Photoelectric composite cable

A technology of photoelectric composite cable and optical cable, which is applied in the field of communication, can solve the problems of high complexity of single optical fiber processing, large size of connection, and easy failure, and achieve the effect of avoiding wiring difficulties, improving mechanical properties, and improving tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

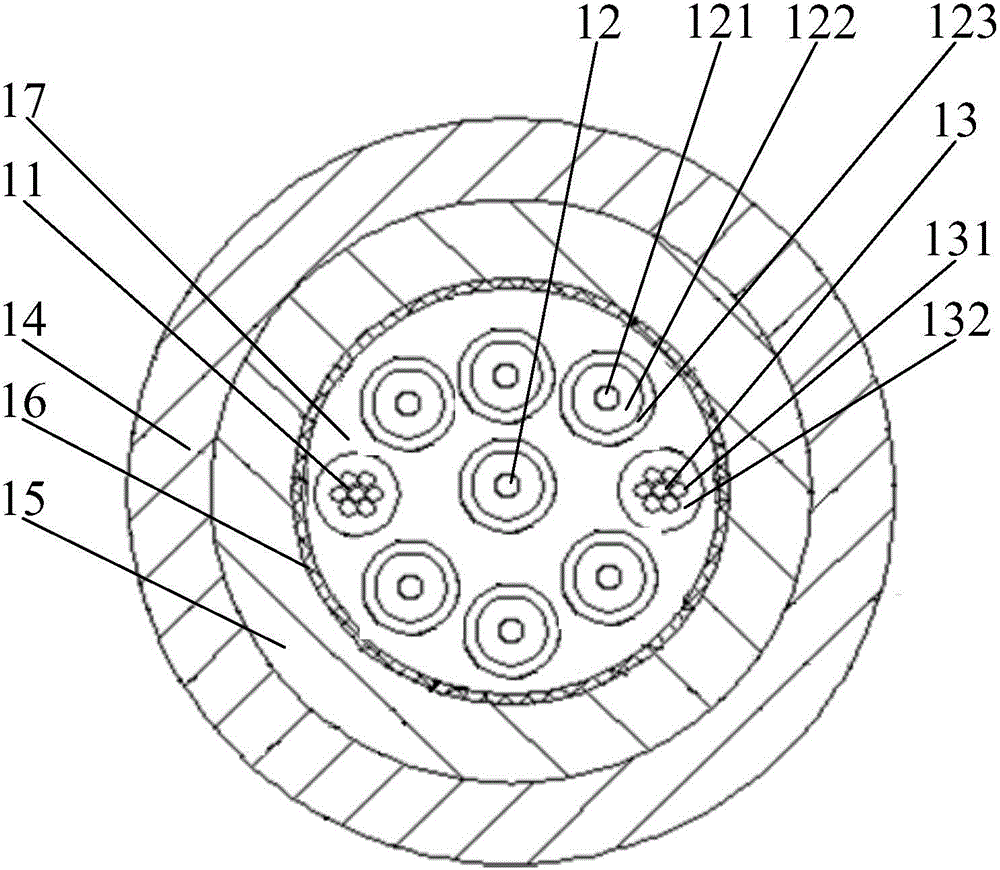

Embodiment 1

[0029] Please refer to the attached figure 1 , figure 1 It is a schematic structural diagram of the photoelectric composite cable provided by Embodiment 1 of the present invention. The photoelectric composite cable provided by Embodiment 1 of the present invention includes a fire wire cable 13, a ground wire cable 11, an optical cable 12 and at least two layers of plastic sheaths, preferably, such as figure 1 The inner plastic sheath 15 and the outer plastic sheath 14 are shown. Wherein, the inner plastic sheath 15 is coated on the cable bundle formed by the fire wire cable 13, the ground cable 11 and the optical cable 12, and the outer plastic sheath 14 is coated on the inner plastic sheath 15 , the outer plastic sheath 14 and the inner plastic sheath 15 are detachably connected, that is, the two can be peeled off.

[0030] figure 1 The middle sealing plastic sheath has two layers of inner and outer layers. In order to improve the protection performance of the cables (inc...

