High-temperature fire clay for coke oven and recycling method of fire clay

A high-temperature refractory and refractory mud technology, applied in the field of refractory materials, can solve the problems of weakening the plugging effect of the coke oven coal filling hole cover, increasing costs, wasting resources, etc., and achieving the effects of reducing the amount of purchases, reducing the amount of use, and saving resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] A preferred embodiment of the high-temperature refractory mud for coke ovens and its recycling method of the present invention will be described in detail below.

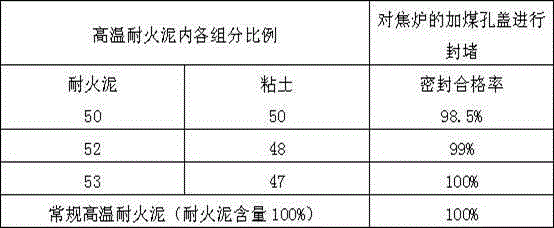

[0016] A specific embodiment of the high-temperature refractory mud for coke ovens of the present invention: the high-temperature refractory mud for coke ovens is composed of clay and refractory mud; the ratio of each component is: clay: 47-50% (wt%), Refractory mud: 50-53% (wt%).

[0017] Refractory clay, also known as fireclay or joint material, is used as a joint material for refractory product masonry. Refractory mud can be divided into clay, high alumina, silicon and magnesium refractory mud according to the material.

[0018] Clay refers to the sticky soil with few sand grains. It is not easy for water to pass through it, and it has good plasticity. It is not only easy to integrate with refractory mud to form new high-temperature refractory mud, but also is cheap and easy to obtain.

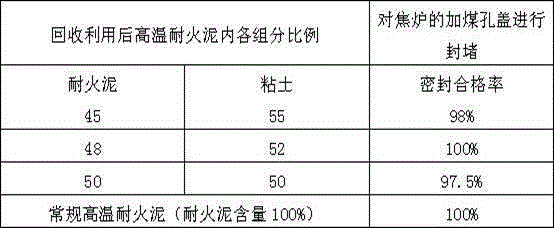

[0019] After man...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com