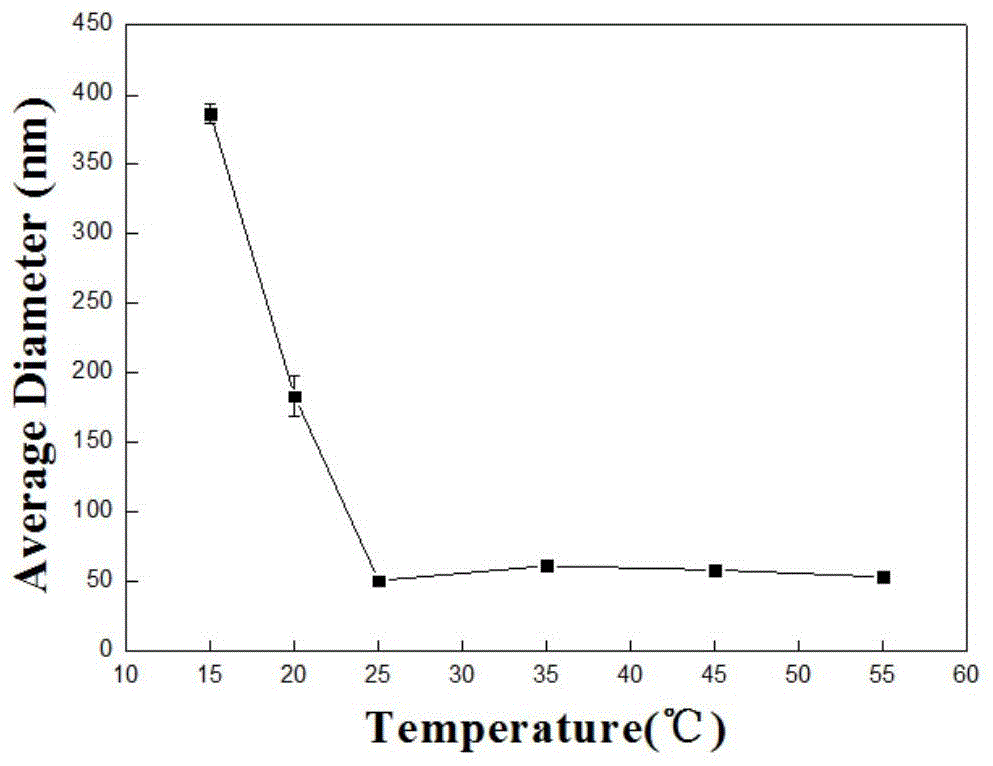

[0021] In 100 parts by weight, get 3 parts of nonionic surfactant lauryl polytetraoxyethylene ether, 7 parts of liquid paraffin, be placed in reactor, stir 5min with 600rpm speed on magnetic stirrer, at this stirring speed Add pure water drop by drop, the dropping rate is controlled at 0.1mL / min, add 90 parts of pure water and pour the prepared nanoemulsion into a straight cylinder bottle for later use. The experimental temperatures were 15°C, 20°C, 25°C, 35°C, 45°C, and 55°C, respectively.

[0022] Investigate the particle diameter of the prepared nanoemulsion as follows:

[0023] The particle size distribution of the nanoemulsion was determined with (ZEN3690, Malvern Instrument Ltd). The laser particle size nanometer instrument uses a He-Ne laser light source with a wavelength of 632.8nm. During the test, the scattering angle is 90°, the accumulation time is 240-300s, the scanning is repeated for more than 3 times, and the measurement temperature is 25°C. Dilute the emulsi...