Embodiment 2

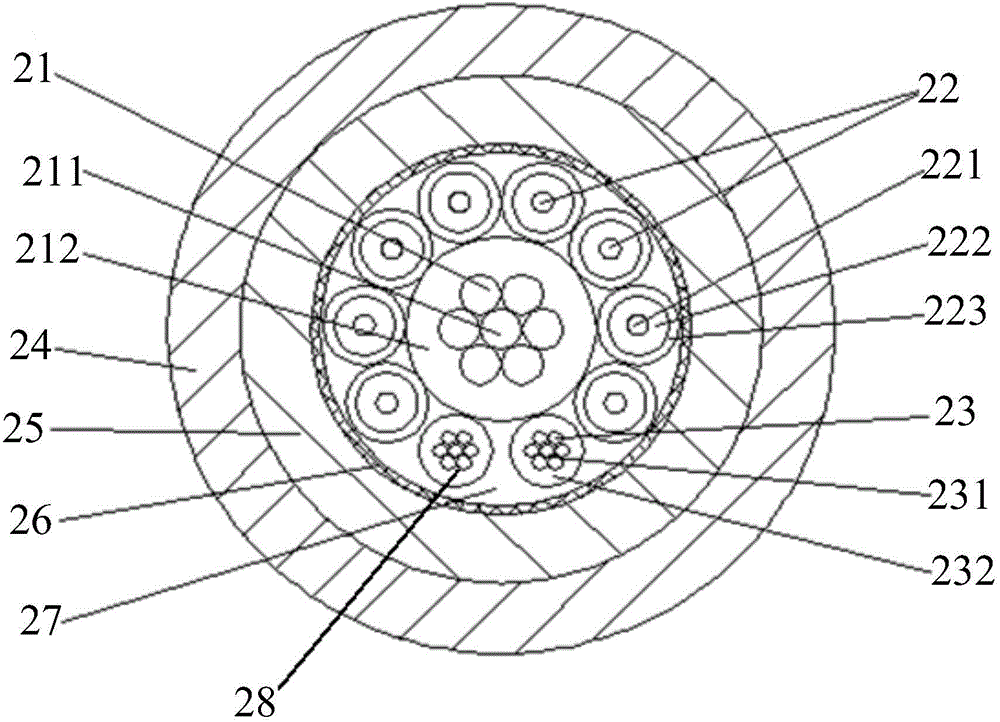

[0039] During the wiring process, the photoelectric composite cable is usually subjected to a large pulling force, which will damage the photoelectric composite cable to a certain extent. To solve this problem, please refer to the attached figure 2 , figure 2 It is a schematic structural diagram of the photoelectric composite cable provided by Embodiment 2 of the present invention.

[0040] The photoelectric composite cable provided by Embodiment 2 of the present invention includes a fire wire cable 23, a ground wire cable 28, an optical cable 22, a reinforcing rib 21 and at least two layers of plastic-molded sheaths. preferred, such as figure 2 The inner plastic sheath 25 and the outer plastic sheath 24 are shown. Wherein, the inner plastic sheath 25 is coated on the cable bundle formed by the fire wire cable 23 , the ground cable 28 and the optical cable 22 , and the outer plastic sheath 24 is coated on the inner plastic sheath 25 , the outer plastic sheath 24 and the ...

Embodiment 3

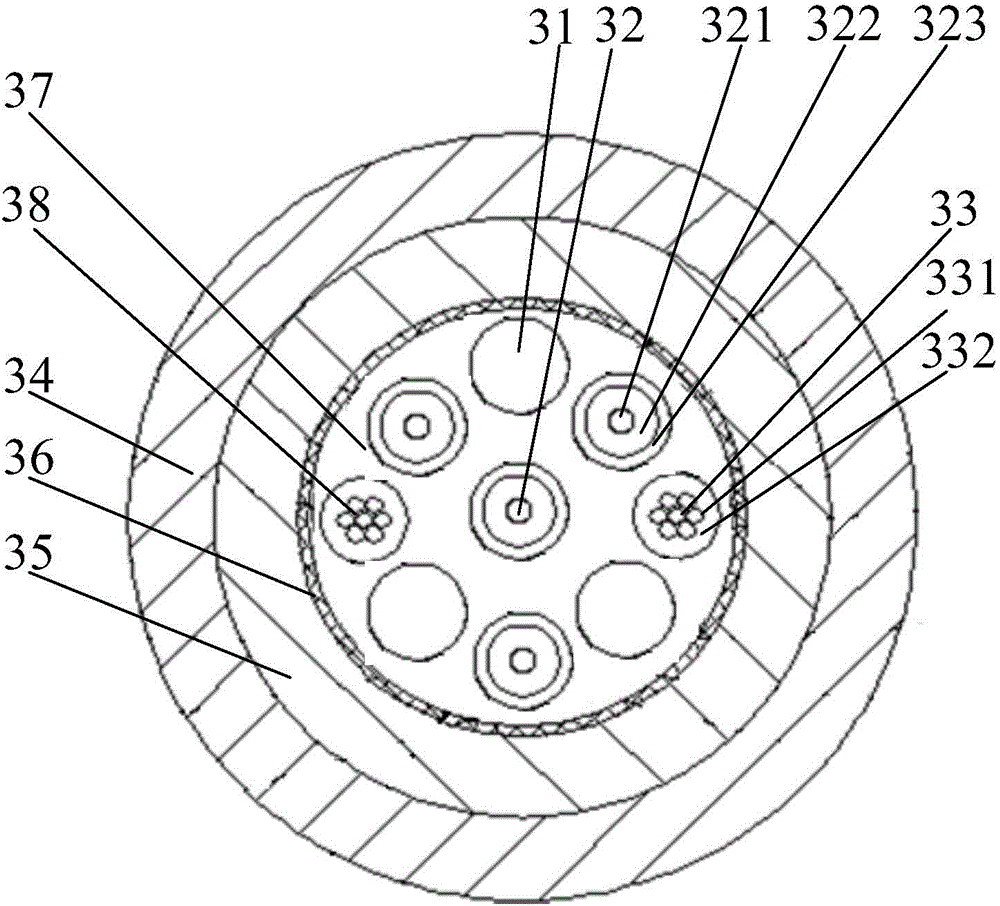

[0051] When the number of optical cables is small (such as one), the reinforcing ribs arranged in the center of the photoelectric composite cable are not enough to fill the gaps in the photoelectric composite cable, which will affect the mechanical properties of the photoelectric composite cable and easily lead to stress concentration. To solve this problem, please refer to the attached image 3 , image 3 It is a schematic structural diagram of the photoelectric composite cable provided by Embodiment 3 of the present invention.

[0052] The photoelectric composite cable provided in the third embodiment includes: a live wire cable 33 , a ground wire cable 38 , an optical cable 32 , at least two layers of plastic-molded sheaths, and a plurality of reinforcing ropes 31 located in the innermost layer of the plastic-molded sheath. preferred, such as image 3 The plastic-sealed sheath shown has two layers, the inner-layer plastic-sealed sheath 35 and the outer-layer plastic-seale...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com