Flexible externally toothed gear for strain wave gearing and method for manufacturing same

A technology of wave gear device and manufacturing method, which is applied in the directions of gear transmission device, transmission device, manufacturing tool, etc., to achieve the effects of improving the fatigue resistance of the bottom of the tooth, improving the wear condition of the tooth surface, and improving the hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

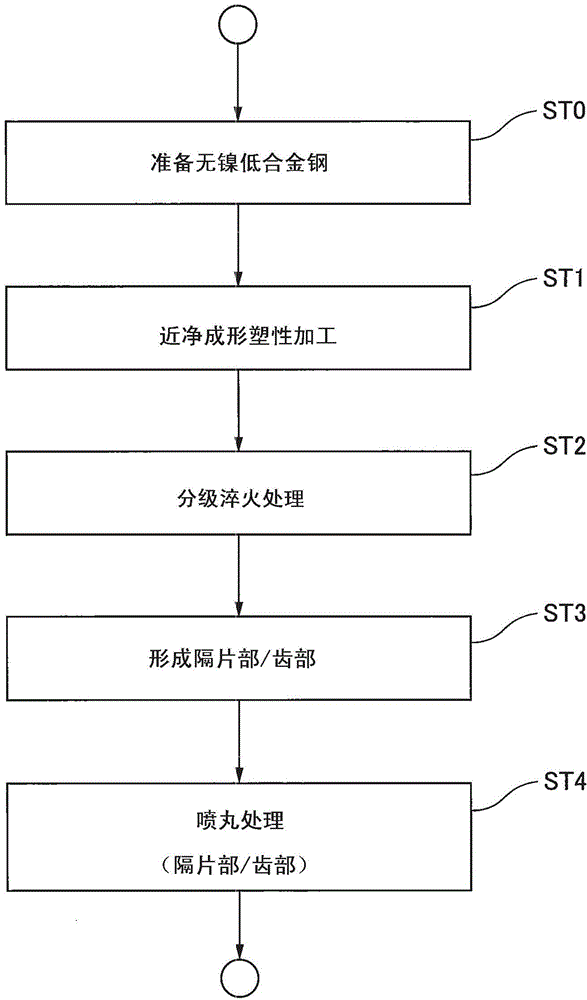

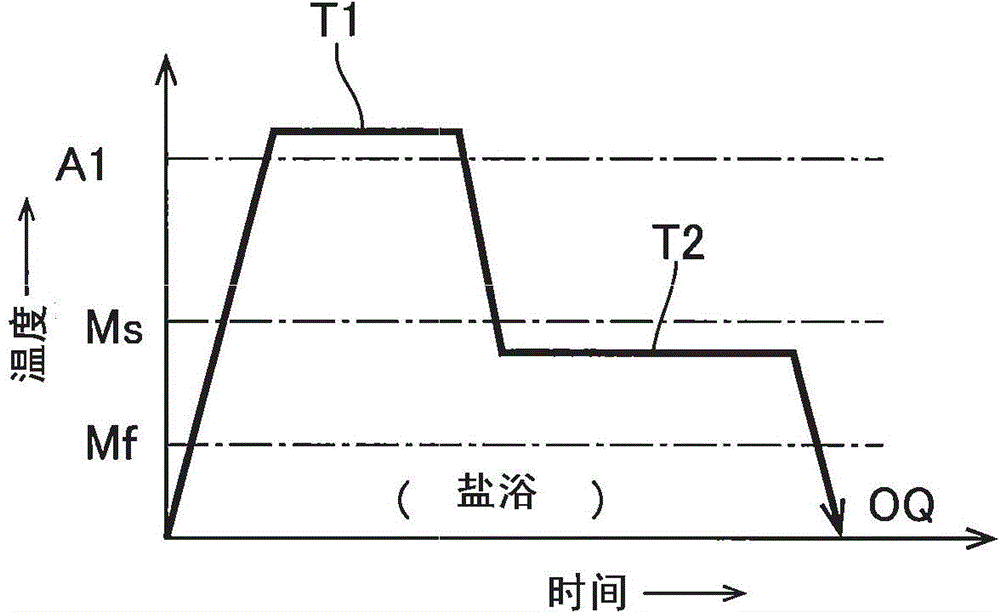

[0028] Hereinafter, a method of manufacturing a flexible externally toothed gear to which a wave gear device according to the present invention is applied will be described with reference to the drawings.

[0029] (Flexible External Gears)

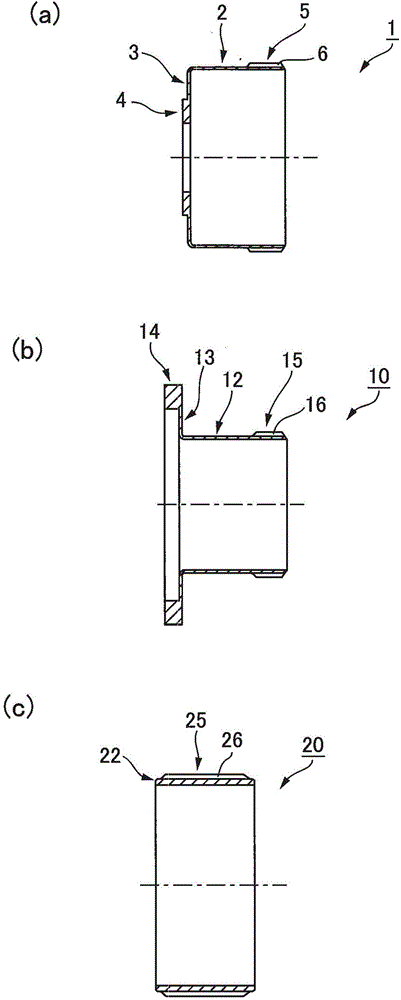

[0030] First, refer to figure 1 The flexible external gear of the wave gear device will be described. Such as figure 1 As shown in (a), the cup-shaped flexible externally toothed gear 1 includes: a thin-walled cylindrical body part 2 capable of bending in the radial direction; A thin-walled spacer part 3 that extends radially inward and can be flexed; a thick-walled disk-shaped sleeve part 4 formed integrally with the central part of the spacer part 3; In the tooth portion 5 on the other end side of the body portion 2 , external teeth 6 are formed on the tooth portion 5 .

[0031] figure 1 The hat-shaped flexible external tooth gear 10 shown in (b) includes: a thin-walled cylindrical body portion 12 that can be flexed; The thin-walle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com