Embodiment 2

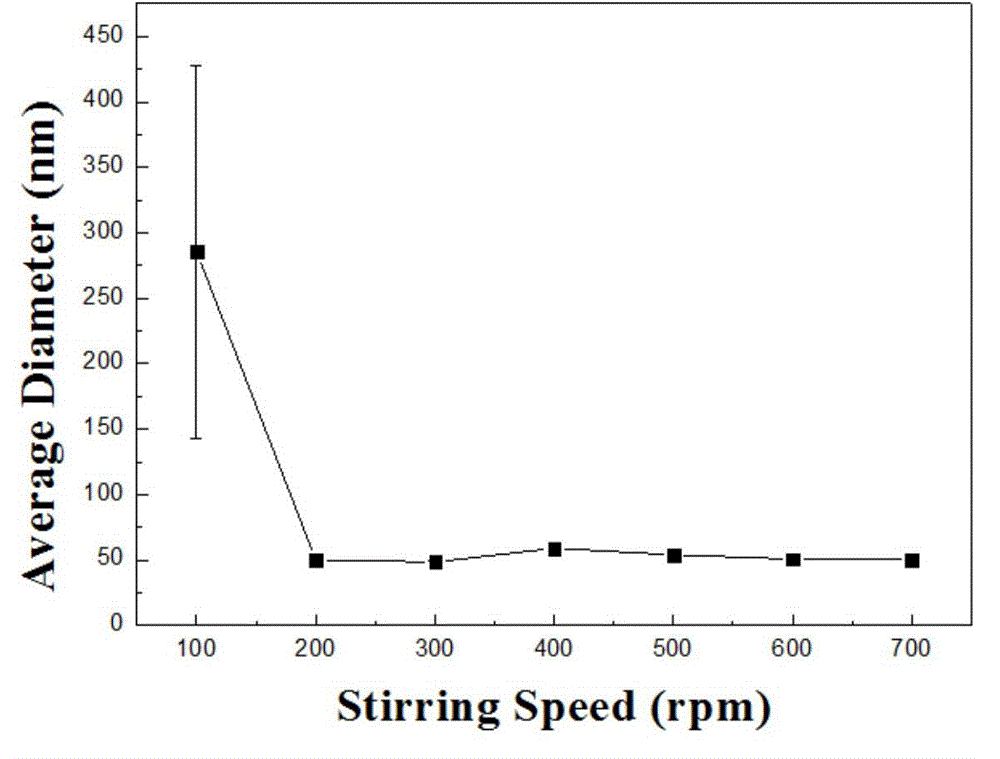

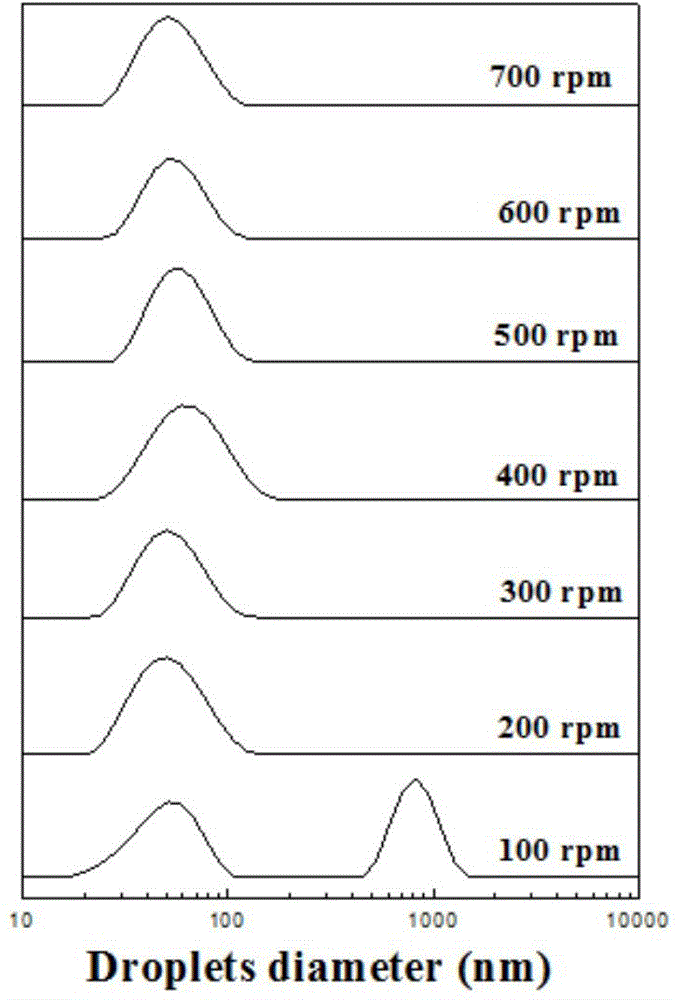

[0025] At 25°C, in terms of 100 parts by weight, take 3 parts of nonionic surfactant lauryl polytetraoxyethylene ether, 7 parts of liquid paraffin, put them in the reactor and stir on a magnetic stirrer for 5 minutes, and control the stirring rate respectively 100rpm, 200rpm, 300rpm, 400rpm, 500rpm, 600rpm, 700rpm, and add pure water drop by drop at this stirring rate, the dropping speed is controlled at 0.1mL / min, add 90 parts of pure water, pour the prepared nanoemulsion Put it in a straight bottle for later use.

[0026] Detect by the method described in embodiment one, its result is as follows figure 2 and 3 as shown, figure 2 It shows that the particle size of the prepared nanoemulsion is larger at a low stirring rate of 100rpm, and the particle size of the prepared nanoemulsion is basically the same at a stirring rate of 200rpm-700rpm. image 3 It shows that in the case of stirring rate of 100rpm, the prepared emulsion contains a part of nanoemulsion droplets of abo...

Embodiment 3

[0028] At 25°C, control the ratio of nonionic surfactant and oil phase to 1:9, 2:8, 3:7, 4:6, 5:5, 6:4, 3:7, 2:8, Stir 5min with 600rpm speed on the magnetic stirrer, dropwise add pure water (water content is respectively 70wt%, 80wt%, 90wt%) under this stirring speed, drop rate is controlled at 0.1mL / min, the nanoemulsion that makes Pour the liquid into a straight bottle for later use.

[0029] Detect by the method described in embodiment one, its result is as follows Figure 4 as shown, Figure 4 It shows that with the increase of the surfactant content, the particle size first decreases and then increases, and the water content has little effect on the particle size.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com